In oil and gas applications, reliability and safety are essential. To support the industry’s highly regulated, mission-critical operations, John Crane offers a wide range of innovative services and applied engineering solutions. Our experienced sales and engineering staff help select, design and apply sealing systems for even the most challenging conditions, and John Crane products meet the highest industry standards for containment of fugitive emissions. We also have 90+ test rigs available to ensure components can operate with maximum reliability when subjected to specific environmental conditions. And with more than 200 global rapid-response locations, assistance is available whenever and wherever our customers need it.

Recommended for You

Upstream — Oil and Gas Extraction

Offshore platforms and onshore oil and gas extraction facilities often operate in remote locations where storage space is limited and application conditions are extreme. And because equipment failure can have dire consequences — jeopardizing costs, environmental safety and energy resources — these mission-critical operations require reliable engineered components that can withstand extreme temperatures, high pressures, corrosion and erosion over a long period of time. John Crane not only engineers products with proven long-term success under these conditions; we also offer a wide range of assistive services that help maximize application reliability.

Midstream/Downstream — Processing, Pipelines and Refining

Due to the volatile and hazardous nature of midstream and downstream oil and gas materials, every pump, compressor, turbine and mixer depends on innovative engineered components to optimize safety and emission containment. John Crane engineers products specific to abrasive conditions, pressure changes, and multi-phase fluid properties to maximize uptime and minimize emissions. If service, repair or refurbishment are ever needed due to planned or unplanned maintenance, we also have over 200 global rapid-response locations ready to dispatch specialized assistance at any time.

Oil and Gas Industry Services

We also offer deliver reliability through a number of additional services:

Maintenance and Repair Services

John Crane’s Maintenance and Repair Services assists with critical systems checks and plant equipment maintenance as well as repair, removal and reinstallation services.

Learn moreMechanical Seals Reliability Programs

John Crane’s Mechanical Seals Reliability Programs assess equipment reliability and performance, analyze root cause failures and recommend strategies for improvement.

Learn moreAsset Management Solutions

John Crane’s Asset Management software offers customers a holistic view of their current systems to help spot unleveraged opportunities.

Learn moreProduct Training

John Crane provides a wide range of training courses that cover the correct procedures for installing, operating and maintaining equipment components.

