What are Vessel and Agitator Seals?

Part 4b: Protecting Your Operations: Vessel and Agitator Mechanical Seal Arrangements and Considerations

July 31, 2025

6 Minute Read

Ensuring the performance and reliability of rotating equipment is critical in industrial operations. Vessel and agitator mechanical seals are indispensable components, particularly in processes involving closed-system mixers, agitators or reaction vessels. These seals are vital for:

- Safely managing aggressive or hazardous substances

- Maintaining pressure differentials between the vessel's interior and exterior

- Upholding stringent purity requirements in industrial applications

While terms like mixer, agitator and vessel are often used interchangeably, this blog will refer to them collectively as 'vessel and agitator seals' for simplicity.

Choosing the Right Seal Arrangement for Your Vessel

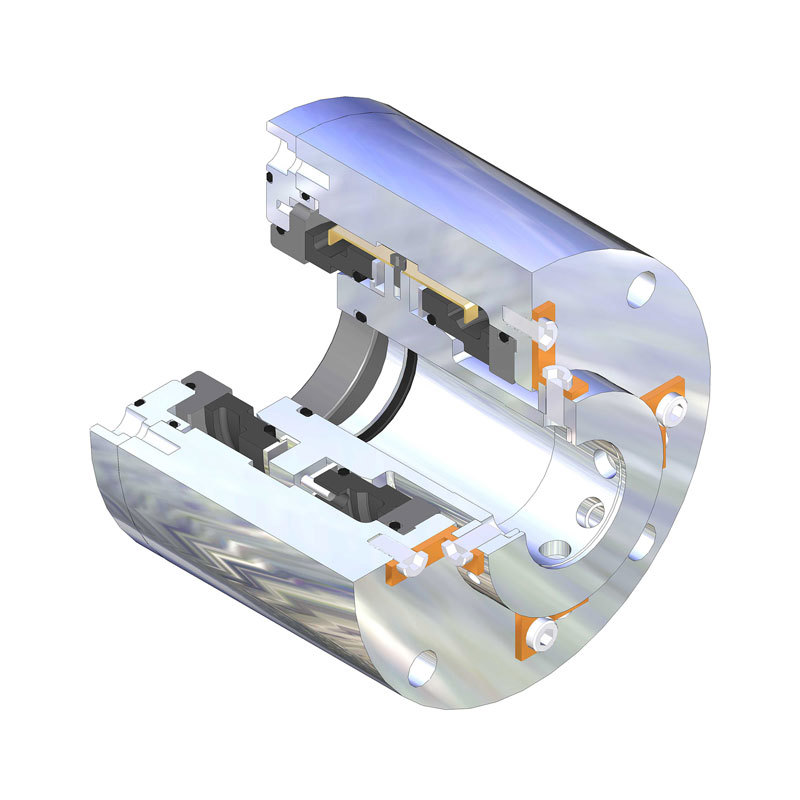

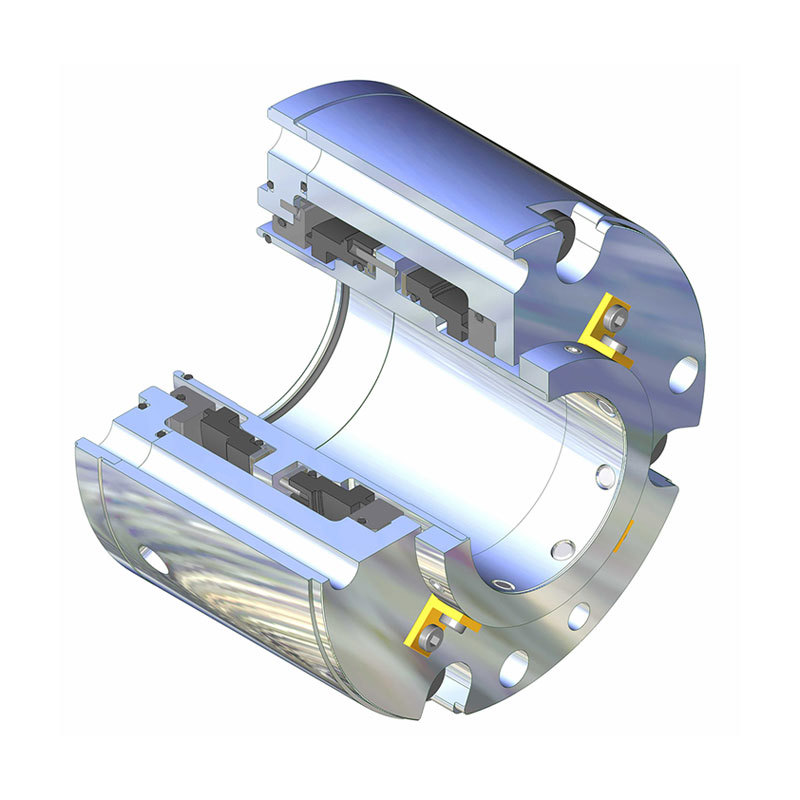

When selecting a vessel and agitator mechanical seal arrangement and system for your vessel, consider the following four main types:

Wet Contacting (W):

- Arrangement: Single and dual.

