Use our new estimator tool to calculate your water and CO2 emissions savings

Value and Advantages of USP Technology

John Crane’s unique, engineered, non-contacting USP seal face technology borrows from gas seal designs to deliver a breakthrough in liquid sealing technology. The typical mean time between repair (MTBR) for traditional seals is three years, while USP seals are more than five. Here are the benefits:

-

Extended MTBR

-

Virtually eliminates cooling and flush water requirements*

-

Energy savings

-

Zero-emissions

*Dependent on the application requirements

Download the brochure Download FAQs Read Case StudiesRecommended for You

Why USP?

USP seal face technology helps overcome the most rigorous sealing challenges. It improves seal and pump reliability, prevents unplanned downtime and reduces operating costs across a broad range of severe-service conditions, such as:

- Low-lubricity conditions

- Dry running conditions

- High heat

- Friction

- Caustics/liquors

- Viscous fluids

- Polymerizing fluids/solidifying

- Dirty fluids

It is also suitable for a variety of process industries with challenging process fluids, for example:

- Chemical process liquids

- Volatile organic compounds (VOCs)

- Poor lubricity fluids

- Sour services (H2S)

- Foul water

- Abrasives

How it Works

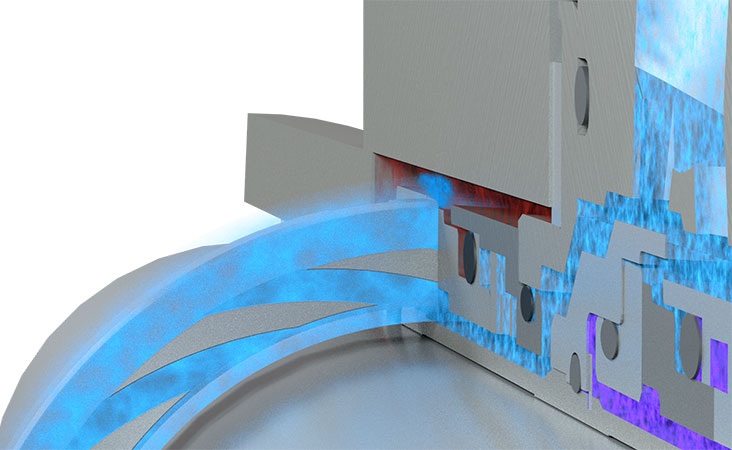

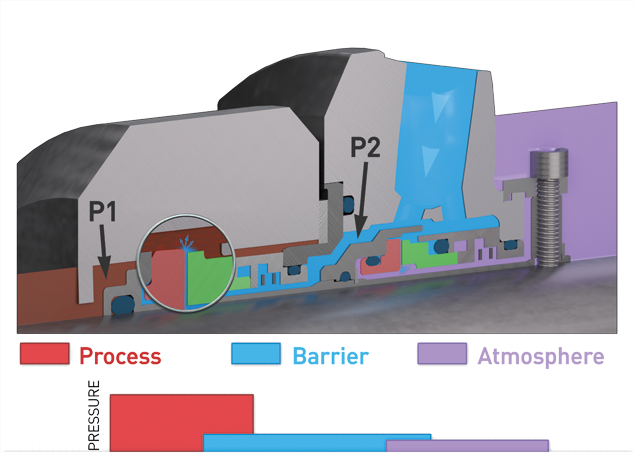

The basic concept of John Crane’s solution is that the conventional seal is replaced by a low-volume, high-pressure “pump”—the USP seal. This pump propels a minute quantity of barrier liquid along the path usually sealed by the mechanical seal faces and into the product side. Because the product side is at a higher pressure than the barrier liquid, this seal is said to pump “upstream.”

Mechanical seals require a narrow gap between faces to allow a lubricating film to work; the gap must also be optimized to eliminate leakage. Debris in process fluids can create deposits, damage faces and cause hang-ups. This is where USP comes in — it extends seal life and the MTBR of the pump.

USP Support System for Optimal Performance and Reliability

Mechanical seals using Upstream Pumping seal face technology have support system requirements unique from traditional dual mechanical seals. A standardized support system is available to supply our standard Upstream Pumping seals. Using one of these systems eliminates the need to design a custom system, saving costs, making operation simple and minimizing space requirements. For more information on the GS USP–R and GS USP–D

Which Global Standardized Upstream Pumping Support System (GS USP) do you require?

