Which product is the best fit for your mining application?

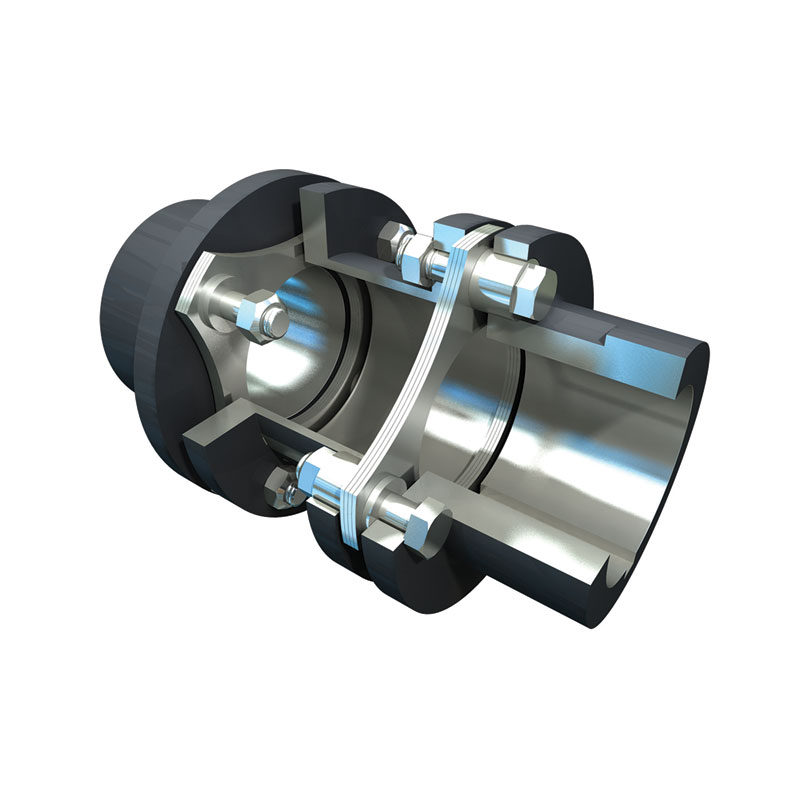

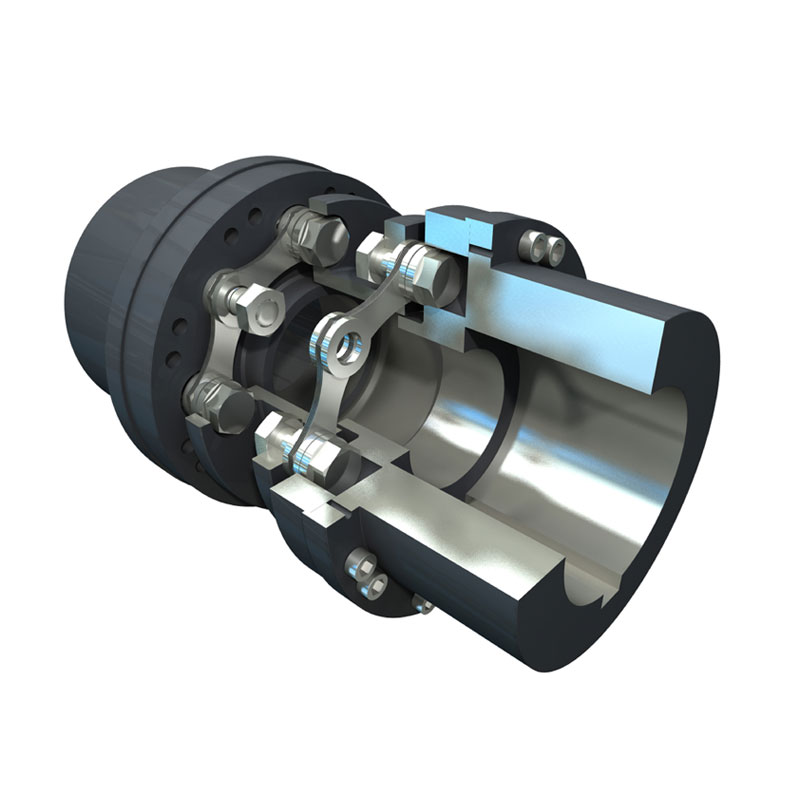

Mines are complex operations that use large amounts of water and harsh chemicals in a variety of methods. They use pumps to move liquids through the production process and drain underground water, compressors to carry gases and air, conveyors for transporting crushed ore, as well as autoclaves and agitators for the processing and breakdown of minerals. With all these different applications, choosing the right product is essential for maximizing the performance of each type of equipment. John Crane offers multiple products for each piece of equipment used in a mine.