Learn moreOil and Gas Products

Showing 1–52 of 52 products

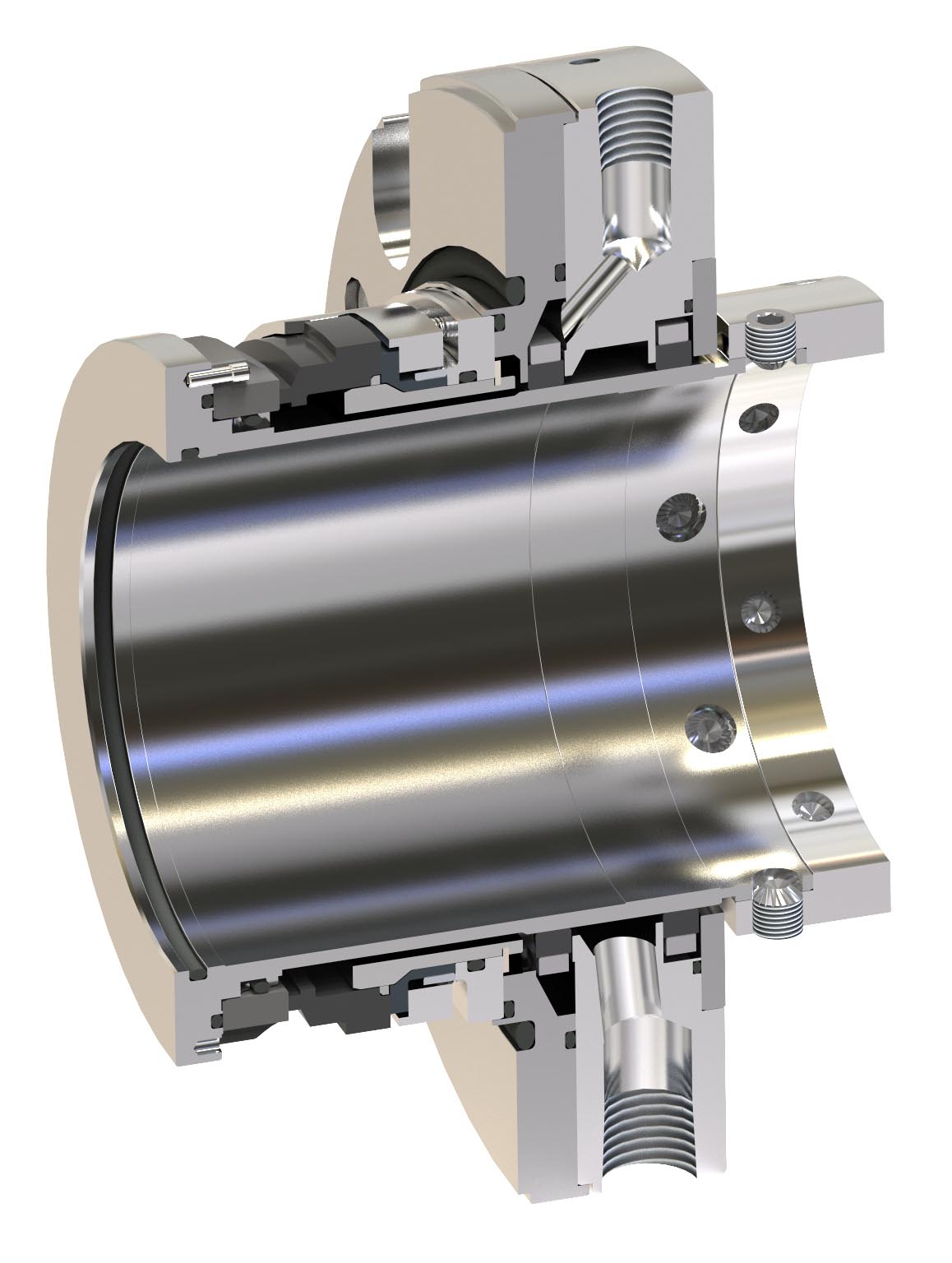

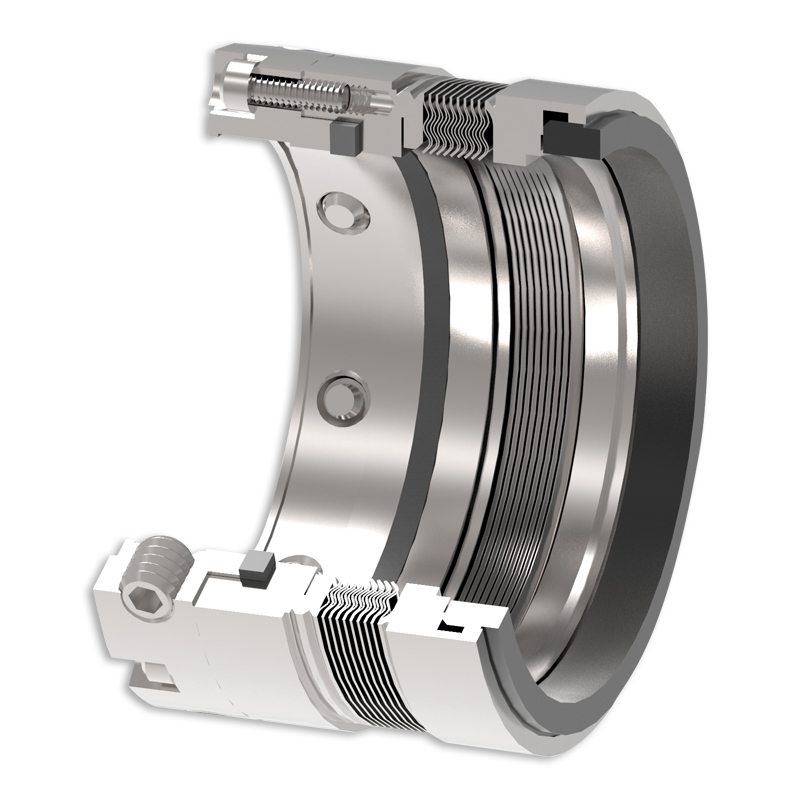

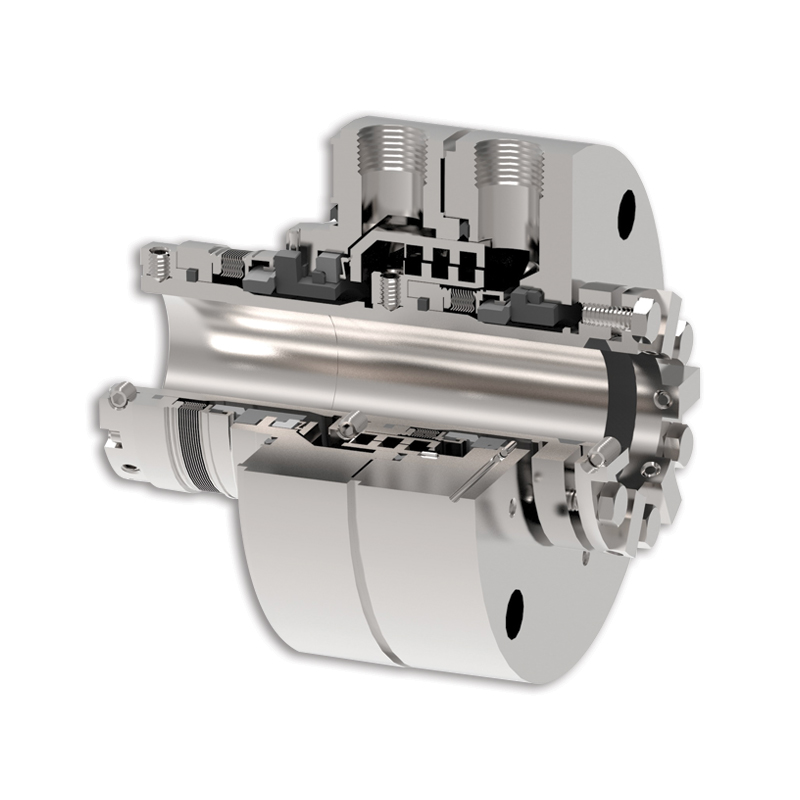

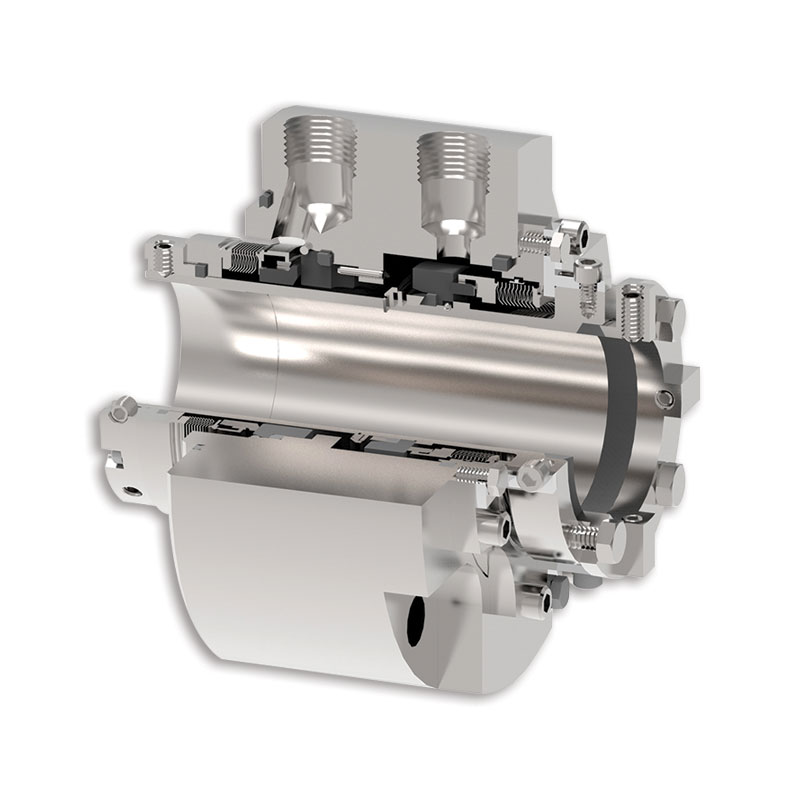

Type 8648VRS

Single and Dual Non-pusher Elastomer Seal

Type 8648VRS is a standardized non-pusher elastomer mechanical seal using patented technology, designed specifically for difficult hydrocarbon oil pipeline applications. It is designed specifically with…

Type 48LP

Low-emission, Low-pressure O-ring Shaft Seal for Light Hydrocarbon Services

Type 48 seals evolved from the successful, proven John Crane Type 8B1 design, the preferred choice for safe, reliable, unpressurized...

