What is a Mechanical Seal?

Part 1: An Overview and Origins

July 30, 2025

4 Minute Read

A mechanical seal is used in rotating equipment, such as pumps and compressors, to prevent process leakage from entering the environment and avert contaminants from entering the process being pumped. A mechanical seal consists of two main parts: a stationary element fixed to the equipment and a rotating component moving with the shaft. To see how these components interact in practice, view our comprehensive animation, which illustrates each part of the seal and how they work together.

Early designs of pumps used packing in their stuffing boxes to seal the shaft and prevent the process from escaping. One of the earliest mechanical seal designs from the 1900s was used for refrigeration compressors, but later, the technology was applied to centrifugal pumps and compressors.

Maintenance engineer John Crane entered the story in 1910. He began repairing leaky radiator feed pumps using lead foil from tobacco packages and earned his first of three packing patents. This is how the metallic packing industry was born.

Over the next several decades, the company that would eventually bear the name John Crane would continue developing new packing options and eventually manufacture originally designed and patented mechanical seals.

Types of Mechanical Seals

Over the years, new materials and designs have appeared and evolved. As a result, the capabilities of the mechanical seal and the range of industrial applications have also increased. Seals now come in various configurations, such as single, double and tandem, and operate in either dry or wet processes.

In many industries, including oil and gas, API standards are applied to certify mechanical seals used for specific applications. For example, API 682 ensures that seals meet the rigorous demands of critical processes, such as those found in refineries and pipelines, to guarantee reliability and safety.