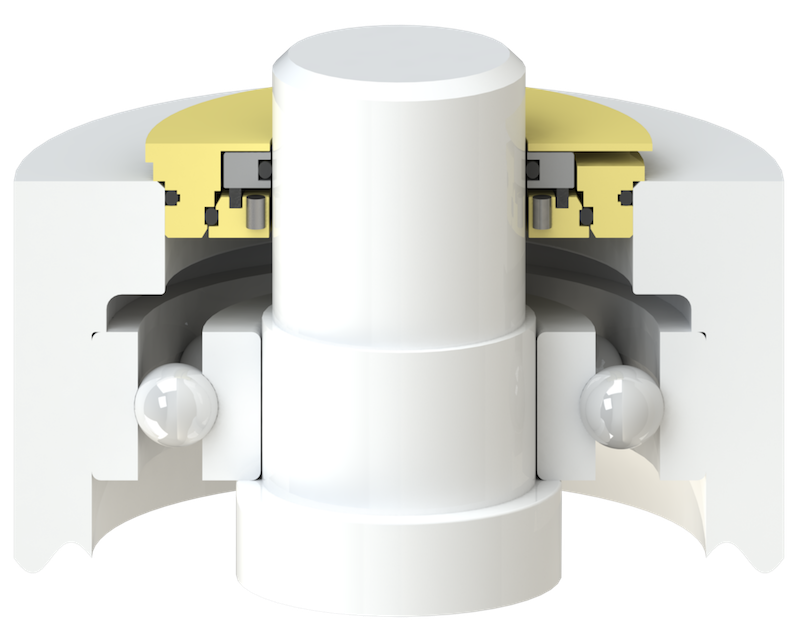

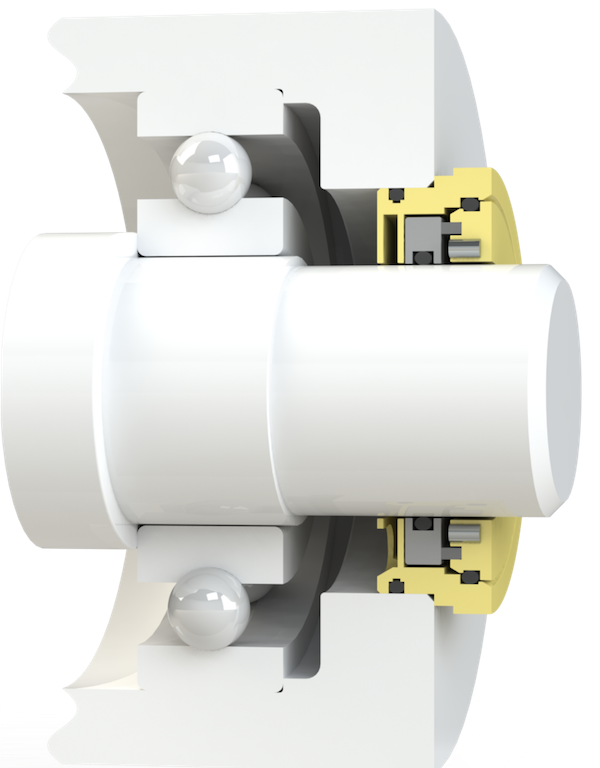

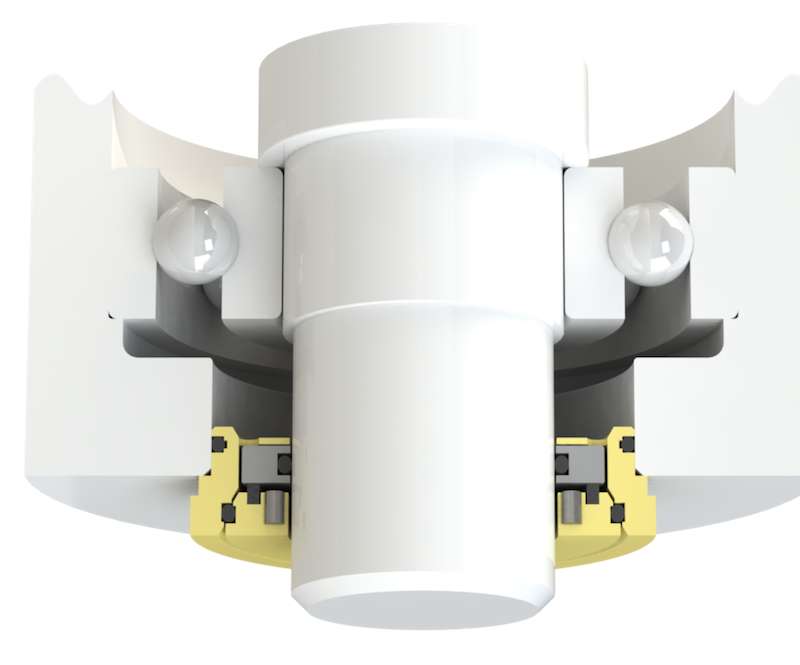

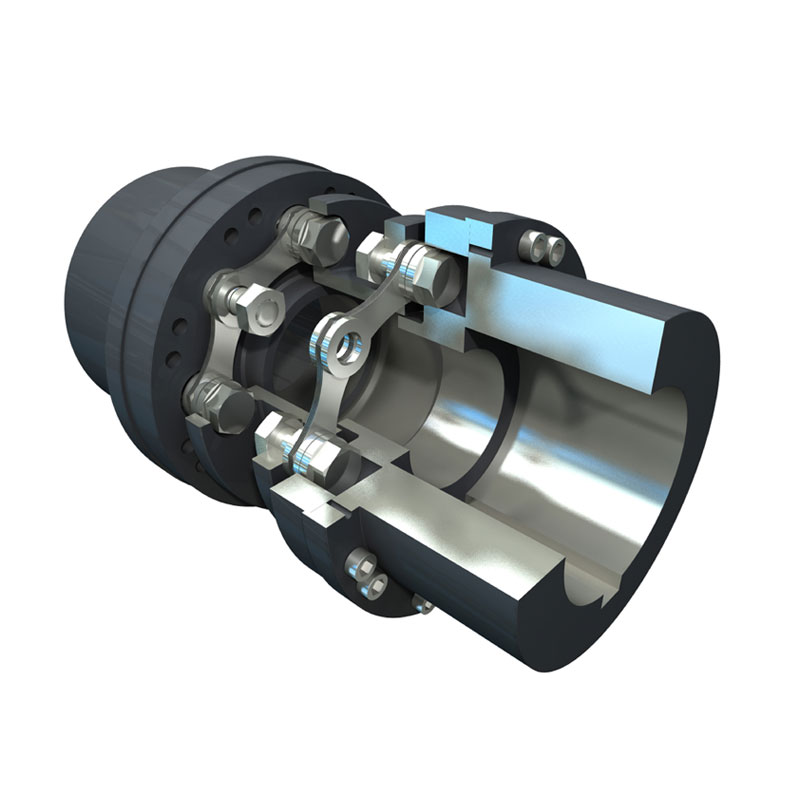

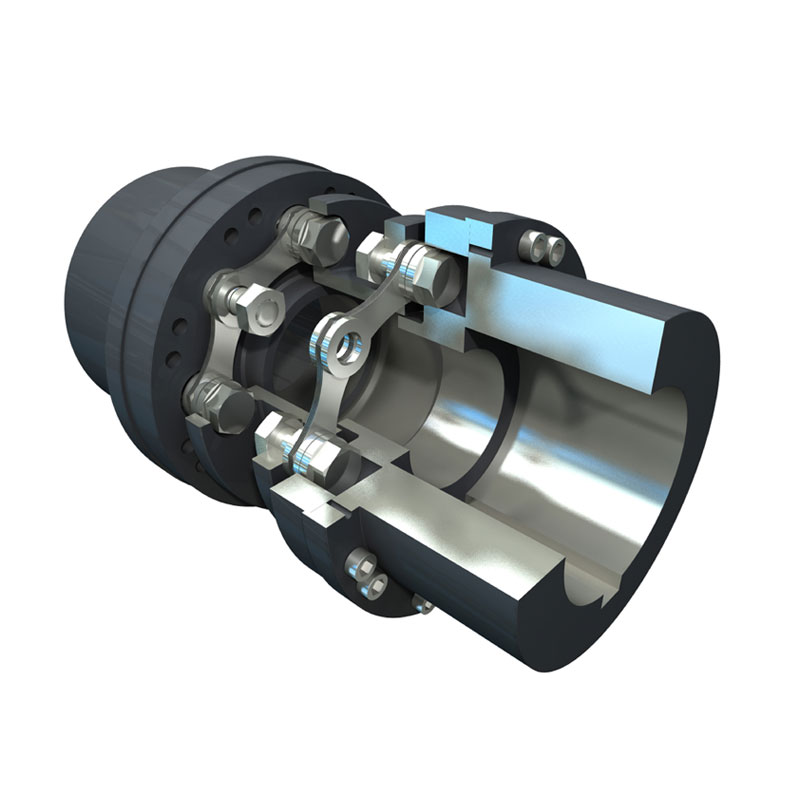

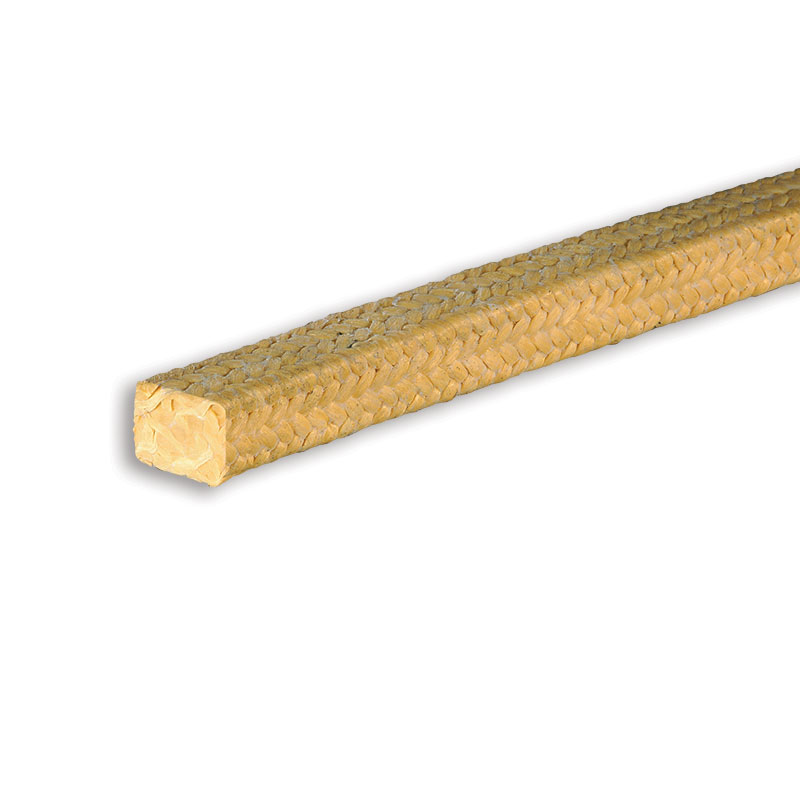

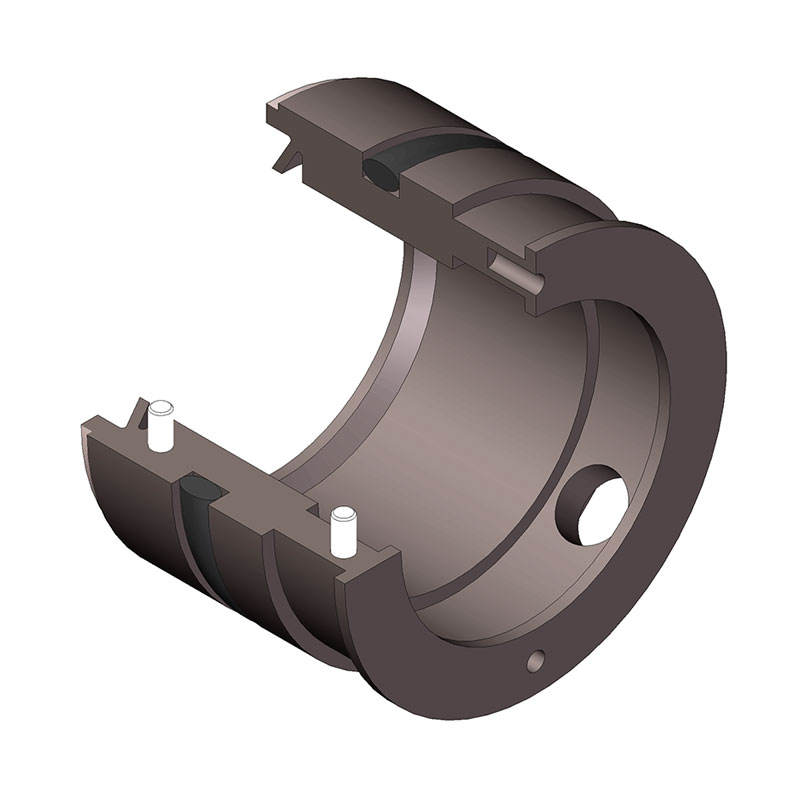

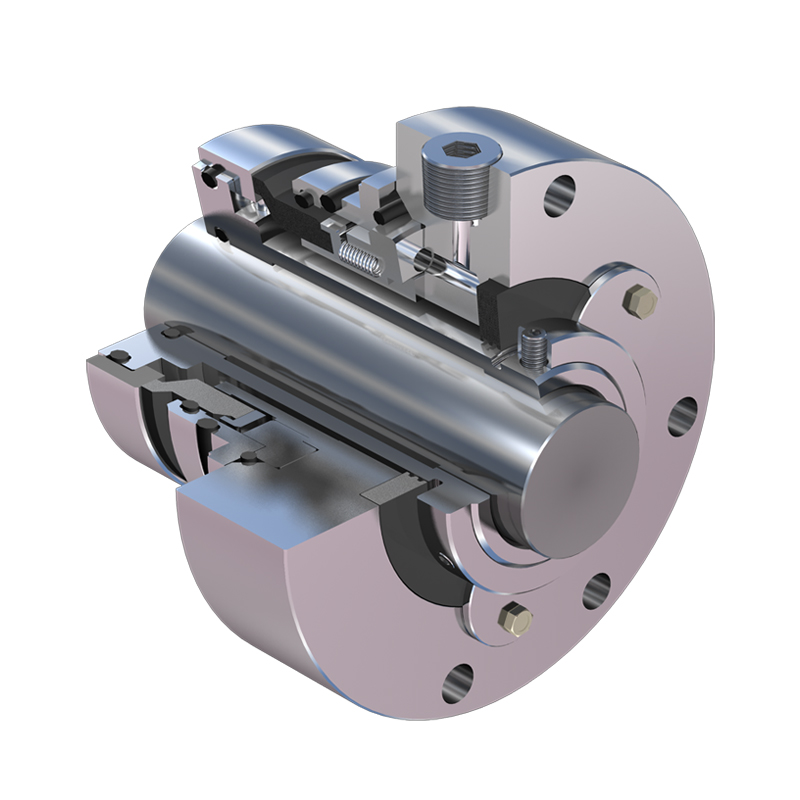

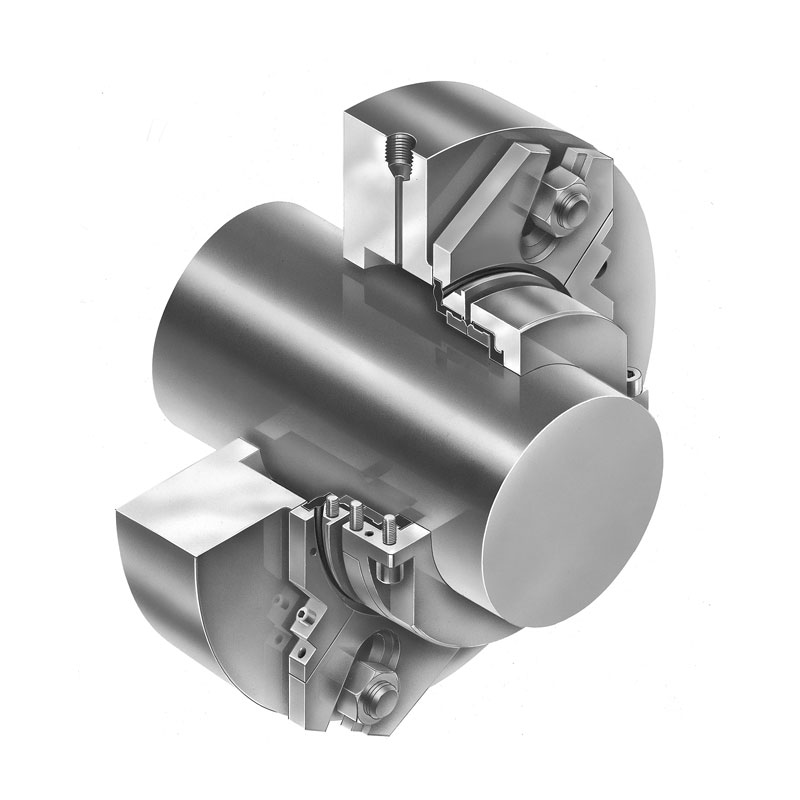

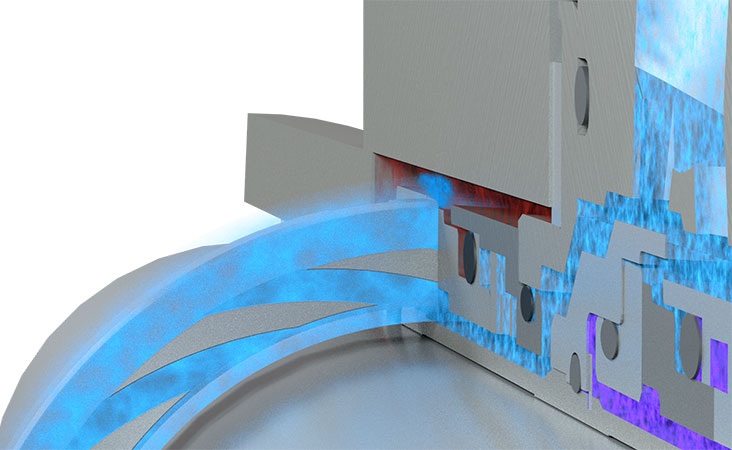

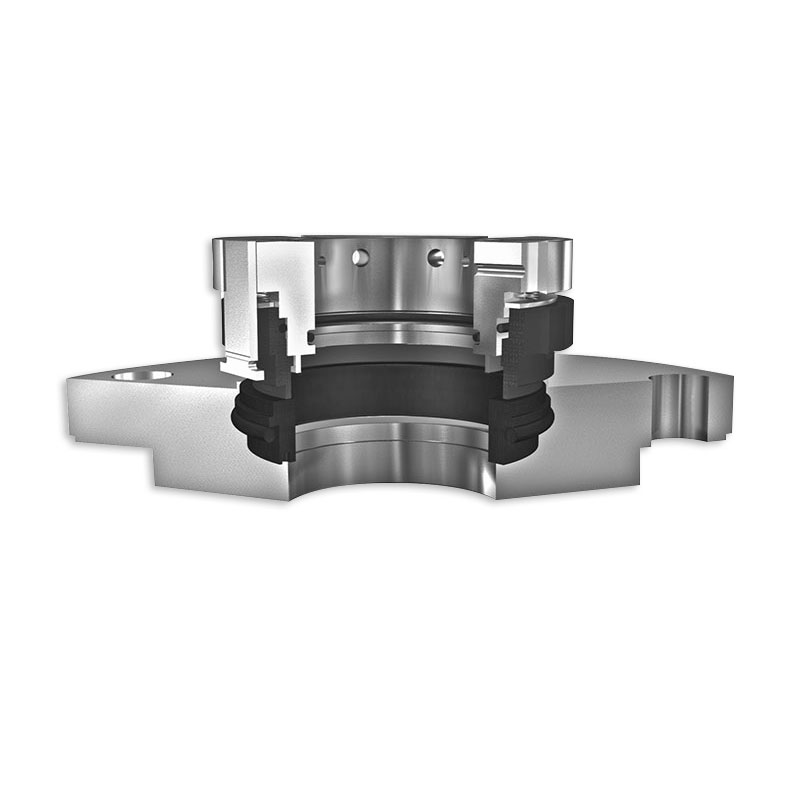

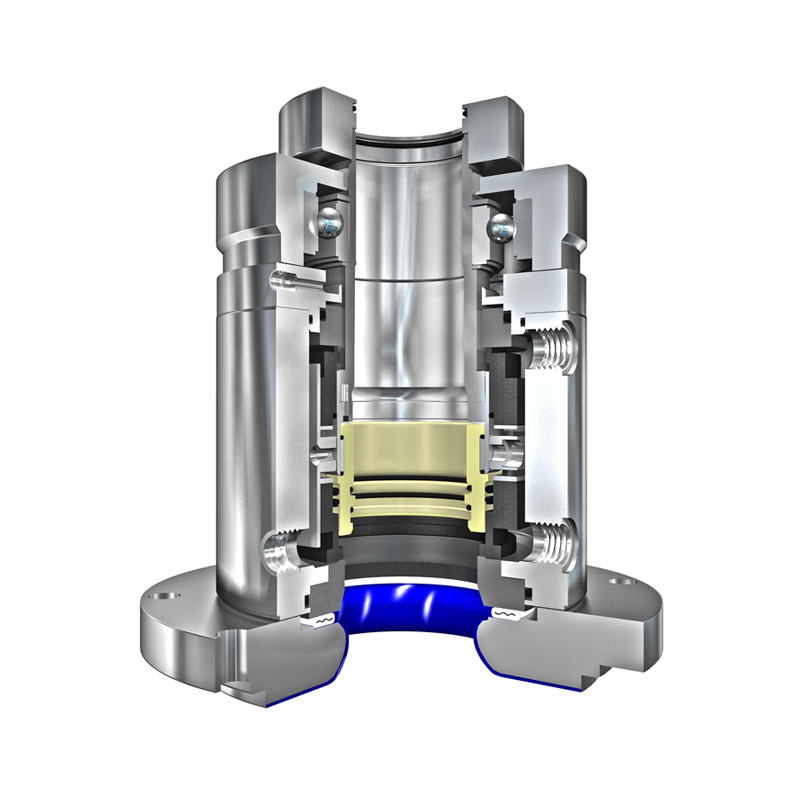

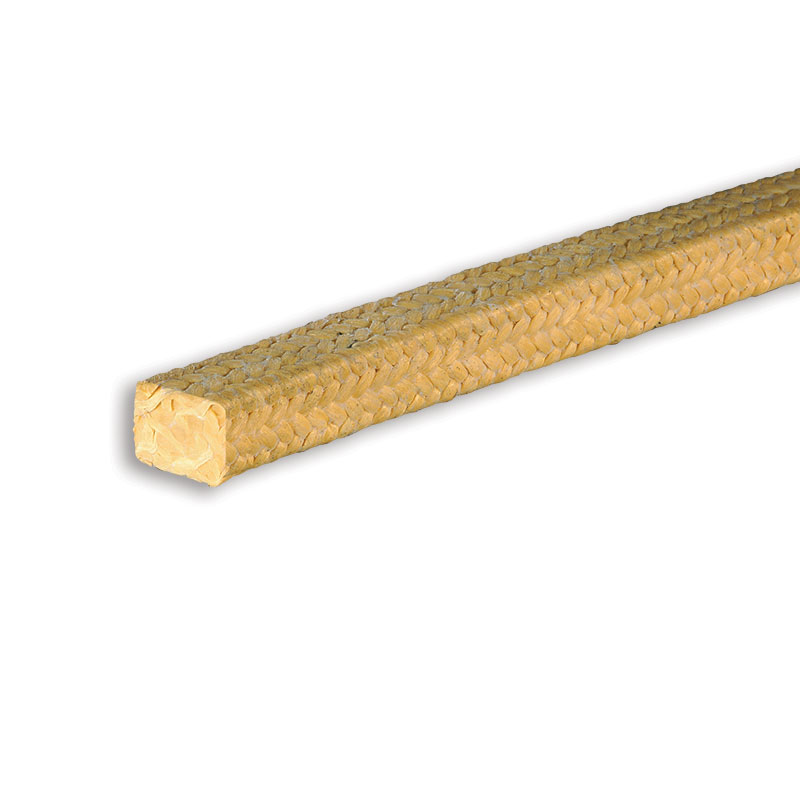

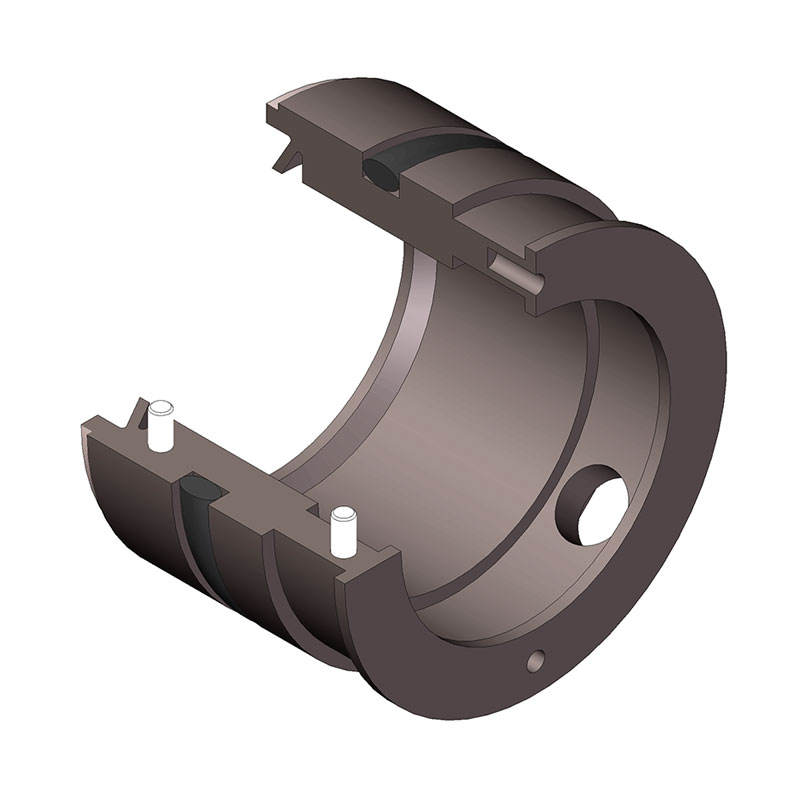

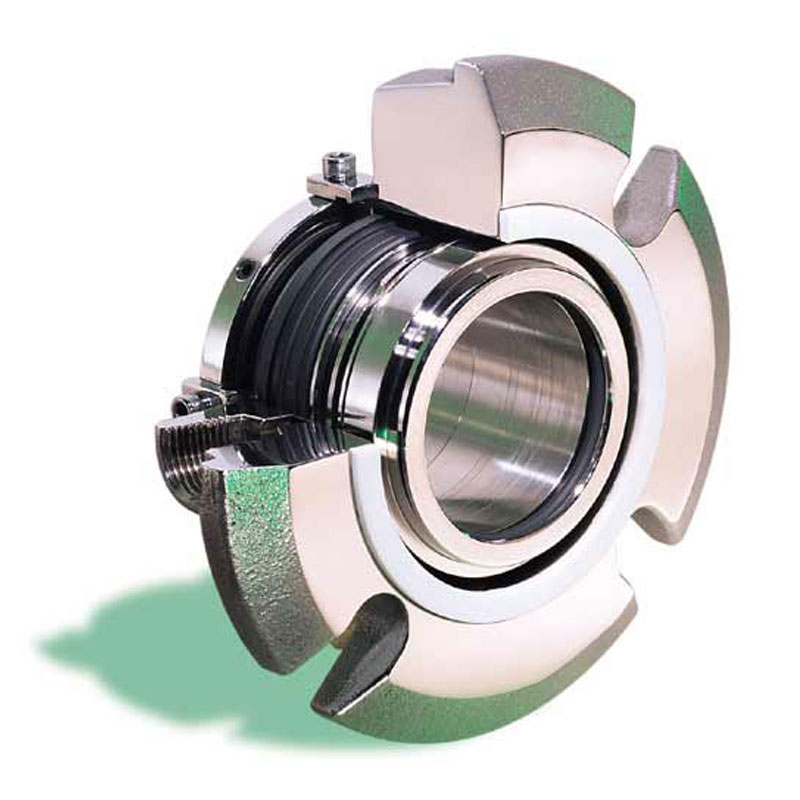

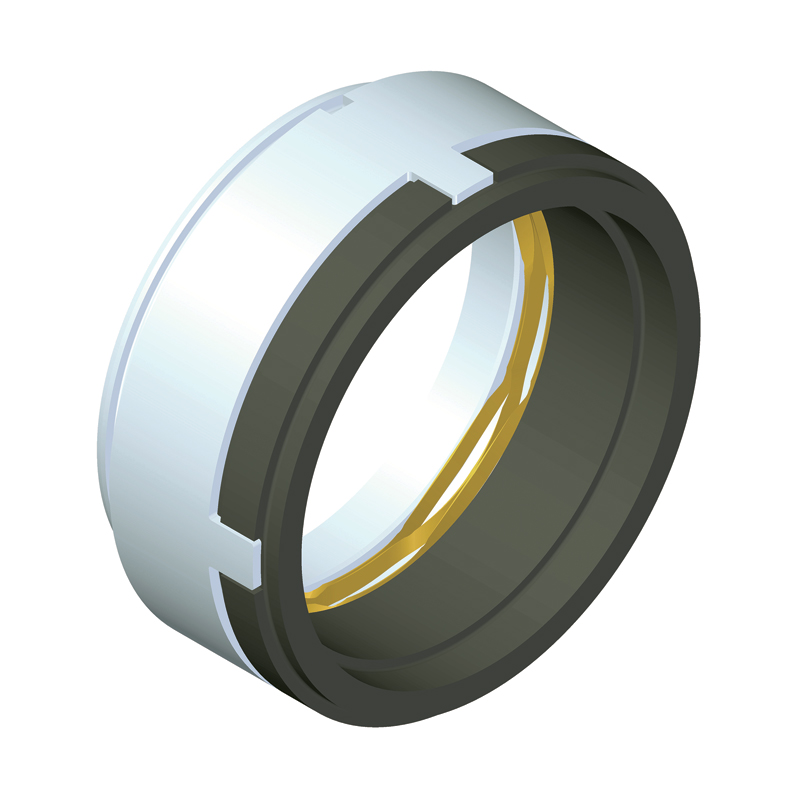