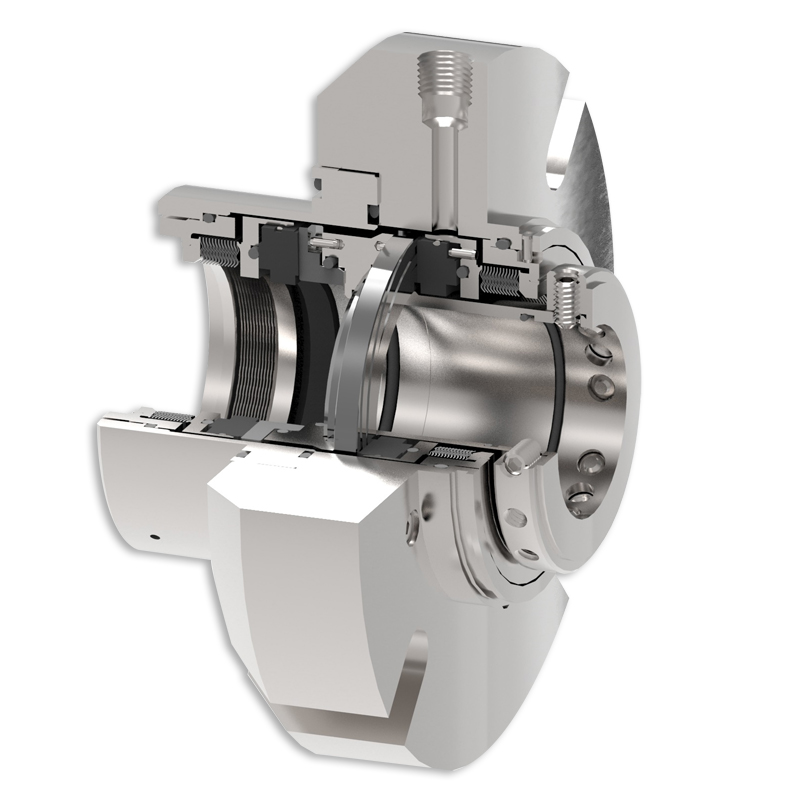

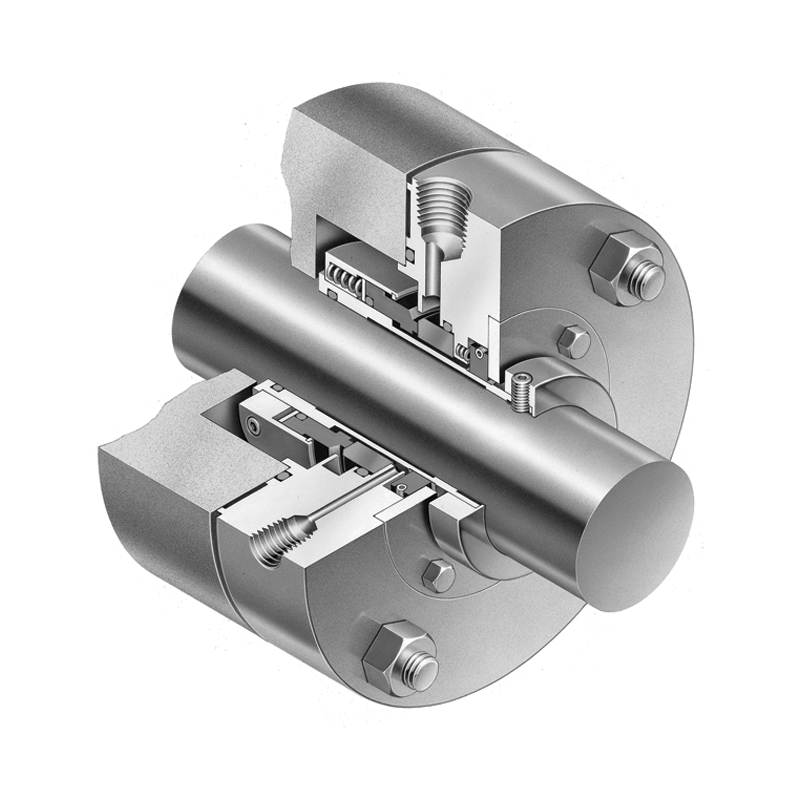

O-ring Pusher Seals

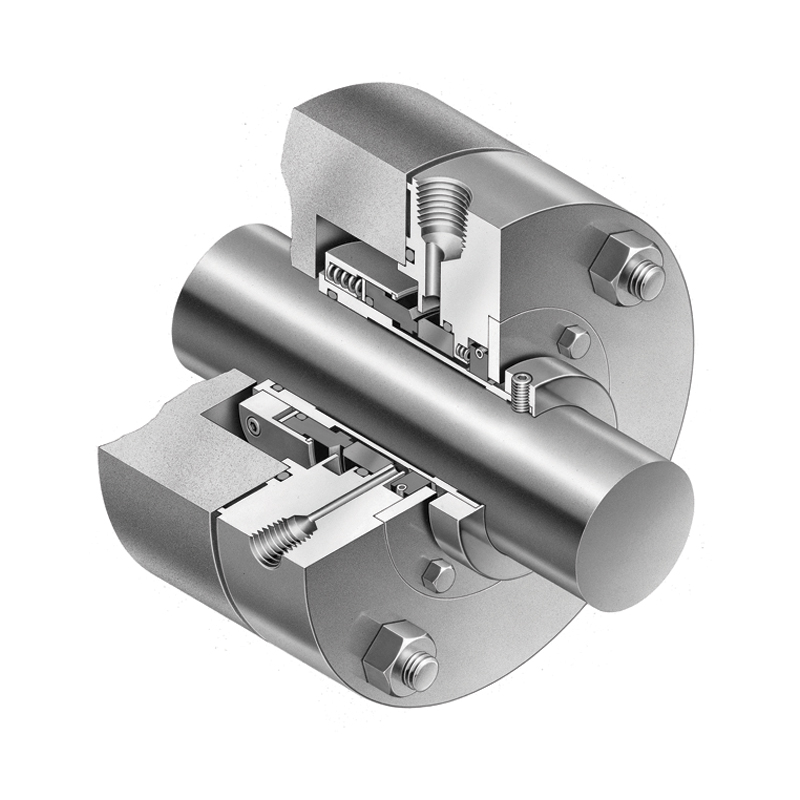

Type RREP / RRDP

High-performance Multi-spring Seal

Designed for high-pressure and high-speed applications, the RREP is suited to a whole host of refinery and process industry duties,...

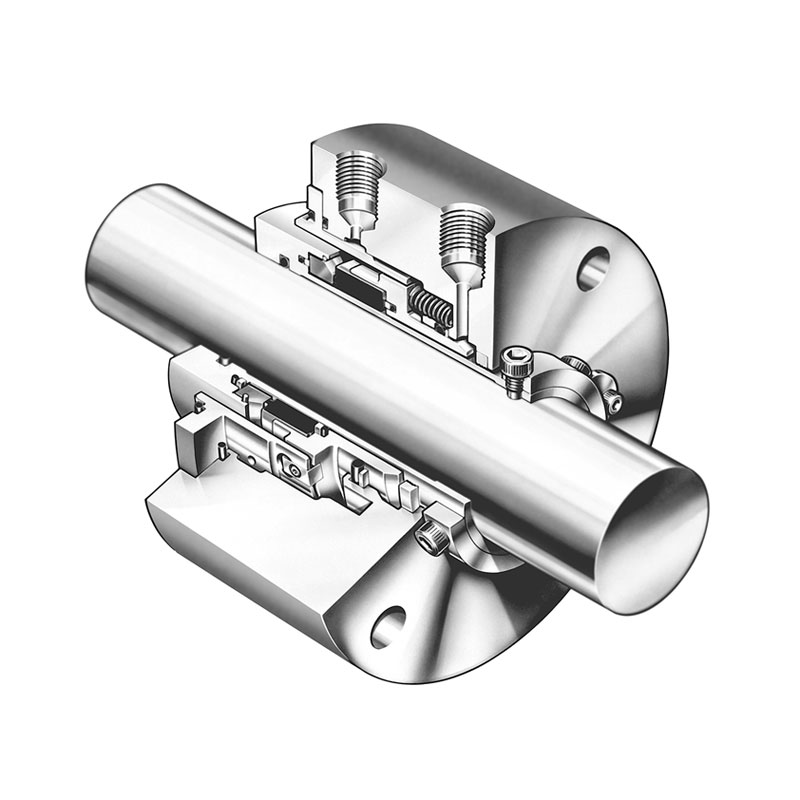

Type 5610/5610Q/5610L

Universal Cartridge Seal Family — Single Cartridge O-Ring Seal

The first truly universal cartridge seal, the Type 5610 will change your approach to sealing. Since the 5600 Series components...

