Introducing John Crane’s New Type SB2 USP/Type SB2A USP Heavy-Duty Cartridge Seals with Upstream Pumping Seal Face Technology

April 19, 2023

5 Minute Read

Type SB2/Type SB2A heavy-duty dual-cartridge seals are designed to operate in harsh conditions, such as abrasive fluids and slurry duties. Their double-balanced design ensures reliability and longevity in these demanding conditions. Even though these seals are high performing, there are situations such as high-heat generation, low-lubricity or dry-running conditions that can curtail mechanical seal life.

To combat these severe-service applications, John Crane has added the capability to use our unique Upstream Pumping (USP) seal face technology. This one-of-a-kind seal face technology applies dry gas seal designs to deliver a breakthrough in liquid sealing technology.

The resulting new Type SB2 USP/Type SB2A USP seals are ideal for use in pumps and other rotary equipment in pulp mills, minerals processing and other slurry duties up to 40% solids by weight and a solids hardness of eight Mohs.

The Type SB2 USP/Type SB2A USP uses spiral groove

technology to improve reliability, nearly eliminate water

consumption and reduce power usage.

Why USP Technology?

USP seal face technology helps overcome the most rigorous sealing challenges. It improves seal and pump reliability, prevents unplanned downtime and reduces operating costs across a broad range of severe-service conditions, such as:

- Low-lubricity conditions

- Dry running conditions

- High heat

- Friction

About the Technology

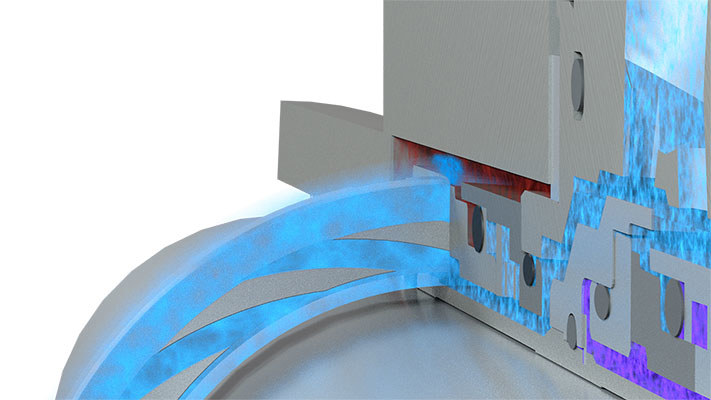

USP is a seal face technology unique to John Crane, which adds the spiral grooves, commonly seen in non-contacting gas seals, to the inboard seal of a dual mechanical seal running on a liquid barrier fluid. The grooves draw in the barrier fluid and pressurize it as it reaches the tips of the grooves. This pressurization has the combined effect of causing the seal faces to “lift-off” each other, running with zero contact, and it can cause a low-pressure barrier fluid to leak backward by being pushed into a high-pressure process stream.

More information on this novel technology, including a video showing the operation of the spiral grooves, can be found here. Using this technology unlocks several benefits to mechanical seals, including:

- Extending mean time between repair (MTBR)

- Nearly eliminating seal water consumption

- Decreasing power usage requirements

- Reducing emissions

- Lowering costs

Support System

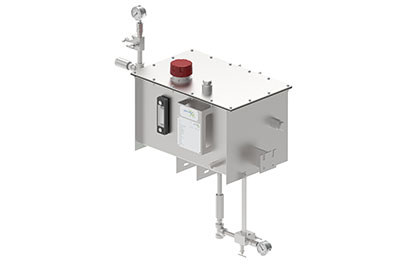

Like other dual seals, a USP seal requires a support system to function properly. However, the needs of a USP seal are much simpler than a traditional seal. Therefore, the support system can be a basic design that is only required to supply a low-pressure barrier fluid and replenish fluid that is pumped across the inboard seal faces. This straightforward, low-pressure support system may lead to a lower initial purchase cost compared to a traditional system for a dual mechanical seal.

The GS USP is John Crane’s globally standardized USP support system. It is designed to fit directly into the site water supply, has a small footprint, and is easy to install and operate.

Typical Applications

The Type SB2 USP/Type SB2A USP seal is ideal for use with environmentally hazardous and abrasive fluids, most often used in pumps in pulp mills and minerals processing. Already well established in these industries, the Type SB2/Type SB2A is recognized for its reliable performance. Typical applications within a pulp and paper mill include liquor, condensate, stock and coatings.

The Type SB2 USP/Type SB2A USP can also help improve mechanical seal reliability, generate a substantial savings in seal water and reduce power requirements in the mining industry. Common applications include slurries, corrosive fluids, filtrate and tailings.

In addition to these industries, the new seal types provide a solution for challenging slurry applications in the chemical, water/wastewater, food and beverage, including sugar processing and general industry markets.

Partner with USP Seal Face Technology Experts

Are you ready to learn more about the benefits of using the Type SB2 USP /Type SB2A USP heavy-duty cartridge seal? At John Crane, we have over 100 years of experience, so contact one of our experts today.