- Lubrication: Sealing faces are cooled and lubricated by the product or a barrier fluid.

Gas-Lubricated Non-Contacting (G):

- Arrangement: Dual.

- Lubrication: Sealing faces are lubricated by a pressurised barrier gas. Spiral groove technology separates seal faces by a few microns during operation, eliminating face wear and product contamination.

Dry-Running Contacting (D):

- Arrangement: Single or dual.

- Lubrication: Sealing faces are constructed from a special grade of self-lubricating carbon. Velocity is typically limited to 2 m/s (400 fpm).

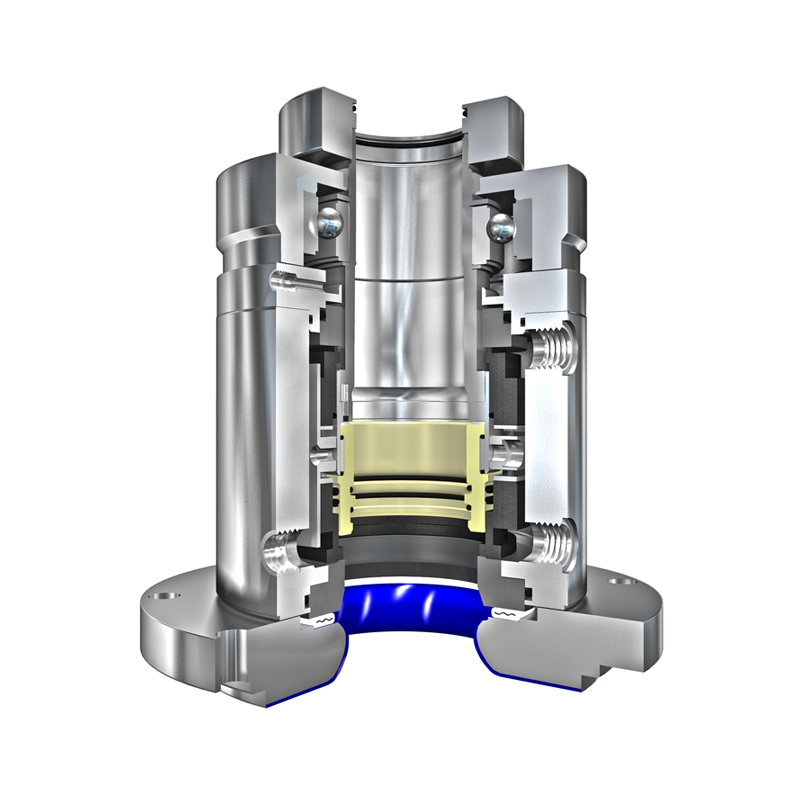

Dry-Running Non-Contacting (GD):

- Arrangement: Dual (hybrid).

- Features: Non-contacting inboard seal ensures high product purity, low heat generation, and reduced power usage. Dry-contacting outboard seal minimises barrier gas consumption.

Selecting the right seal arrangement and system depends on your application specifications, such as fluid characteristics and hygienic requirements. Dual arrangements are typically used for products that are toxic, corrosive, flammable, reactive or have high solids concentration. Non-contacting arrangements are preferred for high-purity environments.

Key Benefits of Using Vessel and Agitator Seals

Vessel and agitator seals offer several advantages over traditional pump seals, making them ideal for demanding industrial applications:

- Dry-Running Capability: Operate without a continuous fluid film, suitable for processes where seals may not always be lubricated.

- High-Pressure and Low-Speed Operation: Function effectively under high-pressure and optimised for the lower speeds typical in mixing processes.

- Robust Drive Mechanisms: Include ear drives, T-bar drives, key drives and clamp collars for secure and reliable operation.

- Accommodation of Shaft Runout: Designed to handle significant shaft misalignment, typically allowing for 0.125 inches (3 mm) of total indicated runout (TIR) at minimum.

- Versatility: Suitable for various industries like chemical processing, pharmaceutical and food production.

- Compliance: Meet industry standards such as American Petroleum Institute (API), Food and Drug Administration (FDA) and ATEX, ensuring safety and compatibility with a wide range of applications.