Type 604

High-temperature, Stationary Edge-welded Metal Bellows Seal

The Type 604 is a high-temperature, general-purpose, stationary edge-welded metal bellows assembly for applications to 425C/800F. Available in either AM350...

Type 606

High-temperature, Rotating Edge-welded Metal Bellows Seal with Drive Lugs

The Type 606 is a high-temperature (to 425°C/800°F) rotating seal with the same high-strength design features as the Type 609....

Type 609

High-temperature, Rotating Edge-welded Metal Bellows Seal

The Type 609 is a high-temperature (to 425°C/800°F) rotating seal head assembly that incorporates all of the rugged features of...

Type 670

Low-temperature, All-Alloy C-276 Metal Bellows Shaft Seal for Highly Corrosive Fluids

The Type 670 is an all-Alloy C-276 rotating bellows seal, providing high strength and excellent corrosion resistance. It is...

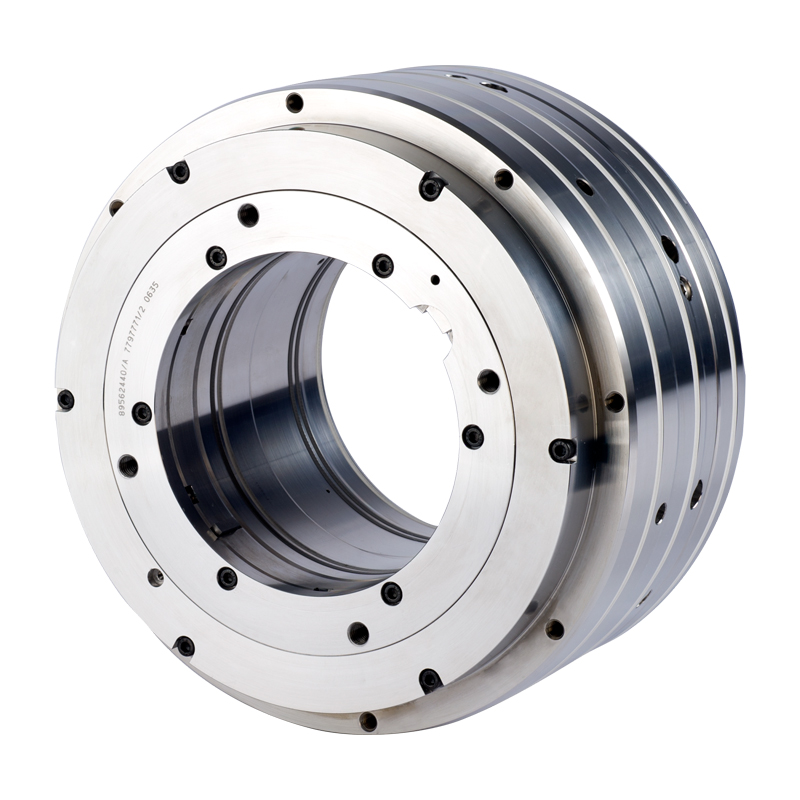

Type 2800MB

Welded Metal Bellows Gas-lubricated, Non-contacting, Dual Cartridge Seal with Elastomeric Secondary Seals

The Type 2800MB is a state-of-the-art welded metal bellows, gas-lubricated, non-contacting seal for achieving 0.0 fugitive emissions for Maximum...

Type 2874

Non-contacting Dual Gas Seal Cartridge for Pumps

The Type 2874 is an internally pressurized, gas-lubricated, non-contacting dual cartridge seal designed for use in API, ANSI and DIN...

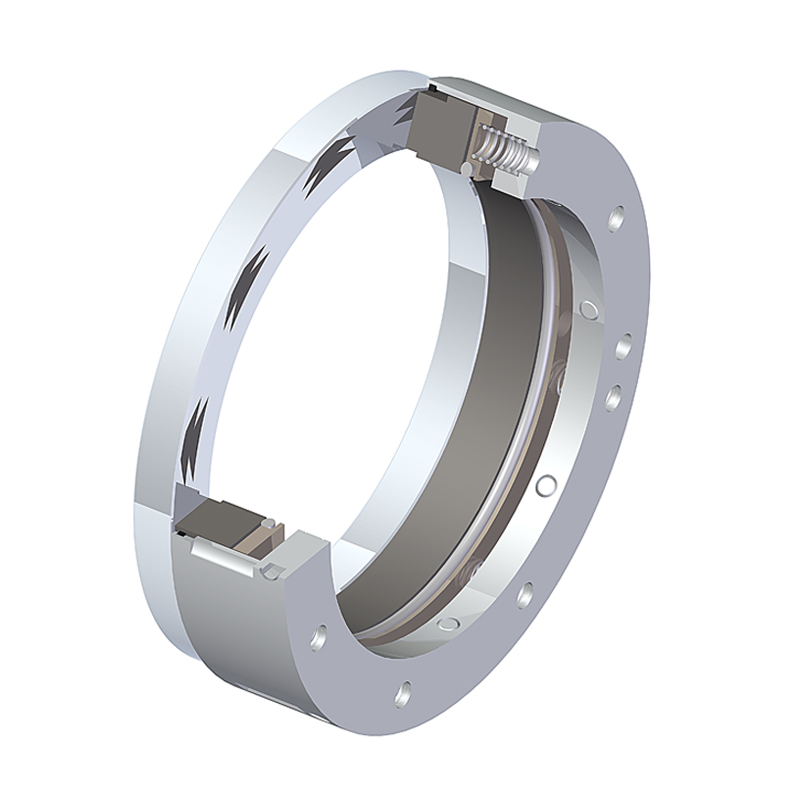

Type 28SC

Non-contacting Secondary Containment Seal

The 28SC is a gas-lubricated, non-contacting secondary containment seal, which is applied as a component of a multiple seal...

