Type 93AX Coaxial Separation Seal

Reduce risk. Reduce downtime. Enhance efficiency. Our latest coaxial separation seal is engineered for success.

Designed for Your Success

The Type 93AX coaxial separation seal delivers a safer, more reliable and more efficient dry gas sealing solution.

Shaped by global customer insight, it’s engineered to help you meet your sustainability and regulatory requirements, while also creating real cost savings.

And it’s backed by our expansive global network of turbo service centres.

Seven Reasons Why the Type 93AX from John Crane is the New Benchmark for Separation Sealing.

Avoiding Failure. Even in Failure Scenarios.

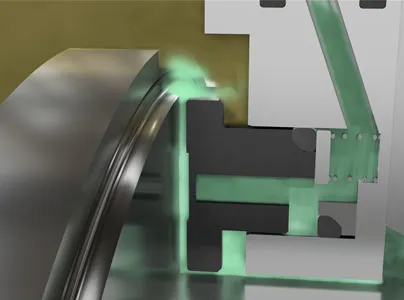

Our seals are used in critical applications where failure isn’t an option. But that doesn’t mean compressors always run optimally, or that human error never occurs. The Type 93AX Coaxial Seal is designed to work, even in the event of multiple failure scenarios.

Scenario One:

Standard Operating Mode

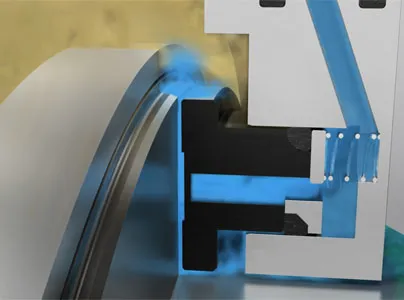

Standard Operating Mode

For day-to-day, normal working conditions, the separation seal behaves in the way you’d expect - protecting the dry gas seal from the bearing oil. Gas in the inner diameter is directed towards the secondary vent.

Scenario Two:

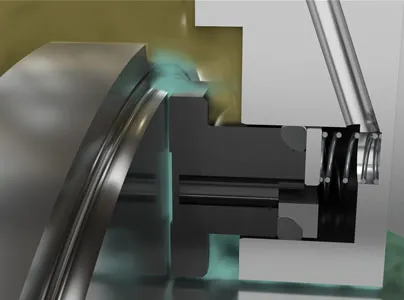

Separation Gas Failure Mode

Separation Gas Failure Mode

In the event of separation gas failure, the seal is engineered so that high-pressure gas from the dry gas seal side creates flow towards the bearing side.

Expert Insights

Find Out More About the Type 93AX Coaxial Separation Seal

We have a broad range of resources designed to help you understand more about the features and benefits of the Type 93AX Coaxial Separation Seal.

Product Brochure: Engineered for Success

Infographic: Seven Reasons Why the Type 93AX is the New Benchmark for Separation Sealing

Blog: Engineering a New Benchmark in Compressor Protection

Infographic: Three Modes of Operation for Three Scenarios

Blog: The Drive for Greener Energy

Application Sheet: Oil and Gas, Upstream Offshore

Application Sheet: Oil and Gas, Gas Transportation

Application Sheet: Energy Transition, Hydrogen, CCUS

Blog: Why the groove makes all the difference

Blog: Beyond the barrier: How separation seals safeguard dry gas seals and reduce emissions

Blog: Revolutionising compressor reliability: The Type 93AX coaxial separation seal that cuts nitrogen use by 80%

Take a closer look at the Type 93AX, with detailed features, parameters, recommended applications and technical documentation