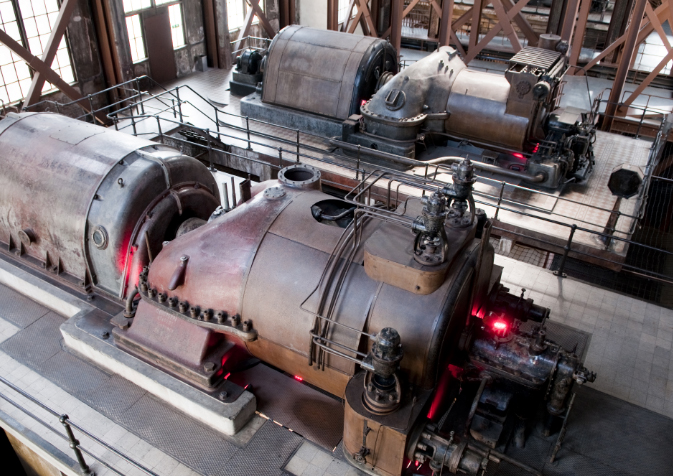

Power generation plants vary greatly across the industry, from those fueled by coal or natural gas to those powered by nuclear, hydroelectric or geothermal energy. But though they operate differently, they still share a common goal: to meet the growing demand for energy in a responsible, efficient way. John Crane’s depth and breadth of applied engineering expertise, product innovation and reliability services help plants of all types increase uptime, reduce emissions and improve efficiency to achieve all of their goals.

We deliver proven mechanical seal technologies and services that improve power plant manufacturing performance through:

- Increased operational reliability

- Improved equipment uptime

- Fewer maintenance interventions

- Reduced seal water usage and energy consumption

- Cost-effective environmental compliance

Recommended for You

Tested Designs, Proven Solutions

For 100 years, John Crane has supported the power generation industry with reliability-tested solutions. Because John Crane mechanical seals operate in mission-critical power generation applications, our seal designs have been carefully tested under simulated in-plant conditions to ensure dependability in demanding situations. Our test centers can also perform chemical analyses and material compatibility evaluations specific to power generation applications.

All John Crane products are manufactured and certified in accordance with the most recent environmental, regulatory and technical standards around the world:

|

|

And our commitment to reliability doesn’t stop at quality components. With 200+ global rapid-response centers, we have one of the most reliable support and repair services in the world.

Power Generation Products

Many John Crane products specifically address the needs of the power generation industry by improving the productivity and performance of mission-critical operations.

Power Generation Industry Services

In addition to our highly engineered products, John Crane also provides a wide range of services designed to optimize overall operations. After assessing existing applications and components, we’ve successfully improved centrifugal compressor efficiency by upgrading mechanical seals to dry gas seals, retrofitting aluminum labyrinths with thermoplastic seals and upgrading bearing designs. Here are some other ways we can help:

Maintenance and Repair Services

John Crane’s Maintenance and Repair Services assists with critical systems checks and plant equipment maintenance as well as repair, removal and reinstallation services.

Learn moreMechanical Seals Reliability Programs

John Crane’s Mechanical Seals Reliability Programs assess equipment reliability and performance, analyze root cause failures and recommend strategies for improvement.

Learn moreAsset Management Solutions

John Crane’s Asset Management software offers customers a holistic view of their current systems to help spot unleveraged opportunities.

Learn moreProduct Training

John Crane provides a wide range of training courses that cover the correct procedures for installing, operating and maintaining equipment components.