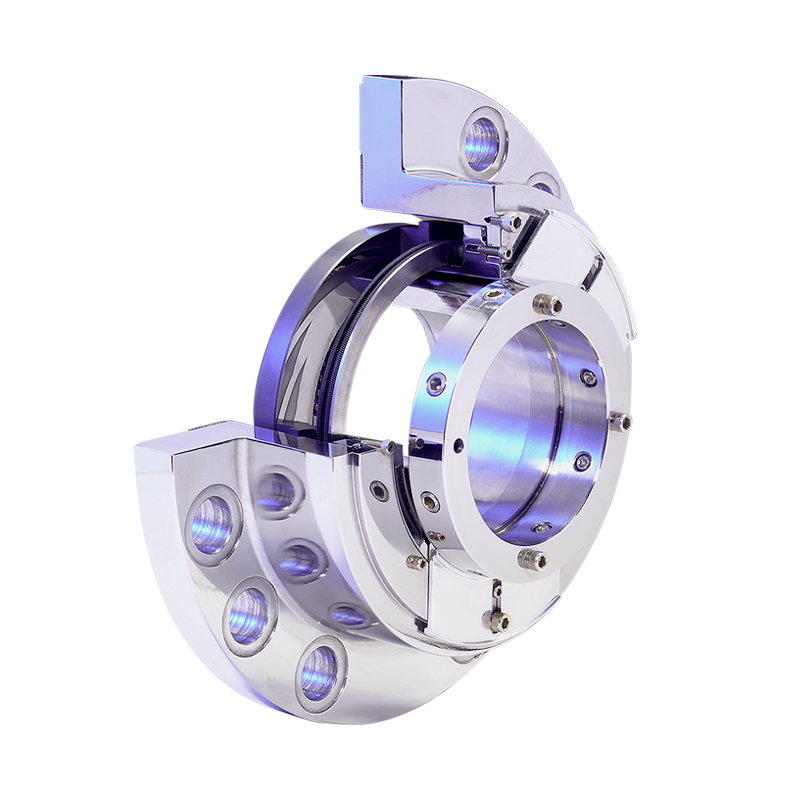

Aura®

The Next Generation of John Crane Gas Seals

Aura® reduces operational and transactional costs using a patented polymeric sealing device.

Type 28ST

Non-contacting Gas Seal for Steam Turbines

Type 28ST combines proven rotating groove technology and high-temperature secondary seals to reduce steam leakage by nearly two orders of...

Type 1648

API 682-qualified, Single Cartridge, Type "A" O-ring Pusher Seal

The Type 1648 is a high-performance single cartridge pusher seal designed to help prevent emissions leakage in most refinery applications....