Upstream Pumping (USP) is a seal face technology unique to John Crane, which adds the spiral grooves, commonly seen in non-contacting gas seals, to the inboard seal of a dual mechanical seal running on a liquid barrier fluid. The addition of spiral grooves provides unique operational advantages, including improved reliability, virtually eliminates cooling and flush water requirements and lower power consumption.

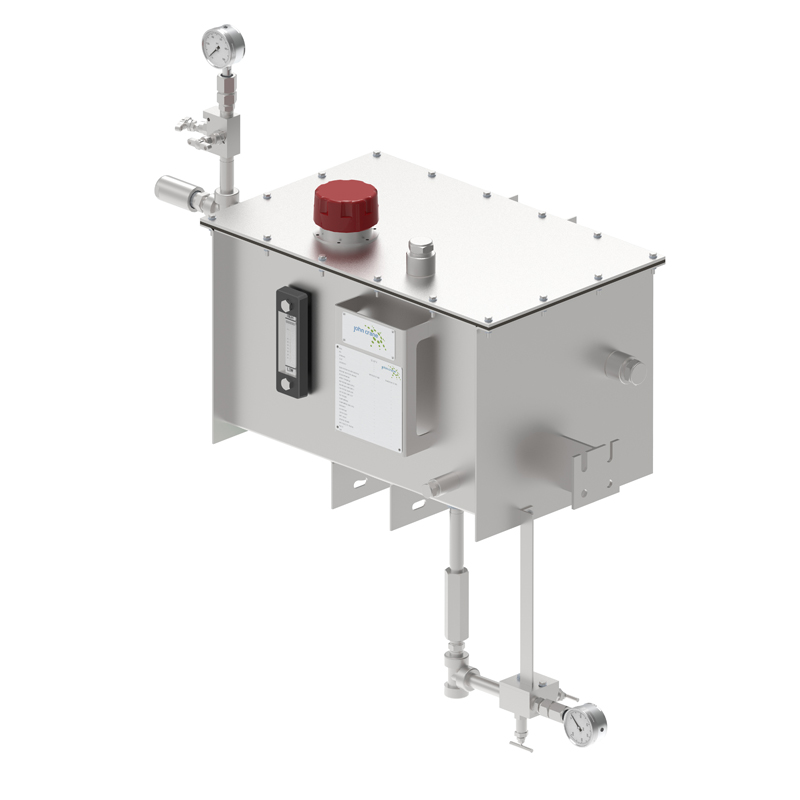

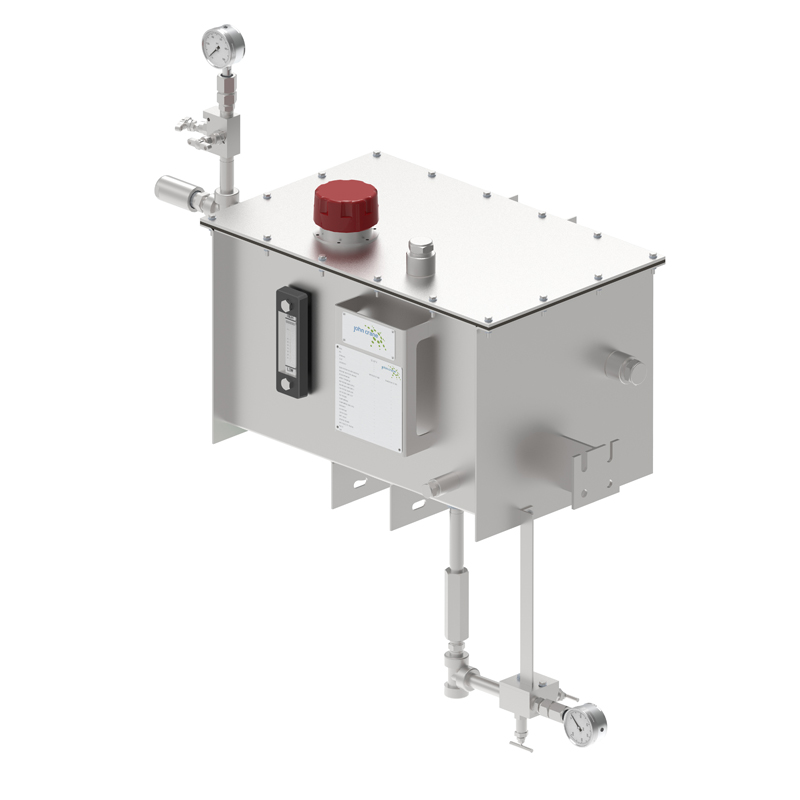

Mechanical seals using USP have support system requirements unique from traditional dual mechanical seals. A standardized support system is available to supply our standard USP seals. Using one of these systems eliminates the need to design a custom system, saving costs, making operation simple and minimizing space requirements.