Learn morePower Generation Products

Showing 1–38 of 38 products

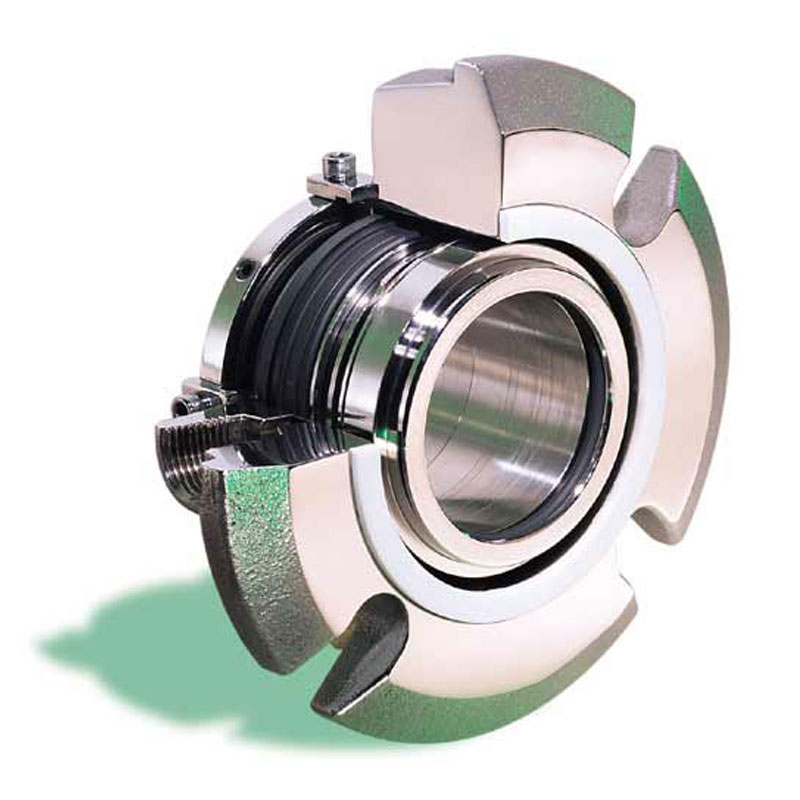

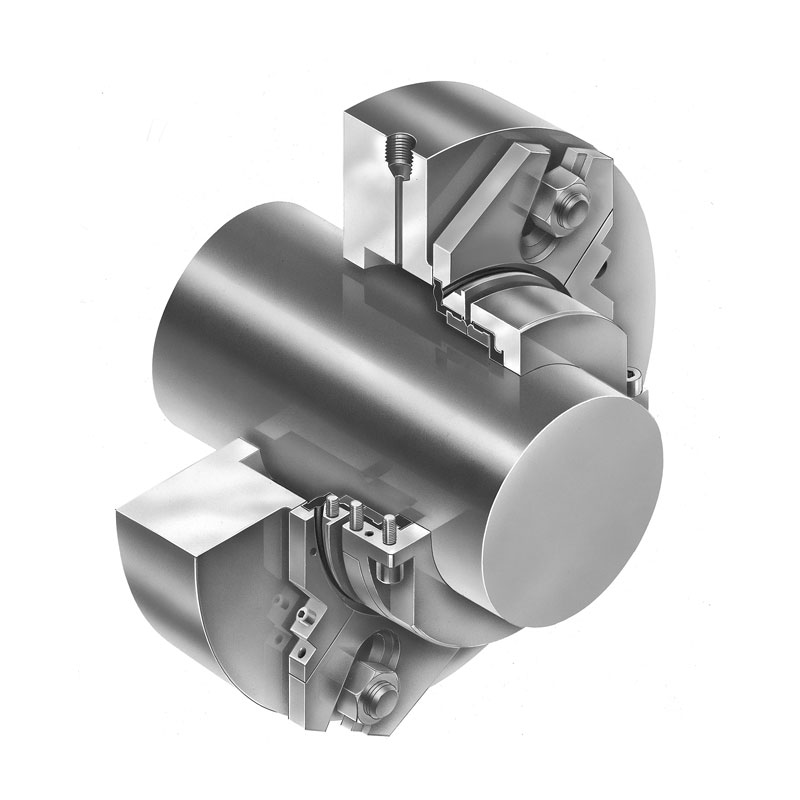

Type 270F

Heavy-duty Cartridge Seal for Boiler Feed Circuit Applications

Suitable for larger equipment, the Type 270F is a boiler feed seal designed for the most demanding performance, and is...