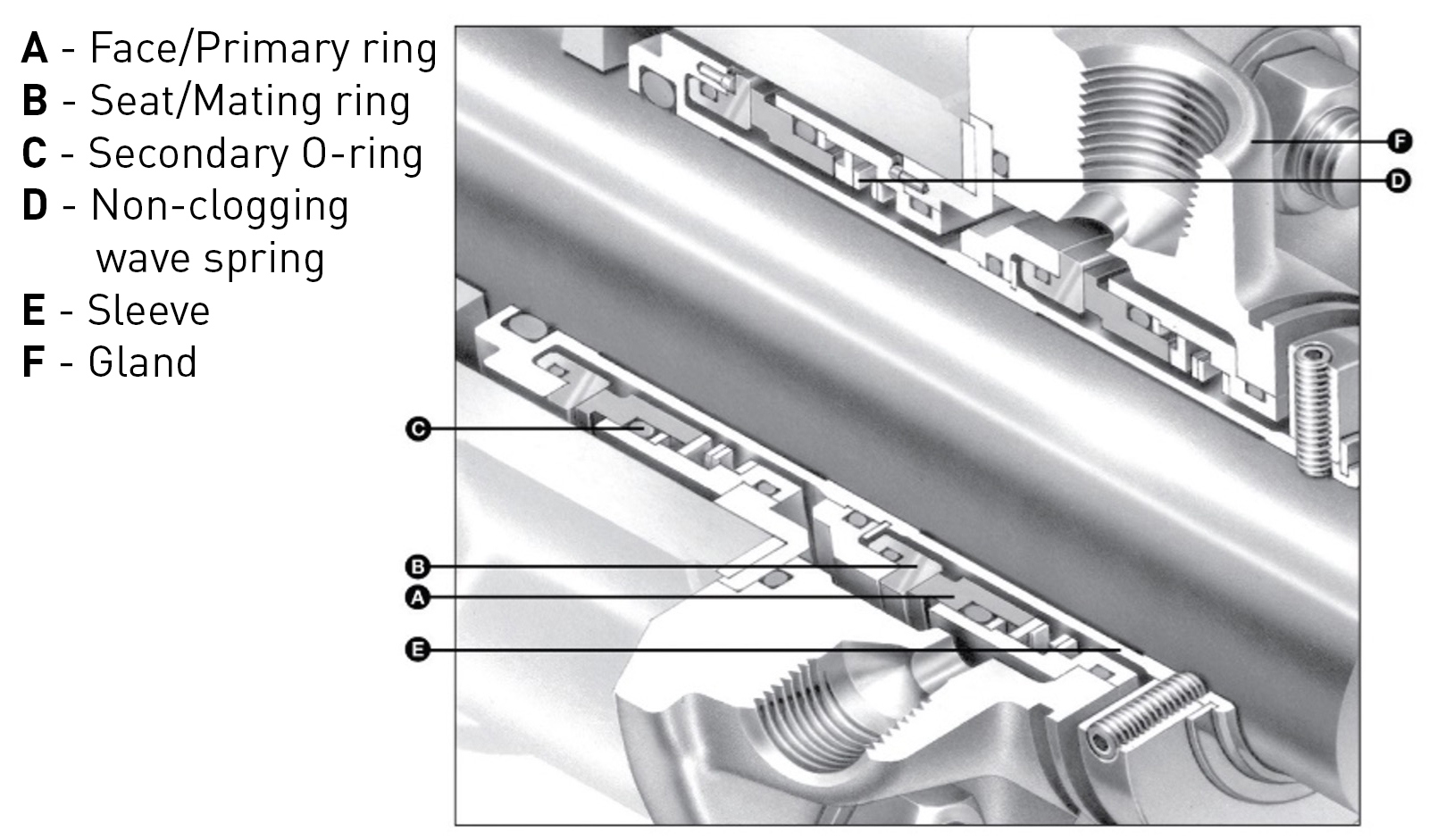

Wet Seals

Wet seals are liquid-lubricated mechanical seals commonly used in pumps and other types of rotating equipment, such as vessels and agitators.

Wet seals are widely employed in oil and gas, chemical, pharmaceutical, pulp and paper, power, water and wastewater, and mining industries. They are suitable for a broad range of applications involving both toxic and non-toxic products and can be applied to all types and sizes of industrial equipment.

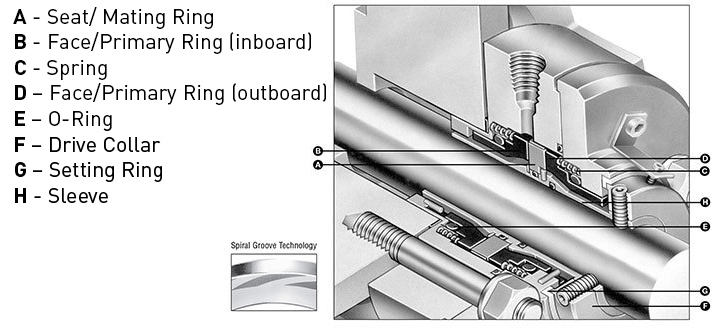

Dry Gas Seals

Dry gas seals (DGS) use a thin film of gas to separate the seal faces. They are typically installed in centrifugal compressors for the following applications:

- Liquefied natural gas (LNG) plants

- Oil refineries

- Process plants

- Chemical plants

- Natural gas pipelines and pipeline distribution

The main advantage of using a DGS in a centrifugal compressor is its ability to reduce process gas leakage and contamination compared to older technologies such as oil seals. It also enables more reliable and long-lasting operations and is applicable to pumps, mixers, agitators and reactors.

