What Is A Pump Seal?

Part 2: Unlocking the Secrets of Pump Mechanical Seals: A Comprehensive Guide

July 31, 2025

4 Minute Read

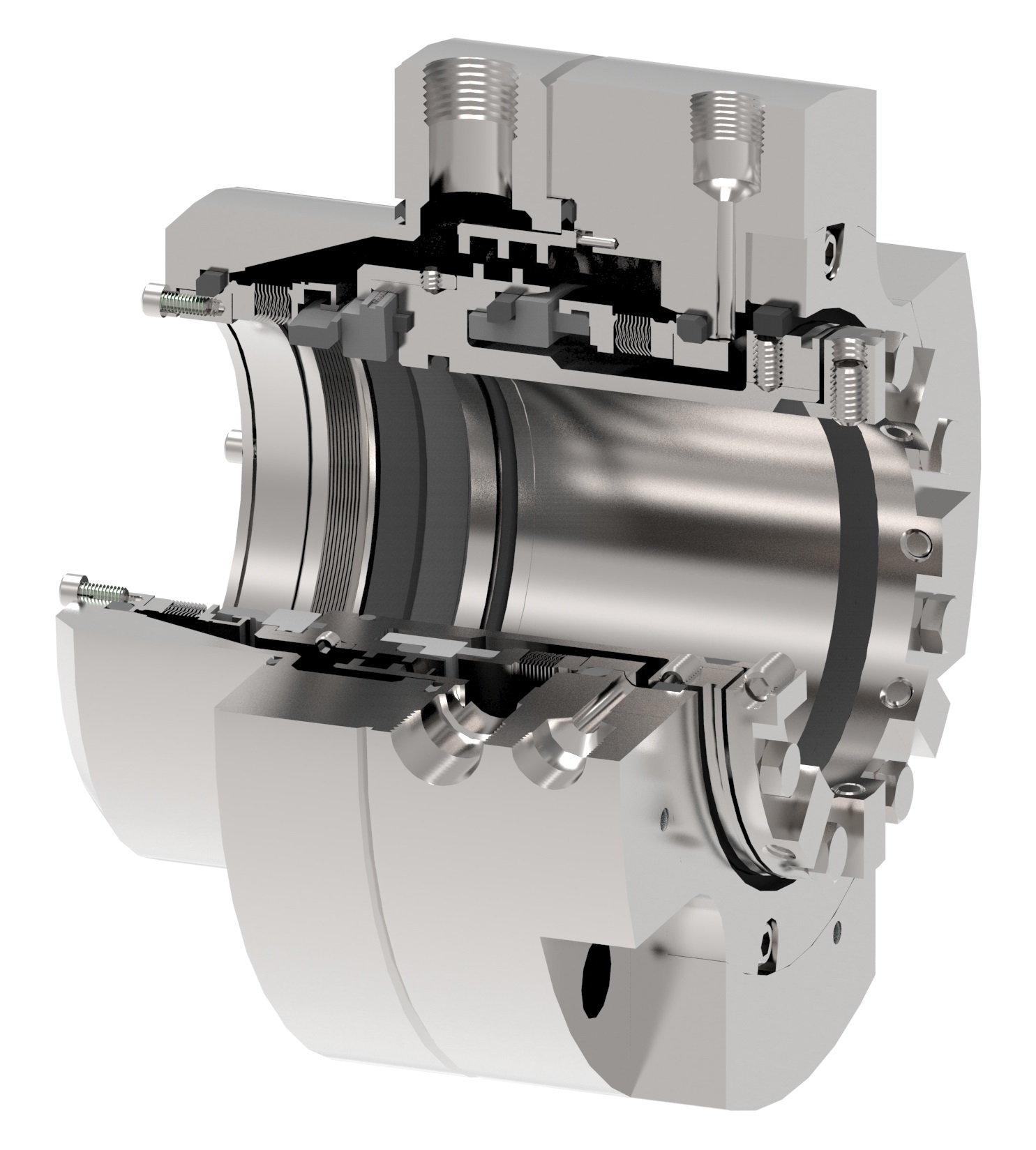

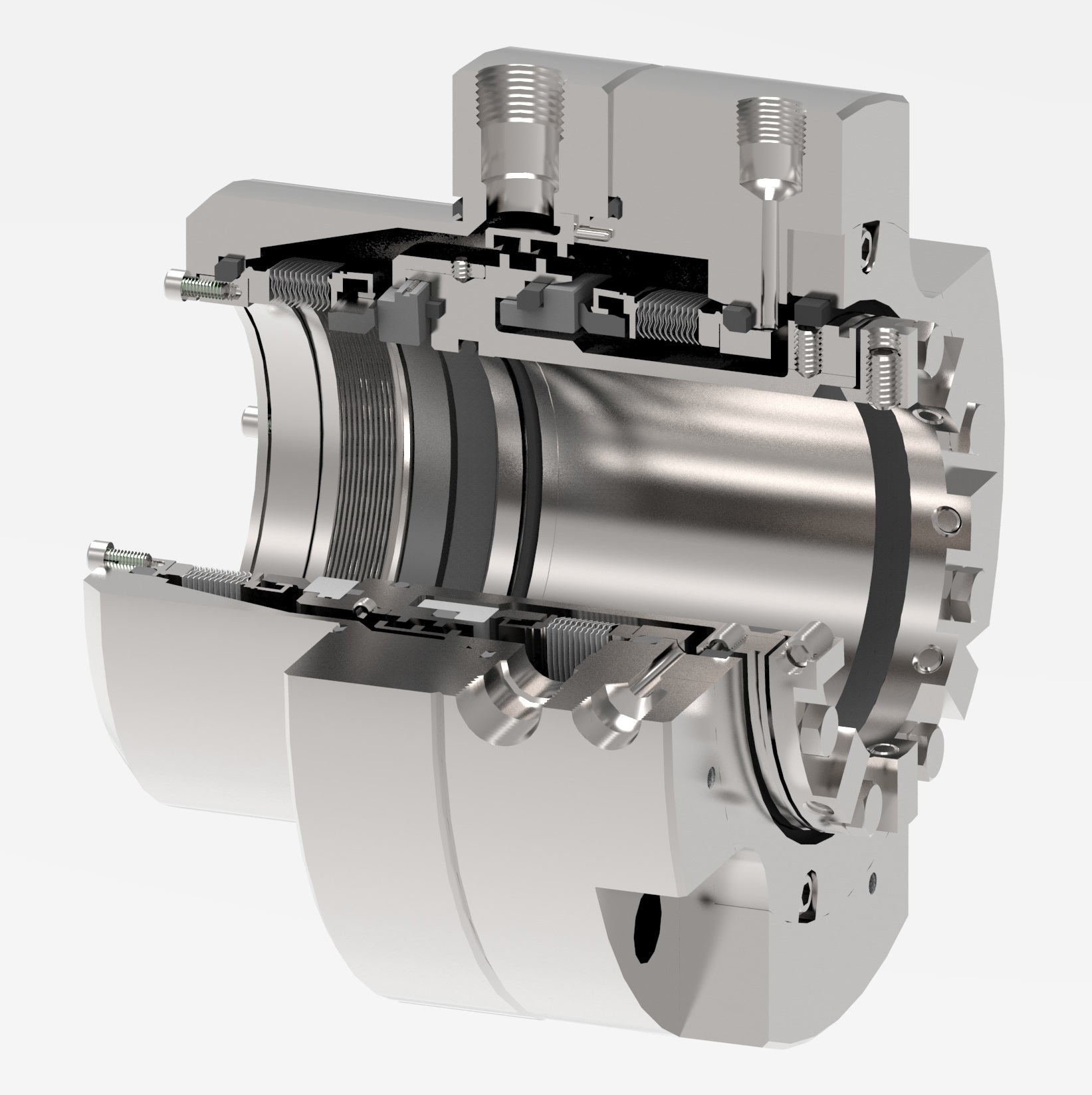

Mechanical pump seals are at the heart of modern industrial processes, playing a critical role in ensuring the pumps operate efficiently and minimising leakage. By preventing fluid from leaking along the shaft and out of the pump casing, these seals protect the environment and equipment. They are typically found in centrifugal pumps, situated where the pump shaft enters the pump casing.

A mechanical pump seal consists of several essential parts: a stationary seal face that includes a gland and sleeve mounted on the shaft. It also has a rotating face mounted on the shaft, but with the assistance of the sleeve. Springs are another vital component, facilitating the necessary pressure for sealing.

The materials used for the seal faces vary depending on the application, including carbon, silicon carbide and tungsten carbide. Carbon is favoured for its chemical, non-contaminating properties, especially with water or water-based fluids. The metallic parts are commonly made of stainless steel or duplex, with super duplex, titanium, and Hastelloy used depending on the chemical activity involved.