Type 48LP

Low-emission, Low-pressure O-ring Shaft Seal for Light Hydrocarbon Services

Type 48 seals evolved from the successful, proven John Crane Type 8B1 design, the preferred choice for safe, reliable, unpressurized...

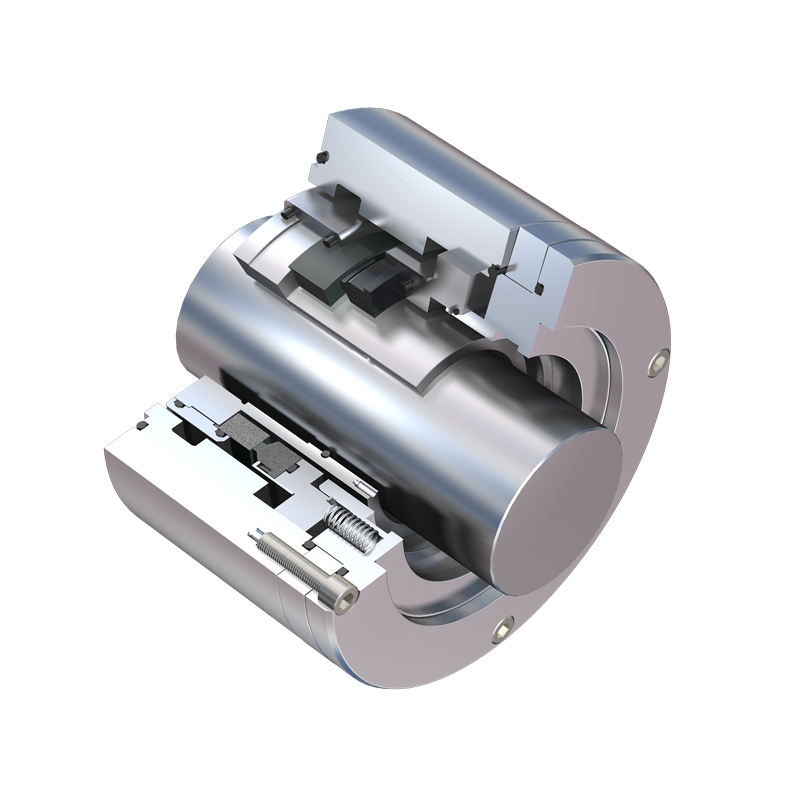

Type 5610/5610Q/5610L

Universal Cartridge Seal Family — Single Cartridge O-Ring Seal

The first truly universal cartridge seal, the Type 5610 will change your approach to sealing. Since the 5600 Series components...

Type 4610

Compact, General-duty, Single Cartridge O-ring Seal

The Type 4610 single cartridge seal, available off-the-shelf the world over, combines affordability with fluid-sealing dependability...

Type 1

Full Convolution Industrial-duty Elastomer Bellows Shaft Seal

With its proven track record of exceptional performance, the Type 1 elastomer bellows seal is widely recognized as the industry's...