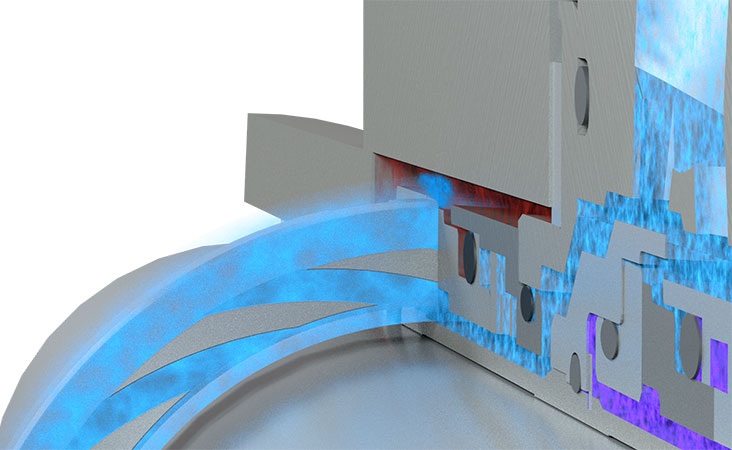

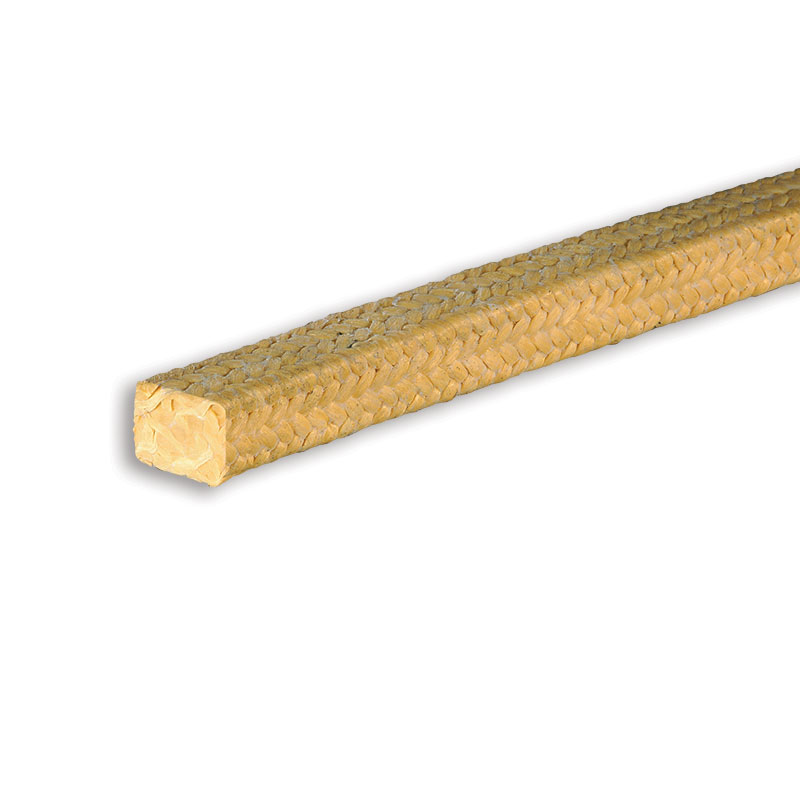

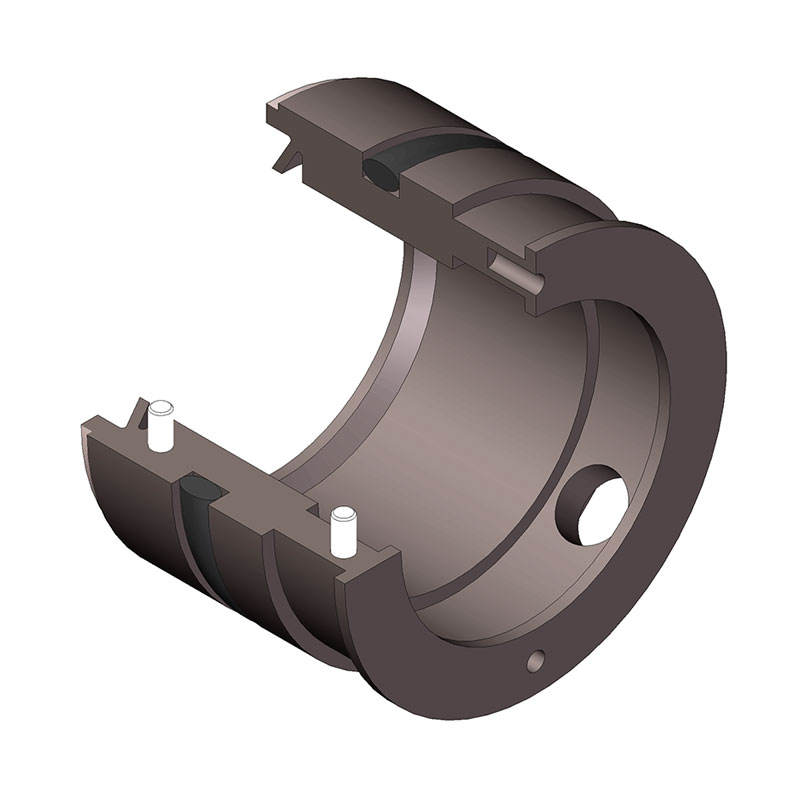

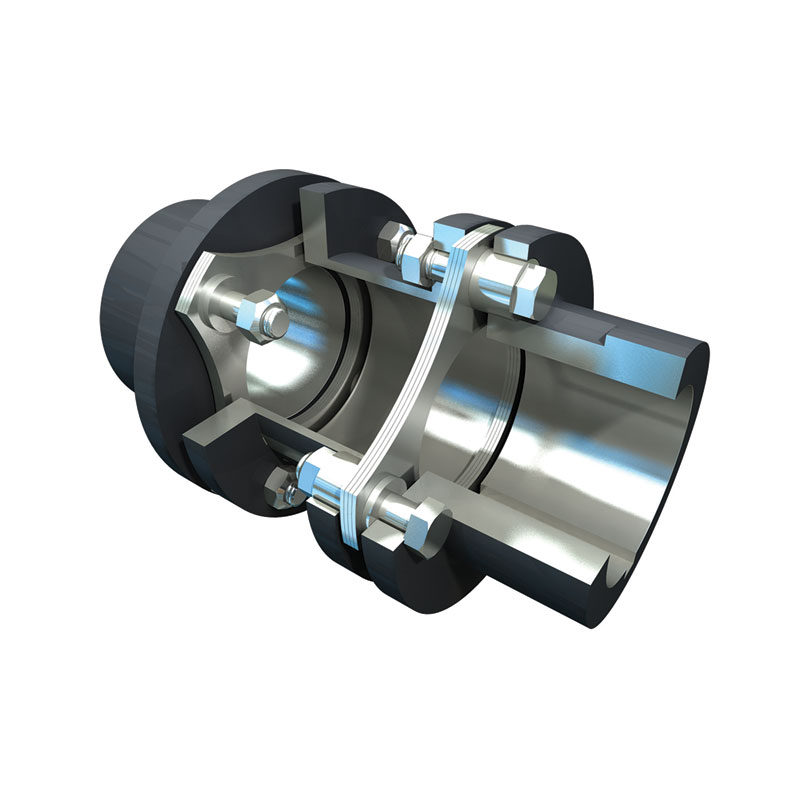

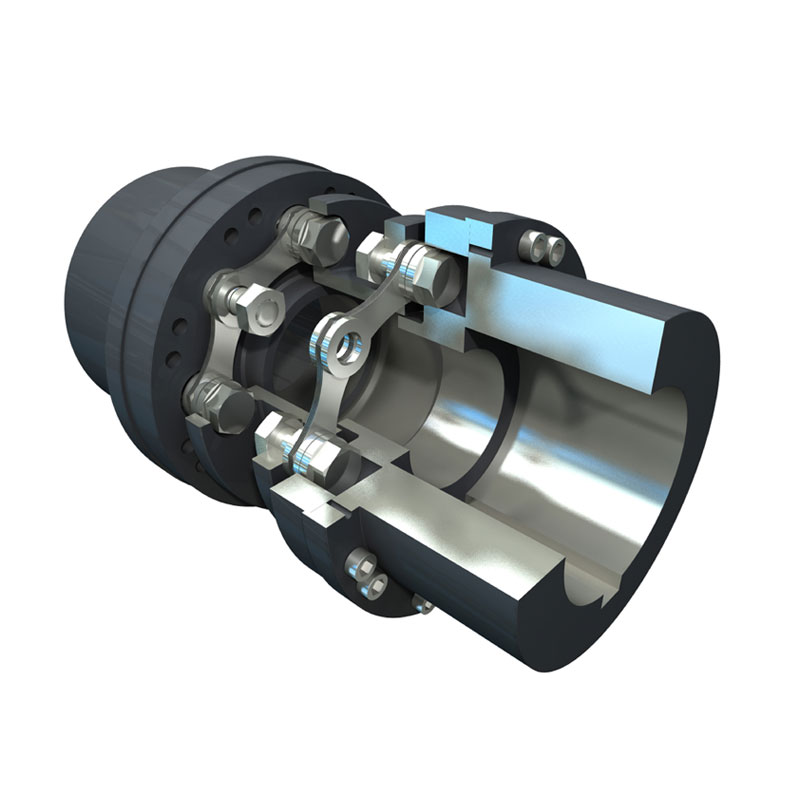

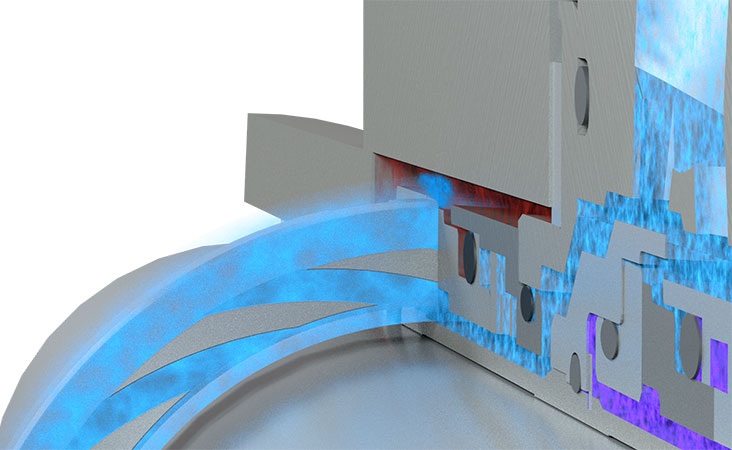

Packing is often preferred by pump OEMs and mine operators. Upgrading to mechanical seals can meet the economic and environmental issues mine operators face. Designed for harsh environments, the advanced materials and robust components of mechanical seals are constructed to help lower maintenance costs and improve pump mean time between repair while reducing water and energy consumption. These benefits