- Enhanced Durability: Built to withstand harsh industrial environments, extending the mechanical seal's lifespan.

These benefits make vessel and agitator seals particularly suitable for demanding industrial applications where durability and reliability are critical.

Resources

Video: Case Study: John Crane Helps Plant Reduce Contamination and Improve Reliability

Blog: Ensuring a Leak-Free Future: The Role of Mechanical Seals in Process Safety and Sustainability

Real-World Applications Across Industries

Vessel and agitator seals are used in a wide range of equipment and machinery, including pumps and compressors. Their versatility makes them indispensable in various industries, such as:

- Chemical: Handling corrosive and hazardous chemicals with precision and safety.

- Pharmaceutical: Ensuring purity and compliance with stringent regulations.

- Petrochemical: Managing the demanding conditions of petrochemical production.

- Oil and Gas: Withstanding extreme pressures and temperatures.

- Water and Wastewater: Ensuring reliable operation in clean water treatment processes.

- Power Generation: Supporting efficient and safe energy production.

- Mining: Enduring harsh conditions and abrasive materials.

- Food and Beverage: Maintaining hygiene and safety standards.

Qualified Staff: The Key to Reliable Seal Performance

Ensuring your team is fully trained and certified is as important as selecting the right seal arrangement. At John Crane, we provide comprehensive product training and asset management training to help your workforce maintain operational efficiency. Our comprehensive courses cover subjects such as mechanical seal installation, troubleshooting and maintenance best practices. Investing in qualified staff reduces downtime, minimises operational risk, extends equipment life and supports your energy transition goals.

Prioritising Sustainability and Safety

When it comes to vessel and agitator mechanical seals, sustainability and safety are paramount. Ensuring compliance with industry standards and regulations is essential for protecting the environment and the workforce. Here are the key considerations:

Compliance with Industry Standards

- API Regulations: Ensuring that seals meet the API standards for performance and safety in the oil and gas industry.

- FDA Compliance: Adhering to the FDA requirements for materials and processes in food and pharmaceutical applications.

- USP Class VI: Utilising materials that meet the United States Pharmacopeia (USP) Class VI standards, essential for medical and pharmaceutical applications.

- ADI/TSI Free: Ensuring that mechanical seals are free from Animal-Derived Ingredients (ADI) and Tallow-Sourced Ingredients (TSI) is crucial for the biopharmaceutical and food industries.

- EC 1935/2004 Compliance: Meeting European standards for materials in contact with food.

- EHEDG Standards: Adhering to the European Hygienic Engineering & Design Group (EHEDG) guidelines for hygienic design and cleanability.

- ASME BPE Standards: Complying with the American Society of Mechanical Engineers (ASME) Bioprocessing Equipment (BPE) standards for bioprocessing industries.

- 3-A SSI Standards: Meeting the 3-A Sanitary Standards, Inc. (SSI) requirements for equipment used in the dairy and food industries.

Sustainability Benefits

- Material Efficiency: Using sustainable materials and designs minimises the environmental impact, supporting the goals of reducing waste and promoting recycling within industrial processes.

- Energy Efficiency: Designed to reduce energy consumption by optimising seal performance and reducing friction losses.

- Interchangeable Faces: Some vessel and agitator seals offer interchangeable faces, including wet, dry, gas and dry-running combinations. This feature allows for the re-purposing of equipment, reducing waste and extending the lifecycle of machinery.

Safety Compliance

- Integrated Safety Features: When used with temperature transmitters and additional system protections, like pressure gauges, these seals enhance safety by monitoring and controlling operational parameters.

- Risk Mitigation: These seals help prevent accidents and equipment failures by adhering to strict safety standards, ensuring a safer working environment.

- ATEX Certification: Certain seals are certified for ATEX environments, indicating that they are safe for use where there is a risk of explosion due to the presence of flammable gases, vapours or dust that are present continuously or for long periods.

By prioritising sustainability and safety in the design and application of vessel and agitator seals, industries can achieve better environmental stewardship and ensure the well-being of their workers. Compliance with these standards meets regulatory requirements and supports the long-term viability and ethical operation of industrial processes.

Expert Seal Solutions

A thorough understanding of vessel and agitator mechanical seals is essential to maintaining the efficiency and longevity of your industrial equipment. By choosing the right seal arrangement and prioritising safety and sustainability, you can safeguard your operations and optimise performance. As experts in mechanical seal technology, John Crane provides trusted solutions to meet the most demanding industrial challenges. Explore our services, contact us or get a quote to see how we can help.

Explore more insights in our educational blog series: Part 1, Part 2, Part 3 and Part 4a.