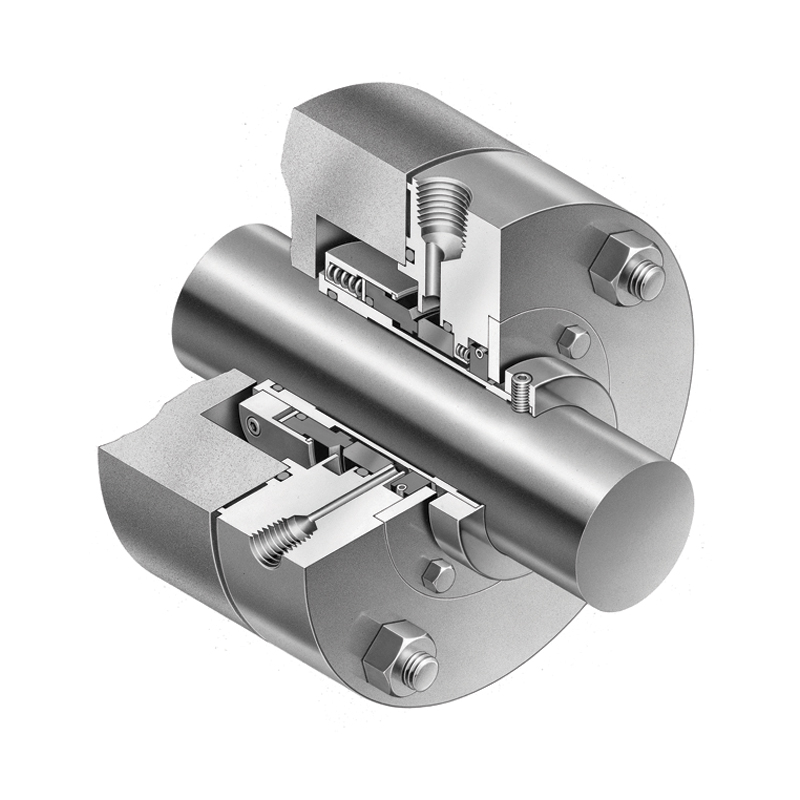

Type 3740

Advanced Design, Wet-running Cartridge O-ring Split Seal

The Type 3740 mechanical seal is a family of split seals using the latest modular split seal technology from John Crane that...

Type 37FS

Heavy-duty Split Elastomer Bellows Seal for Agitators, Mixers and Pumps

The Type 37FS fully split mechanical seal helps significantly reduce maintenance on larger, difficult-to-seal equipment. It is recommended for use on...

Type 5860

Heavy-duty Cartridge Slurry Seal

Available as a single or double seal, the Type 5860 is designed to operate in the harshest abrasive slurry environments....

Type 5870

Flushless Cartridge Seal

The Type 5870 is a single, balanced, O-ring pusher cartridge seal. It is designed to operate unsupported in all...

Type 5840

Cost-effective Cartridge Slurry Seal

Our Type 5840 single-cartridge seal encompasses many of the advantages associated with heavy-duty seal design, encased in a cost-effective...

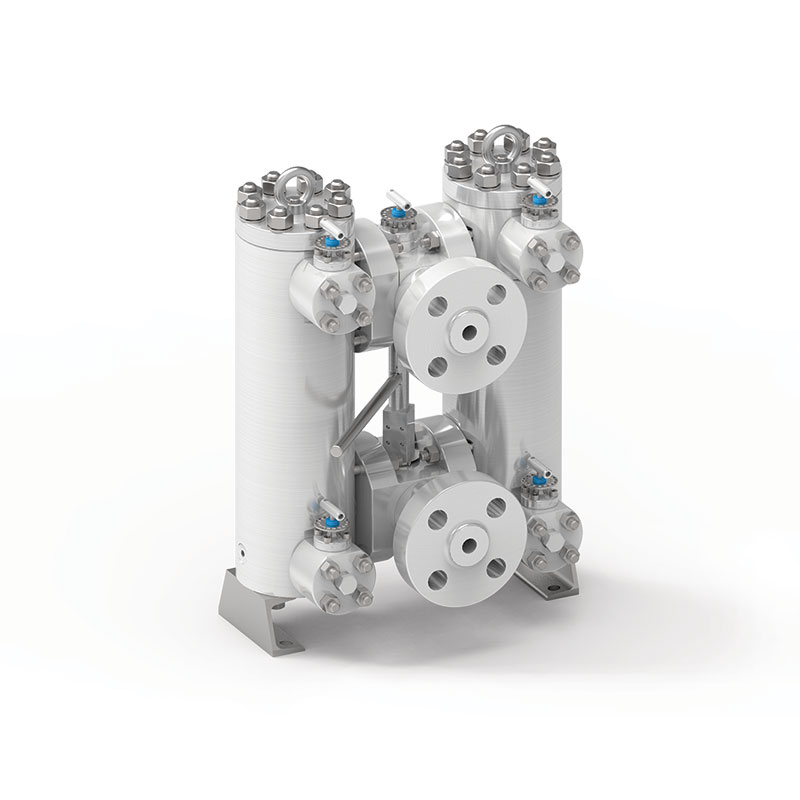

Liquid Filtration

Filtration Solutions for Fluid Applications

John Crane’s Indufil® liquid filters can be applied to almost any liquid application, from hydraulic and bearing oil systems to lubrication and...

