What is a Compressor Mechanical Seal?

Part 3: Exploring the World of Compressor Mechanical Seals: A Comprehensive Guide

July 31, 2025

4 Minute Read

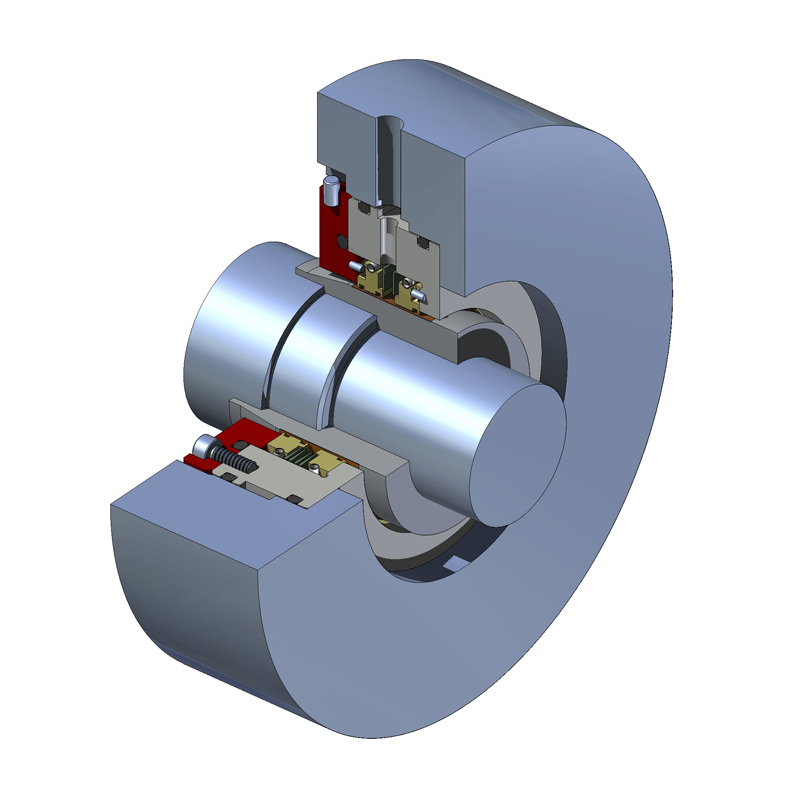

The efficiency and longevity of rotating equipment are critical in industrial systems. A vital component that plays a significant role in achieving these goals is the compressor mechanical seal. As its name suggests, this is engineered to seal gases within rotating equipment, such as pumps and compressors, effectively reducing leakage into the environment. Comprising a stationary and a moving part, compressor mechanical seals are designed to maintain their sealing integrity both during operation and when at rest.

Types of Compressor Mechanical Seals

When it comes to compressor seals, one size does not fit all. Different applications require different types of seals, each with unique features and benefits:

- Wet Seals: Although their use has declined, wet seals serve as a traditional method for sealing compressors. They rely on a liquid film to prevent gas from escaping and necessitate constant fluid management.

- Dry Gas Seals: The advent of dry gas seals has set a new standard in the compressor seal industry. These seals use a gas barrier to achieve sealing efficiency. Recognised for their reliability and operational efficiency, dry gas seals are the epitome of modern compressor mechanical seal technology.

- Separation Seals: Designed to keep bearing oil and the sealing mechanism separate, separation seals are crucial for preventing contamination and preserving the integrity of dry gas seals.

Advantages of Dry Gas Compressor Seals

Choosing dry gas seals for compressors brings numerous benefits:

- Reduced Leakage and Power Loss: These seals are designed for minimal leakage, resulting in lower power consumption and operational costs.

- Increased Reliability: The durability of dry gas seals means less frequent failures and more consistent operation.

- Safety Enhancement: By significantly reducing leakage, they also lower the risk of hazardous exposures, making the workplace safer.

- Ease of Maintenance: Dry gas seals are simpler to maintain than other sealing solutions, which saves cost and time.

- Longer Mean Time Between Repairs (MTBR): The reliability of dry gas seals leads to extended periods between maintenance or repair needs.

Industries Benefiting from Compressor Mechanical Seals

Compressor mechanical seals are indispensable across a variety of industries, ensuring the reliability and safety of numerous processes. Here are some sectors that benefit from the use of these seals:

- Chemical: Compressor seals help prevent leaks of hazardous or corrosive chemicals, ensuring process integrity, worker safety and environmental protection.

- Petrochemical: Compressor seals in petrochemical applications can reduce leaks, ensuring safe and efficient processing of volatile hydrocarbons, enhancing operational safety and reducing environmental impact.

- Power Generation: Compressor seals help maintain process efficiency and prevent the escape of potentially harmful gases in renewable energy applications, such as biofuel production or geothermal power plants.

- Oil and Gas: Compressor seals minimise leaks of oil and gas and byproducts, which is crucial for operational safety, efficiency and environmental compliance.

Success Story: Demonstrating the Impact of Compressor Mechanical Seals

The real-world effectiveness and value of mechanical compressor seals become evident through success stories. These seals enhance operational efficiency and reliability and contribute to significant cost savings and environmental benefits. Here are a few examples:

- An offshore oil and gas platform in Malaysia significantly improved operational efficiency through John Crane's refurbishment program for Type 28XP dry gas seals. This achieved an MTBR of over 20,000 hours and ensured seals were restored to as-new condition at regular intervals.

- An oil refinery in Indonesia utilised John Crane's Type 28AT dry gas seal along with a Type 83 separation seal to eliminate oil lubrication needs and leakage issues, which (combined) previously amounted to several hundreds of litres daily. This innovation resulted in the refinery saving over $600,000 annually in oil replacement costs.

Sustainability: The Forefront of Compressor Mechanical Seal Design

The emphasis on sustainability is paramount in the current industrial landscape, particularly as industries transition toward New Energy. Compressor mechanical seal solutions can be tailored to meet specific American Petroleum Institute (API) regulations, ensuring adherence to stringent quality and safety standards.

Compared to alternatives like carbon rings, mechanical seals - particularly dry gas seals - offer superior sustainability. They boast longer lifespans, lower leakage rates and energy efficiency, contributing to more sustainable industrial processes.

Safety Considerations

Optimised compressor mechanical seal solutions are available for almost all types of liquids and gases, including those requiring the utmost cleanliness or handling highly toxic substances. These solutions ensure safe application in a broad spectrum of industries.

Compressor Mechanical Seal Experts

As experts in dry gas seal technology, we at John Crane play a pivotal role in enhancing the efficiency, reliability and safety of rotating equipment machinery. Our advancements in compressor mechanical seals are crucial for reducing environmental impact, improving operational safety and complying with regulatory standards. Leverage our expertise in dry gas seal technology to elevate your rotating equipment's performance.

We provide engineering expertise, technical support and a global service network to help customers select and maintain the right sealing solutions for their specific applications. Our team collaborates with operators to address performance challenges, extend equipment life and minimise unplanned downtime. John Crane Sense® also enables operators to track seal performance in real-time, helping them to address issues proactively.

To explore how our sealing solutions can support your operation, get a quote or contact us to speak with a technical specialist.

Learn more about compressor mechanical seals in our educational blog series: Part 1, Part 2, with Parts 4a and 4b coming soon.