What Are The Different Pump Seal Types?

Pump seals are diversified to meet various operational requirements and applications:

- Single Seal: This is the standard design used for general applications.

- Double Seal: Preferred for handling chemical and other complex fluids, providing an additional layer of protection and reliability.

- Split Seal: Designed for easy installation without dismantling the machinery and ideal for large equipment.

- Tandem Seal: Offers an extra level of security, with two seals working to ensure operational integrity.

What Are The Benefits of Implementing Pump Mechanical Seals?

Each type of mechanical pump seal offers many advantages that extend beyond simple operational improvements. By dramatically minimising fluid leakage, they play a pivotal role in mitigating the risk of fluid contamination. This leads to enhanced operational efficiency, reduced maintenance costs and extended equipment lifespan.

Also, these seals are crucial in reducing water consumption and preserving natural resources. Their use in sealing systems supports global efforts to make industrial processes more sustainable and, following the American Petroleum Institute's API 682 standards, demonstrates an organisation's commitment to protecting the environment.

What Are The Different Applications of Mechanical Pump Seals?

Mechanical seals are commonly found in a wide range of rotating equipment and machinery, especially in pumps and compressors. They find applications across a variety of industries, including oil and gas, and mining, where the reliability and efficiency of fluid handling are paramount.

Success Stories: Demonstrating the Impact of Mechanical Pump Seals

The real-world impact of mechanical pump seals can be best appreciated through tangible success stories across various industries. These seals enhance the reliability and efficiency of equipment and significantly reduce operational costs and environmental impact.

-

Oil and Gas

In the demanding environments of the oil and gas industry, pump seals can reduce downtime and maintenance costs by improving the reliability of pumps that manage volatile and corrosive fluids. Their robust design and material composition make them indispensable for operations that cannot afford unexpected failures or leaks.

-

Mining

Pump seals in the mining industry are crucial for the safe and efficient transport of slurry and other abrasive materials. Their durability and resistance to extreme conditions prevent leaks and contamination, ensuring continuous operation and safety in harsh mining environments. Mechanical seals are also constructed to help lower maintenance costs and improve pump mean time between repair, while reducing water and energy consumption.

-

Case Highlight: A Plywood Manufacturing Facility's Success

A compelling example of mechanical seal effectiveness is seen in a plywood manufacturing facility in the U.S. The facility significantly upgraded to John Crane Diamond® cartridge seals for its hot water applications. This transition improved reliability and seal life span, showcasing how advanced seal face technologies can generate substantial operational advantages in various applications.

Safety Considerations Of Mechanical Pump Seals

Safety is a top priority when it comes to mechanical seals. Compliance with API standards is just the beginning. Certification under the National Sanitation Foundation's NSF 61 is crucial for applications involving drinking and potable water in the U.S., ensuring that the mechanical seals help to reduce contaminants in the water supply.

This certification is rigorously audited to maintain the highest safety and quality standards. Similarly, Europe's Water Regulations Advisory Scheme (WRAS) sets stringent requirements for materials and products used in water supply systems, ensuring they are safe and suitable for use. U.S. Food & Drug Administration (FDA) compliance is also essential for food and beverage applications, where mechanical seal integrity can directly impact product safety and quality.

Qualified staff are also crucial for ensuring proper installation, maintenance, and operation of your pump seals. Skilled personnel help prevent failures, extend seal life and improve system efficiency through regular training and expertise. Learn more about Product Training at John Crane here.

John Crane Are Mechanical Seal Experts You Can Trust

At John Crane, our mechanical seal experts are dedicated to optimising your industrial operations with minimal environmental impact and maximum safety. Our innovative seal face technologies, such as John Crane Diamond, extend the life of mechanical pump seals and boost reliability while lowering operating expenses, and Upstream Pumping focuses on water conservation, further reducing costs and improving pump reliability.

With John Crane, you gain access to dedicated expertise and technology tailored to your needs, ensuring optimal performance and sustainability. Our team of experts is here to assist you in selecting the right seal for your needs. Whether you're interested in single seals for general applications or more specialised solutions like double or split seals, we're here to help. Contact us here or get a detailed quote here.

Learn more about mechanical seals in our educational blog series: Part 1 is available now, with Parts 3, 4a, and 4b coming soon.