Seal Gas Filtration

Optimized Seal Gas Filtration for API 692

Specially designed John Crane’s Indufil® filters remove liquid and particle contamination and maximize reliable dry gas seal operation.

Fuel Gas Filtration

Fuel Gas Conditioning and Heating Equipment

John Crane’s Indufil® fuel gas filtration units are individually tailored to maximize reliability regardless of the condition of the supply gas. They...

Fuel Oil Filtration

Fuel Oil Purification Equipment

John Crane’s Indufil® complete fuel oil filtration systems are fitted as standard to many leading brands of gas turbines. Adequate filtration of...

Double 3-way and 6-way Transfer Valves

Ball Valves for Interlinking Heat Exchanger Equipment

John Crane's Indufil® ball valves are designed in-house and manufactured for use in duplex systems to enable continuous operation while one side...

Filter Elements

John Crane’s Indufil® Replacement Filter Elements

The performance of a filter unit is entirely dependent on the elements fitted, making it essential to fit genuine John Crane’s Indufil® ...

Process Filtration

H-C

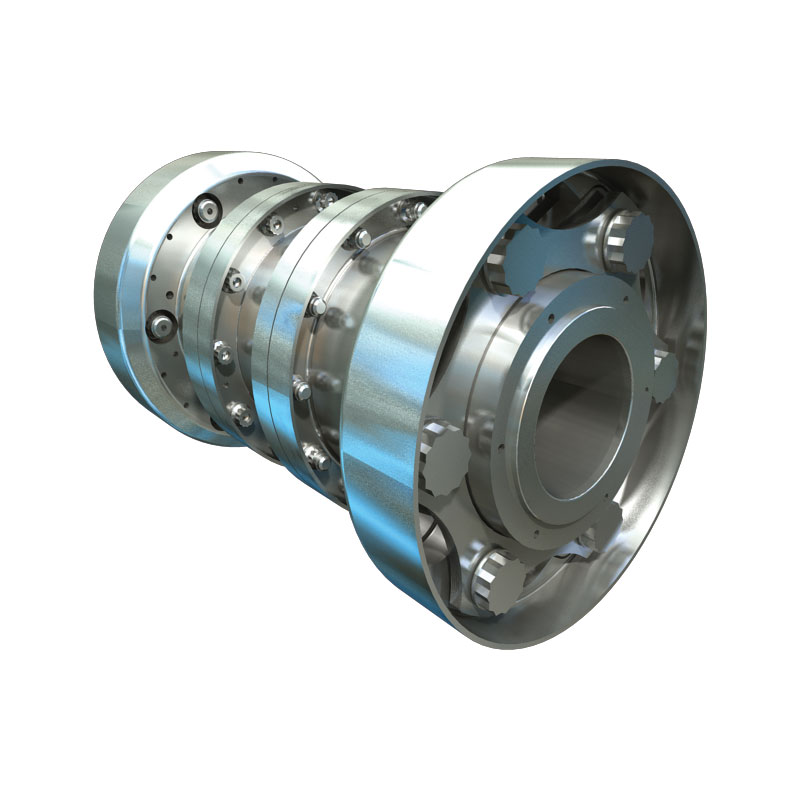

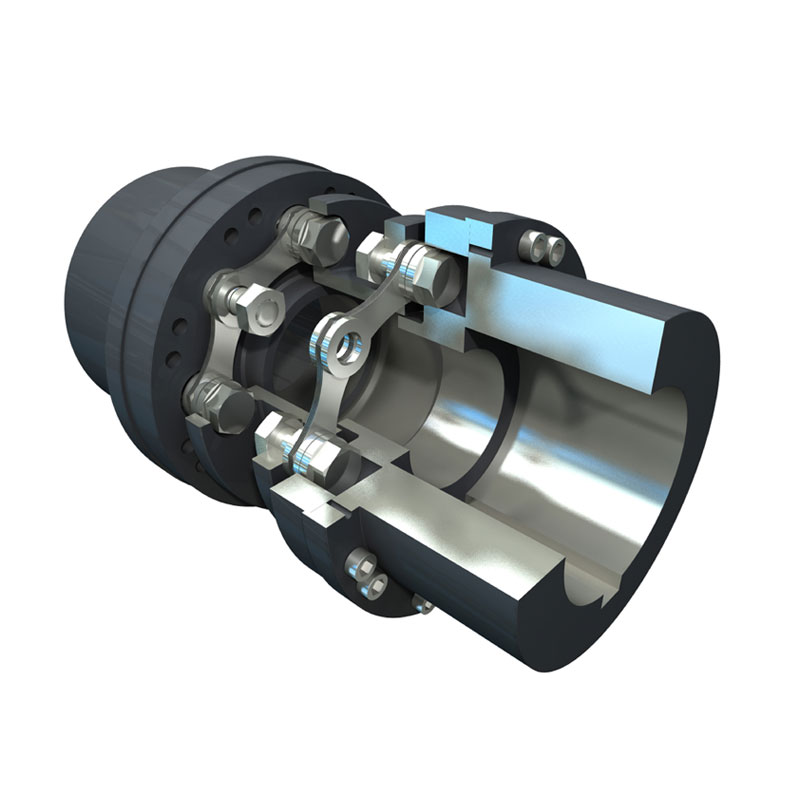

High-performance, Reduced-moment and Low-windage Design (API 671 and ISO 10441)

H-C couplings offer the lowest possible overhung moments and additional shrouding of the flexible elements and bolts. This arrangement...

MHS Series

M Series Multiple Membrane Straight Diaphragm Coupling with Stainless Steel Discs in Pre-assembled Single Diaphragm Packs

With John Crane’s Metastream® MHS Series coupling range, the torque is transmitted through pre-assembled packs with a built-in safety bush...

L Series

General-purpose All-metal Membrane Coupling

L series range of membrane couplings has been specifically designed to provide a cost-effective solution for demanding industrial applications....

A Series Close-coupled Arrangement

Close-coupled Wrap-fit Urethane Element Coupling

John Crane A Series couplings provide a solution to one of the most persistent and troublesome problems facing maintenance personnel: periodic...

TDK/TSK/TLK

T Series Stainless Steel Discs in Pre-assembled Cartridge for Medium to High Torque Applications (Metric)

John Crane’s Metastream TDK/TSK/TLK Series are metallic membrane (disc) couplings, incorporating industry...