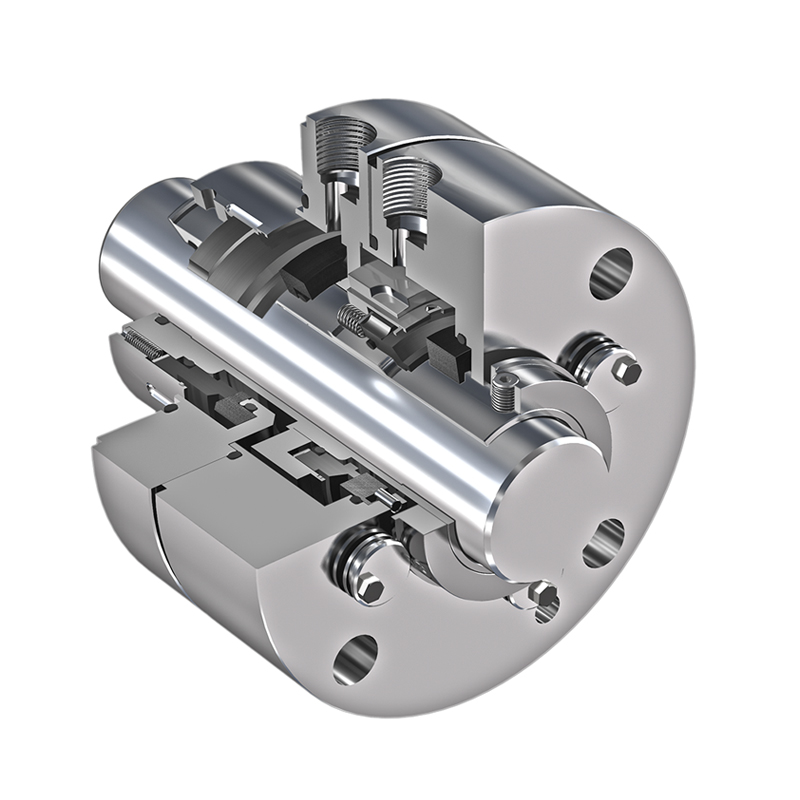

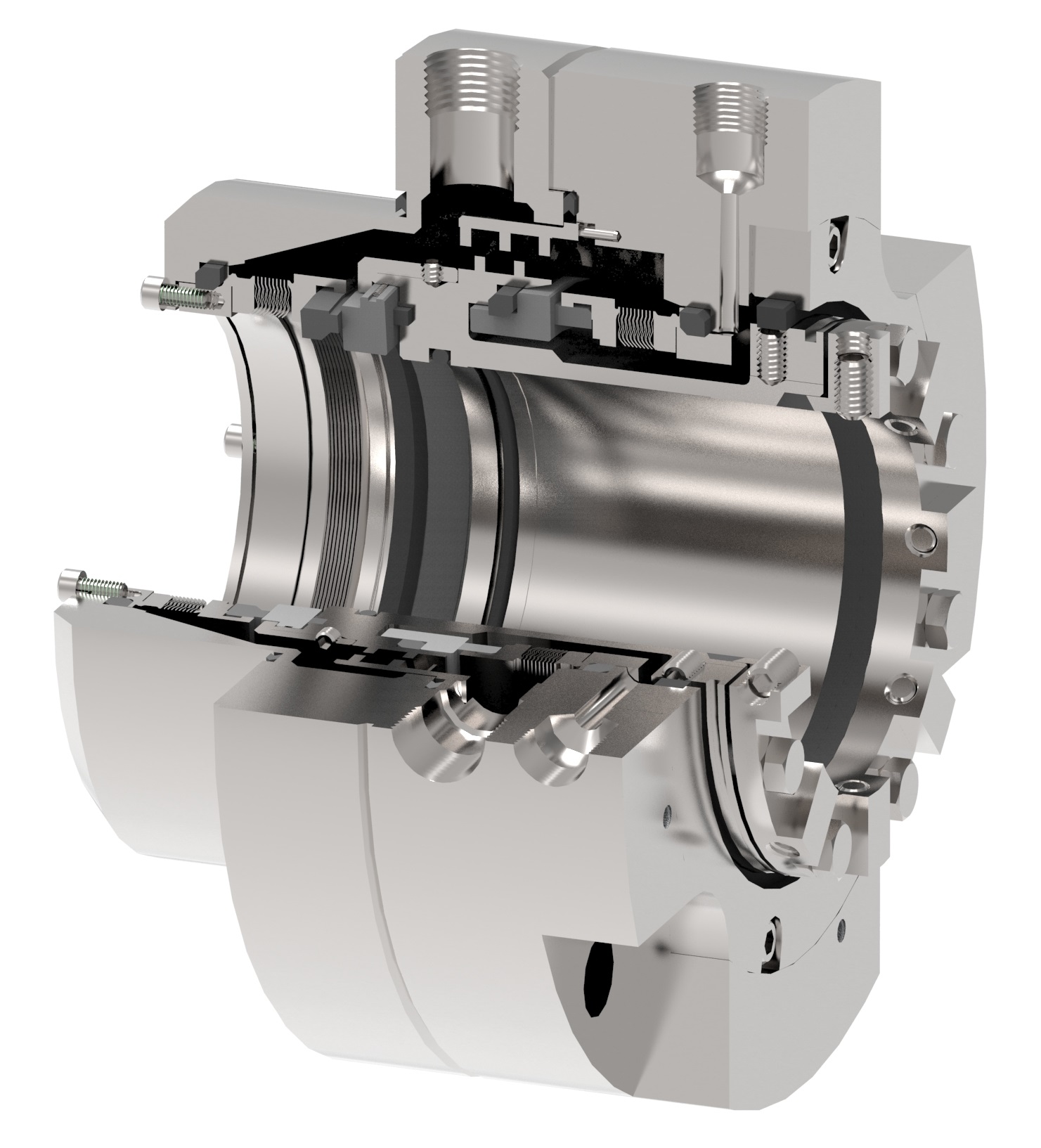

Type 2648

API 682-qualified, Dual Unpressurized Cartridge, Type "A" O-ring Pusher Seal

The Type 2648 is a high-performance, low-emission cartridge seal designed to provide additional safety for hazardous applications and applications where...

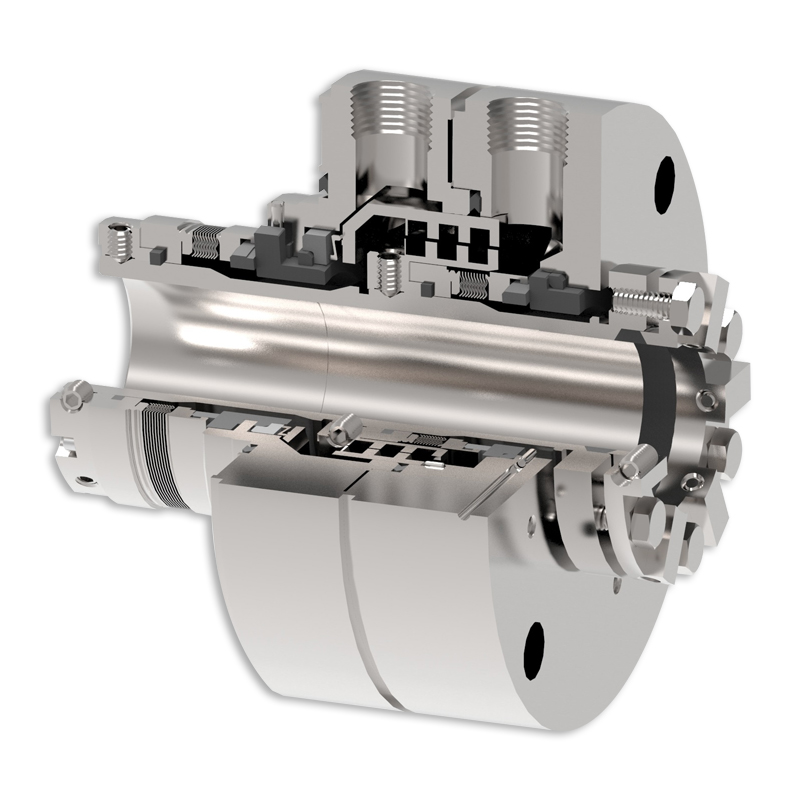

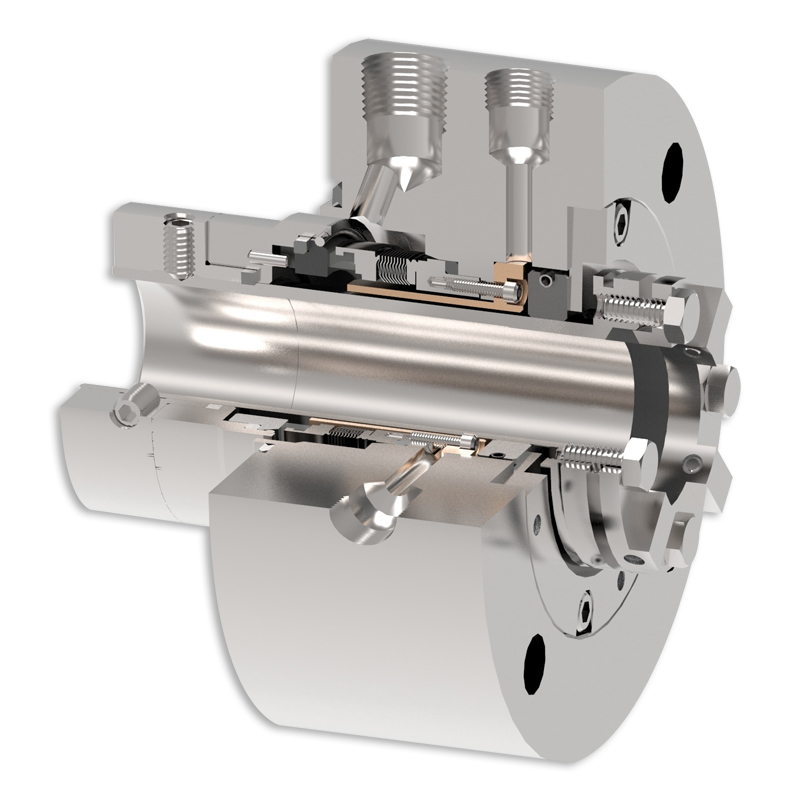

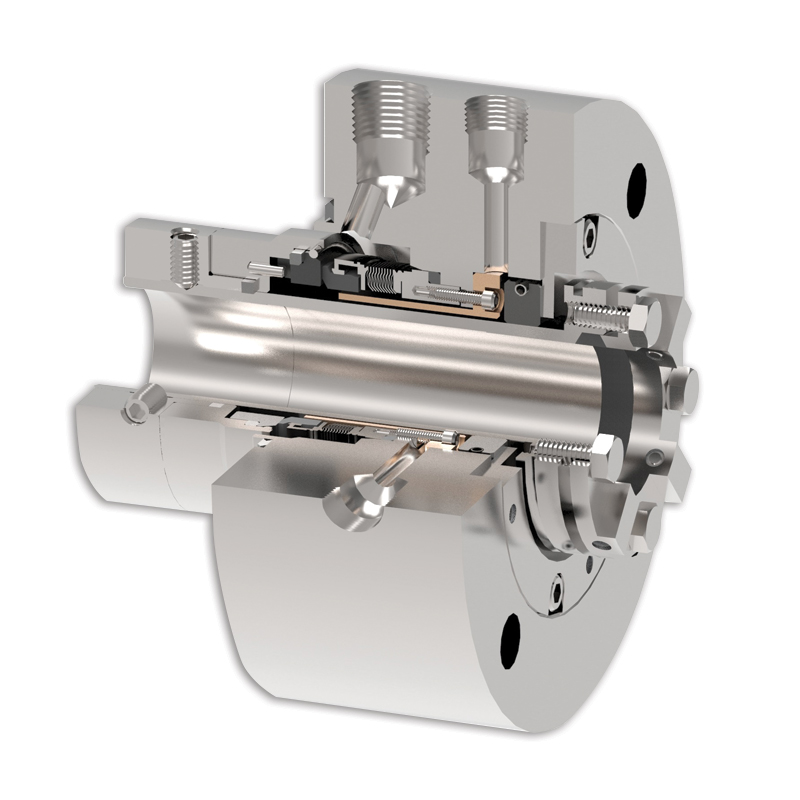

Type 3648

API 682-qualified, Dual Pressurized Cartridge, Type "A" O-ring Pusher Seal

The Type 3648 is a high-performance, low-emission cartridge seal designed for maximum containment of hazardous fluids and light hydrocarbons. Its...