can be extended through the addition of seal face technologies such as Upstream Pumping or John Crane Diamond®.

Recommended for You

Extraction

SELECT AN ANSWER TO VIEW PRODUCT MATCH

Magnum-D V8

Magnum-P V7

Magnum-P V6S

TDK/TSK/TLK

A Series

Backflush Filters

High Capacity Filters

Inline Filters

Milling/Grinding

SELECT AN ANSWER TO VIEW PRODUCT MATCH

TDK/TSK/TLK

A Series

Type 5840

Type 5860

K1730/K1761/K1771

C1065/C1070

1345/1349

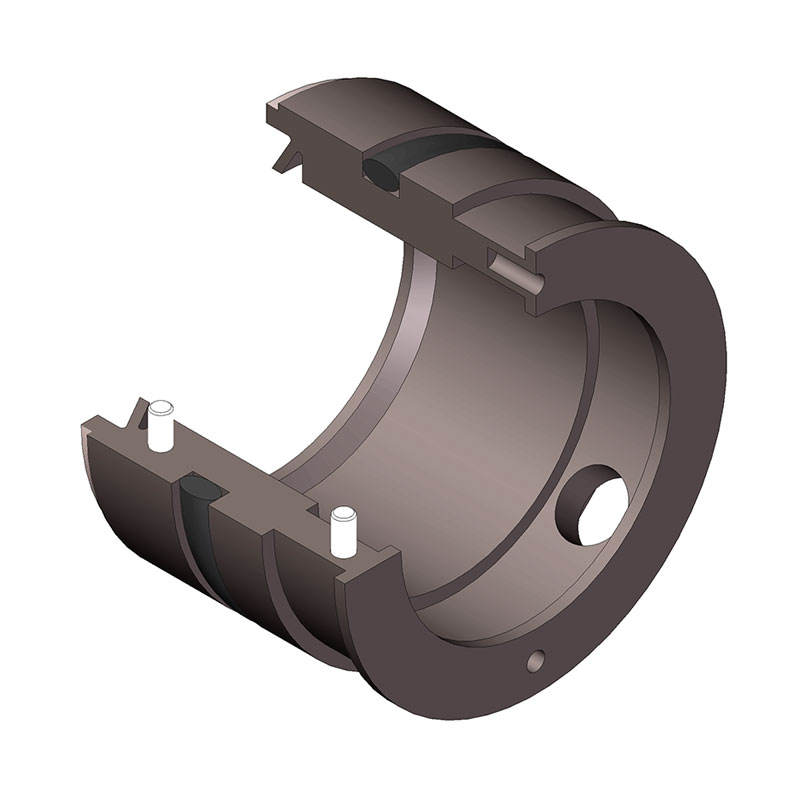

CPR Bushing

Separation

SELECT AN ANSWER TO VIEW PRODUCT MATCH

K1730/K1761/K1771

C1065/C1070

1345/1349

CPR Bushing

Type SB1

Type SB1A

Type SB2/Type SB2A

Type SBW