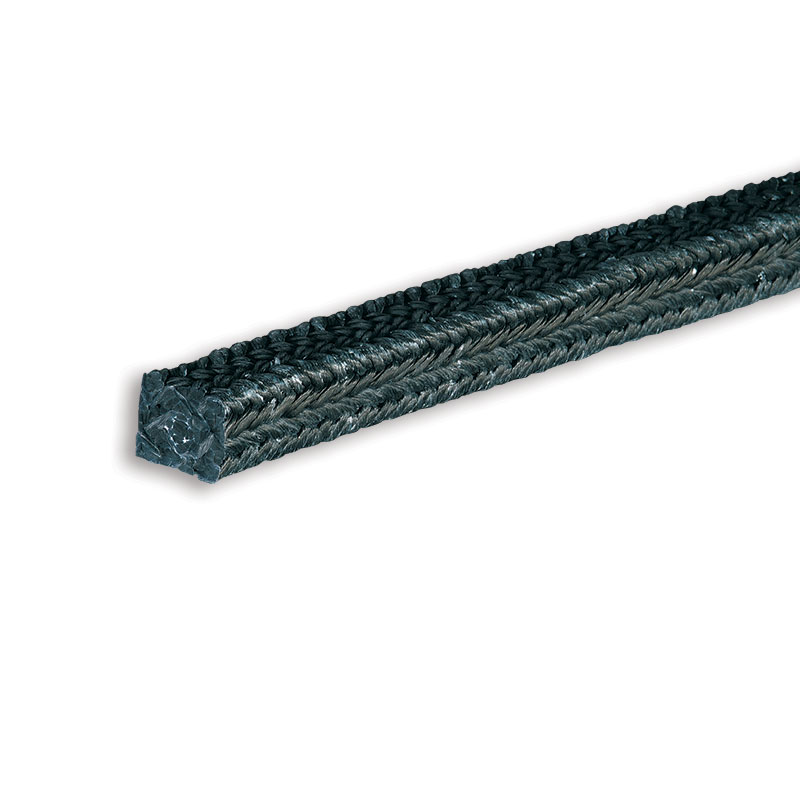

1625G

High-temperature Graphite Braided Packings

John Crane styles 1625G are the ultimate in packing, offering the ability to perform in both...

G57/G58/G58I

Braided Flexible Graphite Packing

G57, G58 and G58I are high-purity, high-strength interlace braided flexible graphite packings designed to handle a wide range of fluids....

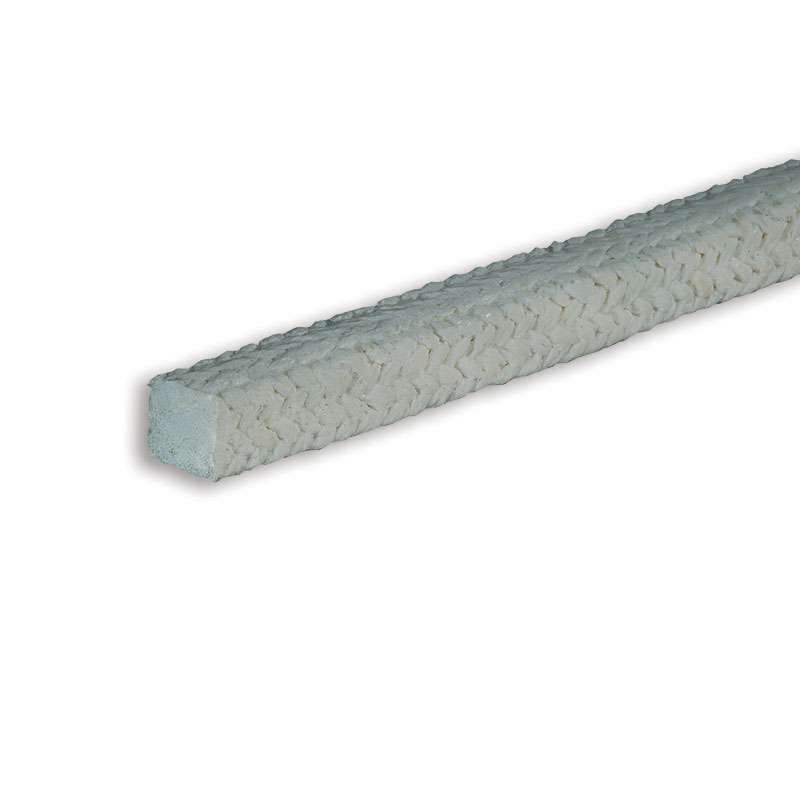

1332/1335

General-service Braided Synthetic Packings

John Crane styles 1332 and 1335 are cost-effective general-service packings constructed of the highest-quality synthetic fibers and lubricants....

894/1340

General-service Braided Graphite Packings

John Crane styles 894 and 1340 are cost-effective graphite general-service packing constructed of the highest-quality synthetic fibers and...

WCH

Water-cooled Heat Exchangers

Water-cooled heat exchangers may be applied where water is readily available. Heat exchangers may be packaged together with seal support...

