What is Liquid Natural Gas (LNG)?

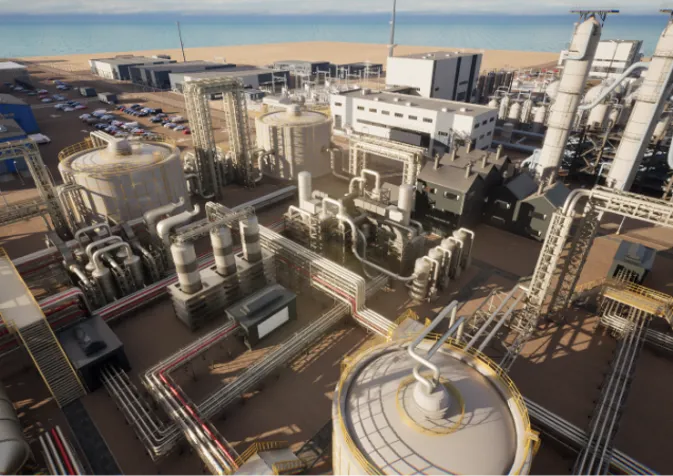

Liquid Natural Gas (LNG) is a natural gas that has been cooled to approximately -161°C (-259°F) to convert into a liquid state. This process reduces its volume by about 600 times, making it easier to store and transport over long distances in specialised LNG carriers, including tankers and ships. These vessels play a crucial role in the supply chain, ensuring safe and efficient delivery from production facilities to key terminals and the global market. Additionally, specialised gas carriers are designed to maintain LNG at cryogenic temperatures during transit.

LNG is a versatile energy source used for power generation, heating, and as a fuel for industrial applications and transportation. It's also one of the cleanest natural gases, producing 40% less carbon dioxide than coal and 30% less than oil. Industries such as shipping and heavy manufacturing rely on it for cleaner and more efficient energy solutions.

Driving the Energy Transition

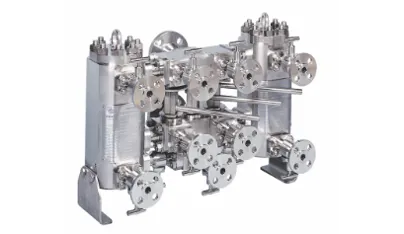

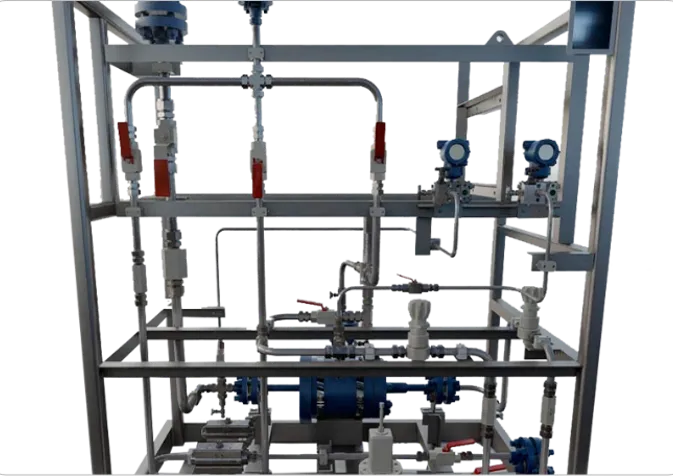

Globally, the demand for liquid natural gas (LNG) is increasing rapidly. As a crucial bridge fuel, LNG has the potential to reduce CO2 emissions while supporting large-scale hydrogen production. Since 1991, when John Crane first provided a dry gas seal for this application, we have been at the forefront of the industry. Today, many of the world’s largest LNG production sites are John Crane dry gas seal customers — and we’re continuing to innovate. We are investing heavily in next-generation solutions to enhance reliability across the LNG value chain, today and in the future.

To fully capitalise on LNG’s potential during the energy transition, rotating equipment must be designed to meet the complex dynamics of natural gas. LNG facilities operate around the clock, so maintaining uninterrupted performance is crucial to maximise output. Any downtime can lead to substantial financial losses and increased gas costs for end users. Additionally, increasing capacity often necessitates larger turbomachinery equipment with unique requirements. John Crane leverages decades of specialised LNG experience to deliver market-ready seal face technologies, filtration solutions, couplings and digital innovations that strengthen the value chain.