Type 1670

API 682 Category II and Category III, Type B, Arrangement 1 Single Rotating Metal Bellows Cartridge Seal

The Type 1670 is a factory pre-set edge-welded metal bellows API 682 qualified cartridge seal with Alloy C-276 (UNS N10276)...

Type 2609HTL/3609HTL

Dual Unpressurized and Pressurized Rotating Bellows Cartridge Seals (API 682 Type C, Arrangement 2 and 3)

Type 2609HTL is a dual unpressurized rotating bellows cartridge seal API 682 Type C, Arrangement 2. Type 3609HTL is a...

Type 2609HTC/3609HTC

Dependable API 682 Cartridge Seals

The Type 2609HTC and Type 3609HTC are dependable API 682 cartridge seals that utilize two impressive design innovations by...

Type 3604/3604HTC/3604HTCDP

API 682 Type C, Arrangement 3, Stationary Metal Bellows Cartridge Seal

The Type 3604/3604HTC/3604HTCDP is a highly reliable dual face-to-face stationary cartridge seal for high-temperature refinery services that is fully API...

Type 1604

Single Stationary API 682 Metal Bellows Cartridge Seal Type C, Arrangement 1

The Type 1604 high-temperature, high-performance Type C, Arrangement 1, API 682 qualified cartridge seal is designed for high-temperature applications such...

Type 1604HTC

Single Stationary Welded Metal Bellows API 682 Cartridge Seal Type C, Arrangement 1

The Type 1604HTC is an API 682 qualified single stationary bellows cartridge seal Type C, Arrangement 1. The Type...

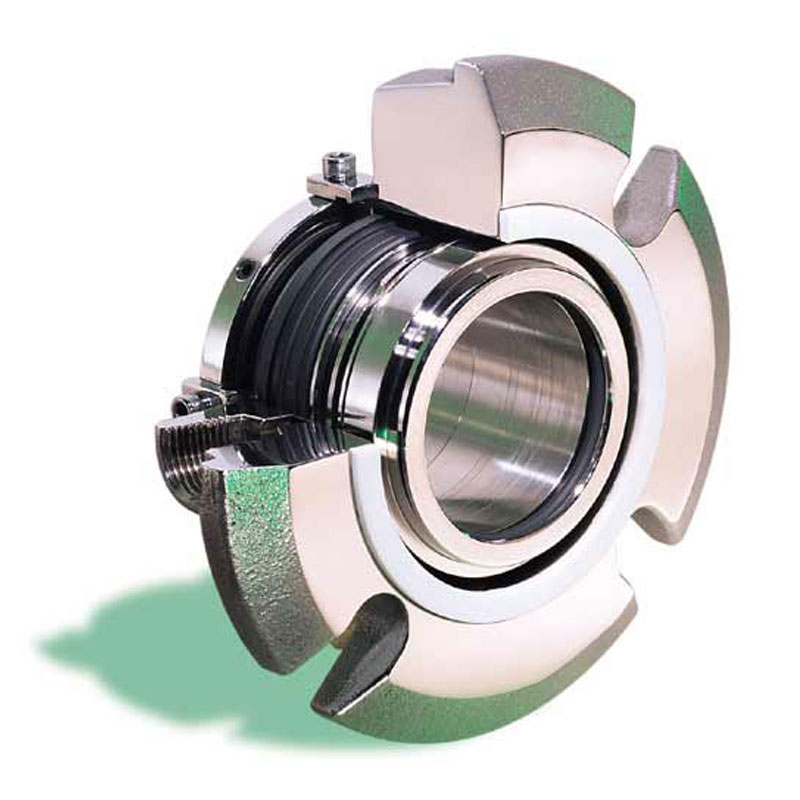

ECS®

Metal Bellows Dry-running Secondary Emission Containment Seal

Available in low- and high-temperature designs, the ECS® is a dry-running seal for emission containment and safety/backup that successfully controls...

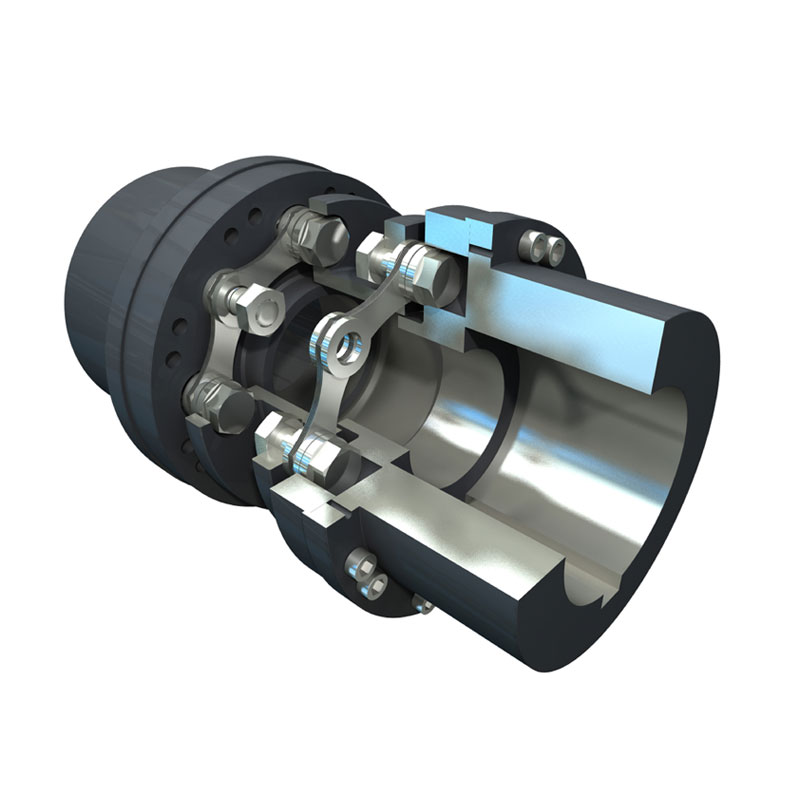

MHS Series

M Series Multiple Membrane Straight Diaphragm Coupling with Stainless Steel Discs in Pre-assembled Single Diaphragm Packs

With John Crane’s Metastream® MHS Series coupling range, the torque is transmitted through pre-assembled packs with a built-in safety bush...

