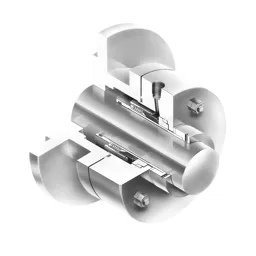

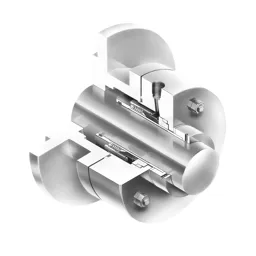

How Does a PTFE Wedge Seal work?

A PTFE wedge seal features a tough thermoplastic polymer sealing element in place of a traditional O-ring. This inert material provides excellent chemical, heat and high-pressure resistance and is commonly used where corrosive liquids, such as acids or solvents, are processed.

The PTFE wedge moves under pressure to maintain seal face contact, even during thermal expansion or shaft movement. This makes it highly effective in applications with wide temperature fluctuations, including both cryogenic and high-temperature environments.

Why Use a PTFE Wedge Seal?

Using a PTFE wedge seal offers distinct advantages over traditional elastomer O-ring seals.

- Excellent chemical compatibility: Inert to most corrosive chemicals, solvents and caustics.

- Wide temperature range: Performs in cryogenic conditions and high-heat processes.

- Minimised contamination risk: PTFE is non-leaching and non-reactive.

- Improved seal face stability: Maintains consistent pressure across varying operating conditions.

At John Crane, our PTFE wedge seals are engineered to address the challenges of dynamic sealing in industries such as chemical processing, pharmaceuticals and cryogenic systems. They are designed to allow precise sealing across a wide range of temperatures and shaft speeds, reducing downtime and improving operational reliability.