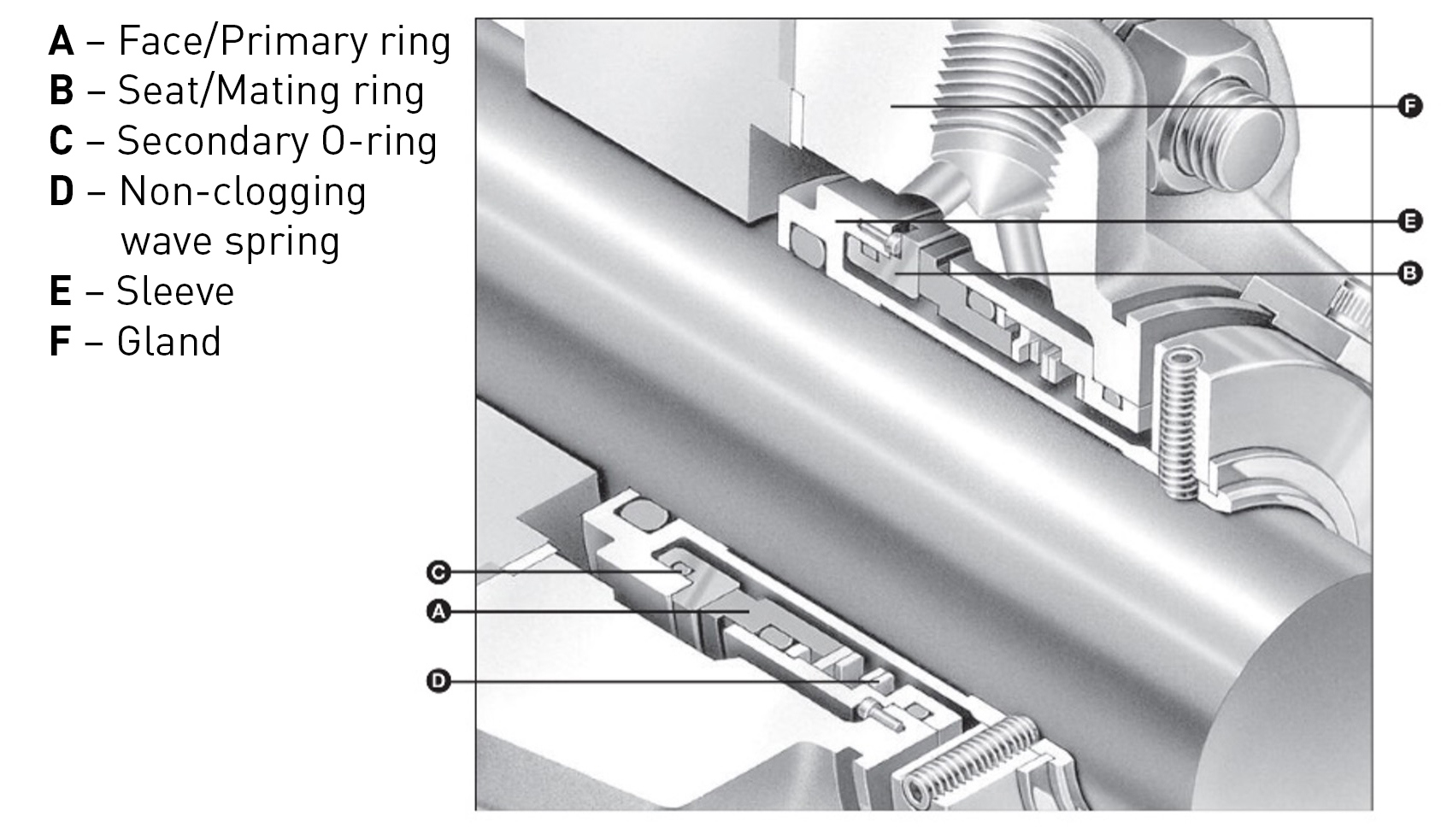

Mechanical Seal Arrangements

Mechanical seal arrangements are categorised according to the number of seals:

- Single mechanical seal

- Dual mechanical seal, which can either be pressurised or unpressurised

All mechanical seals require lubrication of the faces for proper operation. The mass flow of liquid across these faces is an essential component of the seal design, but depending on the fluid used as the face lubricant, it can also result in leakage management concerns.

In single mechanical seals, the process fluid is typically the face lubricant. Dual mechanical seals rely on an extended supply of buffer (low pressure compared to process) or barrier (high pressure compared with process) fluid to control pressure at the seal and to provide cooling and lubrication to one or both sets of seal faces in the arrangement.

Sealed fluid volatility dictates whether detectable leakage is acceptable (single seal) or must be contained (dual unpressurised) or completely isolated from the atmosphere (dual pressurised). Proper seal arrangement selection requires coordination between the seal supplier and equipment user to meet safety, reliability and environmental objectives.

Recommended Resources

For those looking to deepen their understanding of mechanical seals, we suggest exploring the following resources:

- Case Study: Mechanical Seal Solution Enables Renewable Hydrogen and Oxygen Production for Industrial and Transportation Applications

- Blog: CO2 Transportation: Sealing Solutions for Tomorrow's CCUS Infrastructure

- Whitepaper: Carbon LF™: A New Material for Tough LNG Conditions

- Blog: The Significance of Seal Retrofits on Emissions & Energy Efficiency

Mechanical Seal Experts

We hope this overview gives you a clearer understanding of the history, purpose, types and arrangements of mechanical seals. In upcoming educational pieces, we will explore mechanical seals in operations such as compressor seals, pump seals, and vessel and agitator seals.

To further your knowledge, we will also provide expert insights and resources on topics like couplings, packing and other essential components. Visit our blog section for more articles in this educational series.

When it comes to keeping your rotating equipment running 24/7, John Crane's comprehensive range of mechanical seals and systems has you covered. Our products are designed to optimise reliability, enhance performance and reduce operating costs. Whether you need robust solutions for high-pressure environments, advanced dry gas seal technology or tailored sealing systems, John Crane is here to help.

Get a quote or contact us to connect with our experts and find the right solutions for your operations.

Explore more insights in our educational blog series. Parts 2, 3, 4a, and 4b coming soon.