In today's evolving energy landscape, downstream oil and gas companies face the challenge of balancing numerous complex forces — all the while navigating the intricacies of the new energy transition. By definition, downstream refers to the final stages of the oil and gas value chain. It encompasses the refining of crude oil and processing of natural gas into finished products, such as petroleum, diesel, jet fuel, pharmaceuticals, lubricants and petrochemicals. These refined goods are then distributed to consumers through retail and commercial channels.

To better understand the oil and gas industry, it's essential to differentiate the three primary sectors in addition to downstream: upstream and midstream. Upstream focuses on the exploration and production of crude oil and natural gas reserves. Midstream operations involve the transportation, storage, and wholesale marketing of crude oil, natural gas, and refined products.

Some downstream leaders are evolving business models to prioritise low-carbon alternatives such as hydrogen and biofuels. Others are focused on enhancing operational efficiency to offset capital expenditures. No matter the downstream initiative, John Crane’s solutions are engineered to deliver reliability and sustainability.

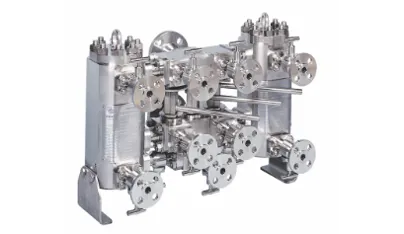

John Crane’s downstream portfolio includes a comprehensive range of mechanical seals and support systems, couplings and filtration solutions. Designed with reliability and sustainability at the core, these innovations meet the demands of pumps, compressors and turbines across the downstream value chain.