The system is available in two variants GS USP-R which includes a reservoir and GS USP-D, which connects directly to the water supply. When to use each system depends on several variables including, fluid type, barrier pressure and fluid quality. Complete the criteria below to determine the best support system for your application.

Is the process compatible with water?

Is the site water supply clean (particle size less than 10μ)?

Does the seal require barrier pressure greater than 0.2bar (3psi)?

Is the system fed by a drinking water connection?

Direct Type (GS USP-D)

The Global Standardized Upstream Pumping Support System (GS USP) is an optimized, pre-engineered design based on John Crane’s fluid control expertise and engineering excellence. The GS USP is a best-practice solution that significantly reduces specification review and delivery schedules, delivering low pressure barrier water for optimal mechanical seal performance and reliability.

Direct Type (GS USP-D) with added filter

The Global Standardized Upstream Pumping Support System (GS USP) is an optimized, pre-engineered design based on John Crane’s fluid control expertise and engineering excellence. The GS USP is a best-practice solution that significantly reduces specification review and delivery schedules, delivering unpressurized barrier water for optimal mechanical seal performance and reliability.

Reservoir Type (GS USP-R)

The Global Standardized Upstream Pumping Support System (GS USP) is an optimized, pre-engineered design based on John Crane’s fluid control expertise and engineering excellence. The GS USP is a best-practice solution that significantly reduces specification review and delivery schedules, delivering unpressurized barrier water for optimal mechanical seal performance and reliability.

Reservoir Type (GS USP-R) (with added filter)

The Global Standardized Upstream Pumping Support System (GS USP) is an optimized, pre-engineered design based on John Crane’s fluid control expertise and engineering excellence. The GS USP is a best-practice solution that significantly reduces specification review and delivery schedules, delivering unpressurized barrier water for optimal mechanical seal performance and reliability.

Consider an alternative fluid such as oil and consult John Crane

A special design may be required

Environmental Benefits

The Power of Water and Energy Savings

With USP, the quantity of water required for cooling is nearly eliminated. Energy usage is also significantly reduced compared to traditional sealing methods.

Reduce Your Carbon Footprint

John Crane supports your corporate CO2 emissions reduction strategies. 12.4 metric tons of CO2 can be saved annually by adding a John Crane USP seal to one pump.

|

|

Seal MTBR |

Annual |

Annual |

Average Running |

|

Traditional Seal |

3 years |

4,200 m3 |

19,500 kWh |

= $4,200 |

|

USP Seal with GS USP |

5+ years |

4.9 m3 |

1,970 kWh |

= $290 |

|

Net Results |

2 years |

4,195 m3 |

17,530 kWh |

= $3,910 |

*Assumes a water cost of $0.35 per m3. Water cost varies greatly depending on geographical location and water source.

*Power cost is based on $0.142 per kWh, which is typical average cost for the US in Q3 2022.

Note: Additional savings for maintenance, such as cost to top-up reservoirs, cost for seal refurbishment or equipment

downtime are not included in this example and will also be realized.

A seal for any application

Type 5620/5620P

Universal Cartridge Seal Family — Dual Cartridge O-ring Seal

The first truly universal cartridge seal, the Type 5620/5620P will change your approach to sealing. Since the 5600 Series components...

Type SB2/Type SB2A

Heavy-duty Dual-cartridge Seals

The Safeseal Type SB2A is a dual-cartridge seal. Its double-balanced design ensures the reliability and longevity of the seal...

Type 8610/8620

Balanced Stationary Multi-spring High Duty Mechanical Seal

The type 8600 seal is available in single, dual pressurized and dual non pressurized arrangements for the most extreme pressures and speeds, from our high…