Type 109

Type 5840

Type 5860

Type 5870

Type 586

Type 3740

Type 37FS

Diamond Seal Face Technology

Upstream Pumping

Type 32

Type 32D

Type 7700

Type CK 728 (W, D, G, GD)

Type CK 738 (W, D, G, GD)

Refining

SELECT AN ANSWER TO VIEW PRODUCT MATCH

L Series

TDK/TSK/TLK

A Series

K1730/K1761/K1771

C1065/C1070

1345/1349

CPR Bushing

Type SB1

Type SB1A

Type SBW

Type 5610/5610Q/5610L

Type 5610D/5620D

Type 5610V/VQ/VP

Type 5620/5620P

Type 5840

Type 5860

Type 5870

Diamond Seal Face Technology

Upstream Pumping

Dewatering

SELECT AN ANSWER TO VIEW PRODUCT MATCH

K1730/K1761/K1771

C1065/C1070

1345/1349

CPR Bushing

L Series

TDK/TSK/TLK

A Series

Type 1

Type 2

Type 21

Type 5840

Type 5860

Diamond Seal Face Technology

Upstream Pumping

Solutions for Every Step of the Mining Process

Extraction

Milling/Grinding

Separation

Refining

Dewatering

Why John Crane?

John Crane is more than just one of the world's leading providers of engineered technology. Our outstanding reputation for designing and engineering high-quality, durable and customized solutions is globally recognized. We partner with our customers and help them meet the latest environmental and performance standards to keep their operations safe and controlled.

In more than 100 years of operation, we have built a strong relationship with dozens of leading mining organizations, providing us with an understanding of the operating conditions within a mine.

Global team of sealing technology experts dedicated to the mining industry:

- Engineers

- Technicians

- Hands-on expertise

- Problem-solving

- Troubleshooting

- Root cause analysis

Mining and Minerals Industry Services

John Crane services can help extend the life of mining and mineral applications and increase production by limiting unplanned downtime and identifying opportunities for improvement:

Maintenance and Repair Services

John Crane’s Maintenance and Repair Services assists with critical systems checks and plant equipment maintenance as well as repair, removal and reinstallation services.

Learn moreMechanical Seals Reliability Programs

John Crane’s Mechanical Seals Reliability Programs assess equipment reliability and performance, analyze root cause failures and recommend strategies for improvement.

Learn moreAsset Management Solutions

John Crane’s Asset Management software offers customers a holistic view of their current systems to help spot unleveraged opportunities.

Learn moreProduct Training

John Crane provides a wide range of training courses that cover the correct procedures for installing, operating and maintaining equipment components.

Learn more