TDK/TSK/TLK

T Series Stainless Steel Discs in Pre-assembled Cartridge for Medium to High Torque Applications (Metric)

John Crane’s Metastream TDK/TSK/TLK Series are metallic membrane (disc) couplings, incorporating industry...

A Series Close-coupled Arrangement

Close-coupled Wrap-fit Urethane Element Coupling

John Crane A Series couplings provide a solution to one of the most persistent and troublesome problems facing maintenance personnel: periodic...

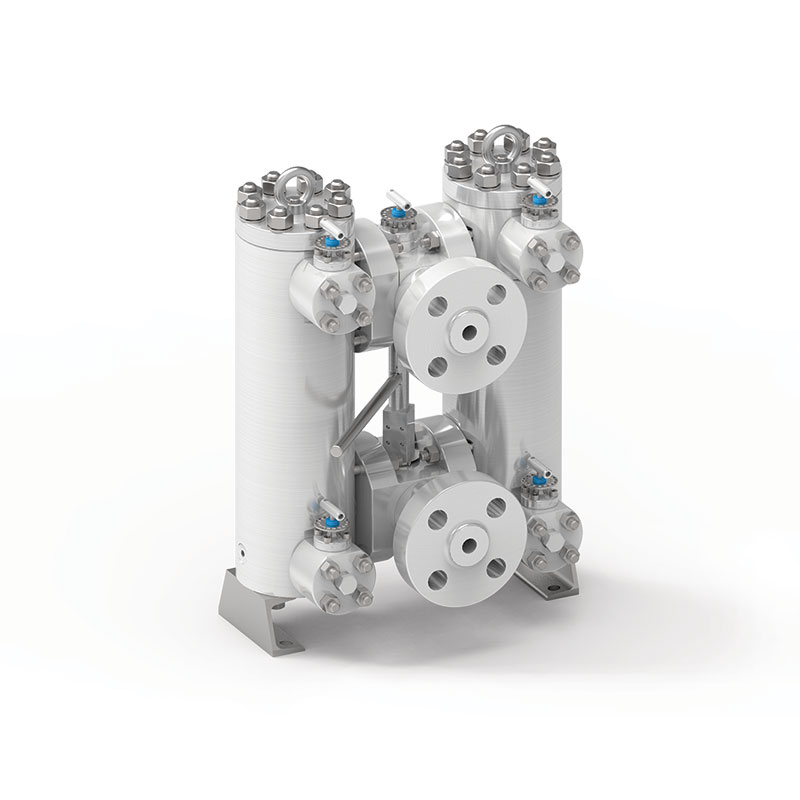

PR 52/PR 53A

Reservoirs

These reservoir-based seal support systems are designed for both API Plan 52 and 53A applications to support unpressurized and pressurized...

PA 53B

Accumulator-based System

53B accumulator-based seal support systems utilize a bladder to maintain system pressure to pressurized dual seals and absorb barrier fluid...

PA 53C

Accumulator-based System

53C accumulator-based seal support systems utilize a piston to maintain system pressure to pressurized dual seals and absorb barrier fluid...

RU-2/RU-4

Mobile Refilling Units

Portable units enable refilling of a seal reservoir or buffer/barrier fluid circuit while...

PL 54/55

Lubrication Systems

PL 54/55 lubrication systems provide a positive flow and pressure of pressurized or unpressurized barrier/buffer fluid to dual seals. This...

WCH

Water-cooled Heat Exchangers

Water-cooled heat exchangers may be applied where water is readily available. Heat exchangers may be packaged together with seal support...

WCV

Water-cooled Heat Exchangers

Water-cooled heat exchangers may be applied where water is readily available. Heat exchangers may be packaged together with seal support...

K2S

Water-cooled Heat Exchangers

Water-cooled heat exchangers may be applied where water is readily available. Heat exchangers may be packaged together with seal support...

PD 75

Leakage Detection

Used to detect and monitor leakage of the inboard seal, these seal support systems can detect liquid leakage (API Plans...

PD 76

Leakage Detection

Used to detect and monitor leakage of the inboard seal, these seal support systems can detect liquid leakage (API Plans...

PD 65A/PD 65B

Leakage Detection

Used to detect and monitor leakage of the inboard seal, these seal support systems can detect liquid leakage (API Plans...

PG 72

Gas Panels

Used to provide a clean, regulated gas supply to a dual unpressurized seal arrangement where the containment seal is dry...

PG 74

Gas Panels

A PG 74 (API Plan 74) system provides a clean, dry, regulated supply of pressurized barrier gas...

Liquid Filtration

Filtration Solutions for Fluid Applications

John Crane’s Indufil® liquid filters can be applied to almost any liquid application, from hydraulic and bearing oil systems to lubrication and...

Seal Gas Filtration

Optimized Seal Gas Filtration for API 692

Specially designed John Crane’s Indufil® filters remove liquid and particle contamination and maximize reliable dry gas seal operation.

Fuel Gas Filtration

Fuel Gas Conditioning and Heating Equipment

John Crane’s Indufil® fuel gas filtration units are individually tailored to maximize reliability regardless of the condition of the supply gas. They...

Fuel Oil Filtration

Fuel Oil Purification Equipment

John Crane’s Indufil® complete fuel oil filtration systems are fitted as standard to many leading brands of gas turbines. Adequate filtration of...

Double 3-way and 6-way Transfer Valves

Ball Valves for Interlinking Heat Exchanger Equipment

John Crane's Indufil® ball valves are designed in-house and manufactured for use in duplex systems to enable continuous operation while one side...

Filter Elements

John Crane’s Indufil® Replacement Filter Elements

The performance of a filter unit is entirely dependent on the elements fitted, making it essential to fit genuine John Crane’s Indufil® ...

Process Filtration

Often your very method of production will introduce contamination to your process, whether from imperfect ingredients, necessary reagents or process equipment, and in order to…

1625G

High-temperature Graphite Braided Packings

John Crane styles 1625G are the ultimate in packing, offering the ability to perform in both...

1655C/1627/G57

High-temperature Carbon Braided Packings

John Crane styles 1627, 1655C and G57 are high-performance braided packing offerings which have the ability to perform in...

G57/G58/G58I

Braided Flexible Graphite Packing

G57, G58 and G58I are high-purity, high-strength interlace braided flexible graphite packings designed to handle a wide range of fluids....

894/1340

General-service Braided Graphite Packings

John Crane styles 894 and 1340 are cost-effective graphite general-service packing constructed of the highest-quality synthetic fibers and...

K1730/K1761/K1771

Abrasive Service Aramid and Meta-aramid Packings

John Crane styles K1730, K1761 and K1771 are constructed of high-tensile strength, abrasion-resistant fibers. Servicing a wide range of...