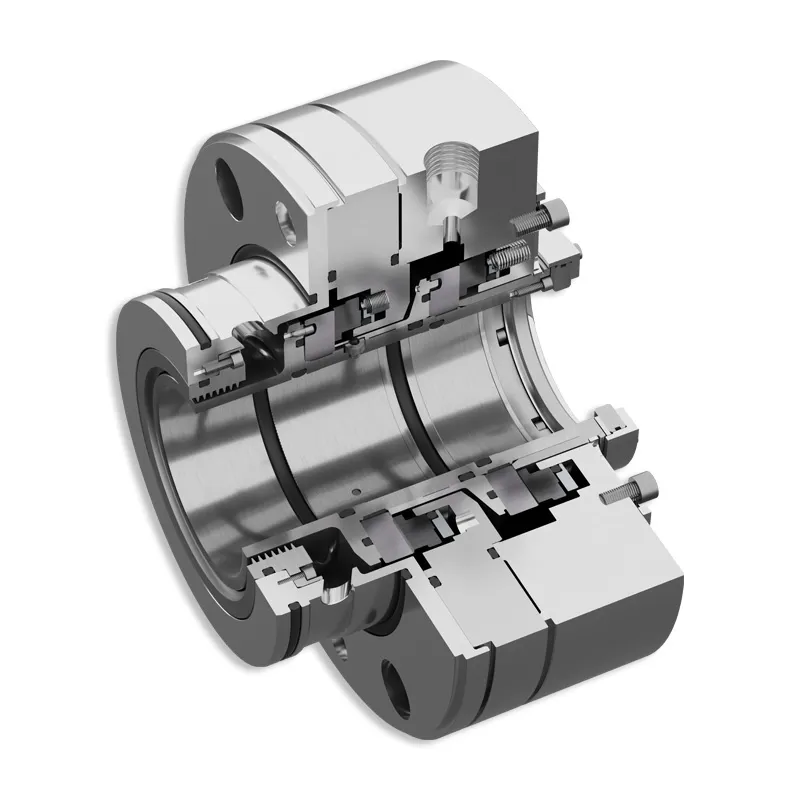

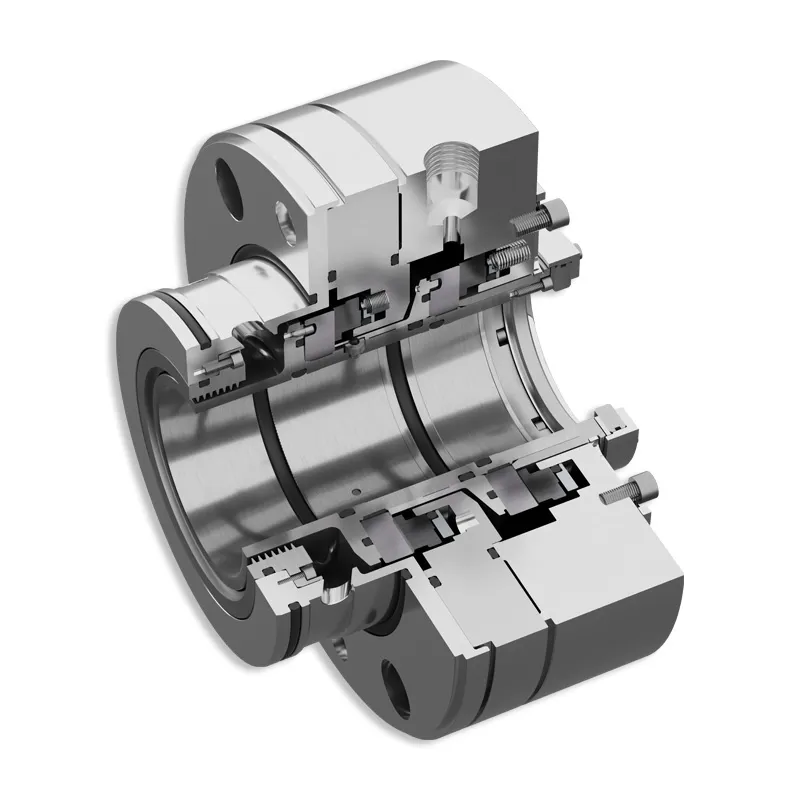

Type 8628VL

A fully non-contacting mechanical seal designed specifically for ethane and ethylene pipeline operators.

John Crane’s 8628VL is designed for ethane and ethylene pipeline operators because we know that these materials can change phase in the pipeline. Unlike other mechanical seals, its multiphase seal face lubrication design results in a fully non-contacting seal. Test results indicate that this can extend mean time between repair (MTBR) to up to 48 months and even longer. Compared to conventional mechanical seals used in ethane and ethylene pipeline applications, John Crane’s Type 8628VL can reduce the total cost of ownership by delivering more efficient and reliable operations and improving uptime.

Recommended for You

Features

Increased Reliability: With tests indicating an extended MTBR of up to 48 months and beyond, John Crane’s Type 8628VL is designed to increase equipment uptime, supporting uninterrupted pipeline operation.

Technical Competitive Difference

Non-contacting mechanical seals can operate continuously for nearly twice as long as a mechanical seal with a liquid barrier fluid.

Conventional mechanical seals operate with face contact and are lubricated by process liquid. These process lubricated seals are not capable of operating fully lubricated where phase change occurs.

The Type 8628VL is designed to operate as a fully non- contacting seal, removing both these operating challenges. Test results indicate an extended MTBR of up to 48 months and beyond.

Technical Design

We have applied our expertise in Dry Gas Seal technology to engineer the Type 8628VL mechanical seal, designed specifically for ethane and ethylene pipeline operators.

The Type 8628VL spiral grooved seal faces operate fully lubricated in the liquid, supercritical and vapour phases of ethene and ethylene without face contact.

Tests indicate an extended MTBR of up to 48 months and beyond.

Increased Efficiency –Less Flush Fluid & Less Energy

The 8628VL is designed to use up to 10 x less flush fluid.

It can significantly reduce parasitic horsepower losses compared to traditional full face contacting technology.

Face contacting seals configured as tandem seals depend upon liquid phase process fluid (ethane or ethylene) for inboard seal face lubrication and cooling, often 15 to 30 GPM of filtered flush flow for cooling of the faces. The Type 8628VL requires only 2 to 3 GPM flush fluid flow for operation.

Less Energy

John Crane’s Type 8628VL is designed to maintain seal face lubrication, eliminate face friction and reduce energy consumption for your pump.

Shorter servicing time

Unlike conventional mechanical seals used for ethane and ethylene pipelines, John Crane's Type 8628VL is serviceable via our local service centres. We maintain critical inventory elements and rebuild-ready hardware designs which should shorten lead times compared to conventional mechanical seal refurbishments.

Parameters

- Temperatures

- -26°C to 121°C (-15°F to 250°F)

- Pressures

- 103 barg (1500 psig) dynamic operating

124 barg (1800 psi) static operating

155 barg (2250 psig) static structural integrity - Speed

- 1450 to 3600 rpm Up to 25.4 m/s (5000 fpm)

Recommended Applications

- Ethane and ethylene pipelines (light hydrocarbon)

- Petrochemical and point of use feedstock markets

- Pipeline pumps