WCV

Water-cooled Heat Exchangers

Water-cooled heat exchangers may be applied where water is readily available. Heat exchangers may be packaged together with seal support...

K2S

Water-cooled Heat Exchangers

Water-cooled heat exchangers may be applied where water is readily available. Heat exchangers may be packaged together with seal support...

GR1/1C

Reservoirs for Chemical, Pharmaceutical and General Industries

Stainless steel pressure vessels (with or without internal cooling coil) designed for general industry applications. These reservoirs provide buffer/barrier fluid...

GR2/2C

Reservoirs for Chemical, Pharmaceutical and General Industries

Stainless steel pressure vessels (with or without internal cooling coil) designed for general industry applications. These reservoirs provide buffer/barrier fluid...

GR3/3C

Reservoirs for Chemical, Petrochemical, Pharmaceutical and General Industries

Stainless steel pressure vessels (with or without internal cooling coil) designed for general industry applications. These reservoirs provide buffer/barrier fluid...

GP-S/GP-D

Gas Panels for Chemical, Pharmaceutical and General Industries

Non-API gas control panel to filter, regulate and monitor gas supply to gas-lubricated pump seals....

Cyclone Separators

Cyclone separators are a device for removing particles from a seal flush line to protect the seal from the abrasive wear or clogging...

Safeunit™ Ultima

Seal Water Control and Monitoring System

Safeunit Ultima is specially designed to control seal water flow and pressure in extreme conditions. This makes it ideal for...

Safeclean

Seal Water Filter System

Plant seal water filtration system, maintaining clean water supply to improve the reliability mechanical seals and gland packing and also...

Mechanical Seals

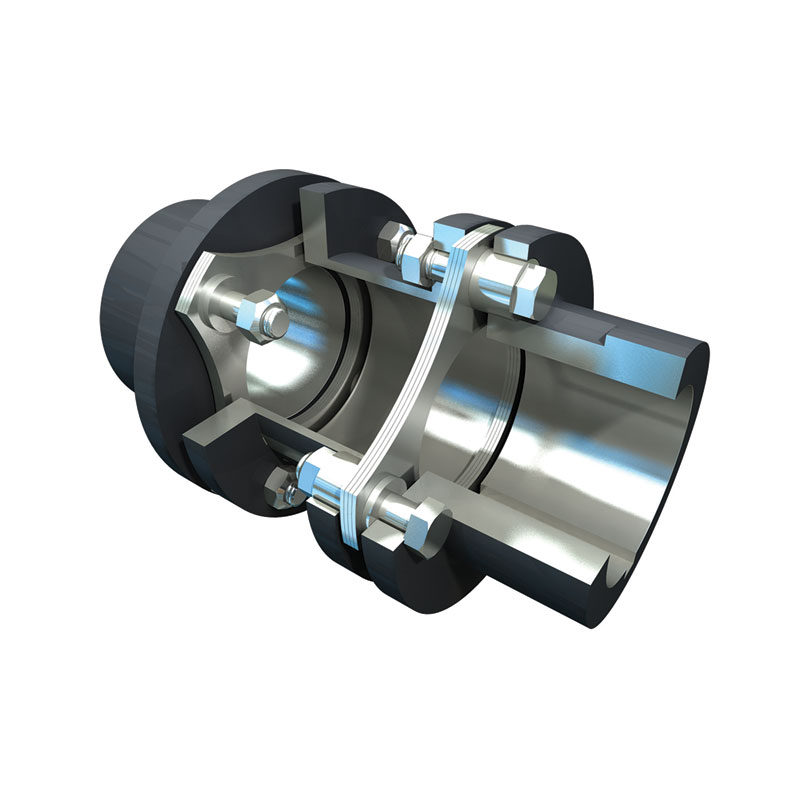

Type SB2/Type SB2A

Heavy-duty Dual-cartridge Seals

The Safeseal Type SB2A is a dual-cartridge seal. Its double-balanced design ensures the reliability and longevity of the seal...