Beyond the barrier: How separation mechanical seals safeguard dry gas seals and reduce emissions

October 20, 2025

4 Minute Read

Why are separation seals so vital?

Dry gas seals and separation seals are vital components in centrifugal compressors, acting as “invisible guardians” that ensure efficient operation and minimise emissions. A key part of this system is the separation seal, which prevents oil migration towards the atmospheric side of the seal, which is a leading cause of dry gas seal failure and unplanned downtime. These seals maintain a controlled flow of separation gas – nitrogen or air, to both the process side and the bearing side, thereby avoiding fugitive emission in the bearing housing and protecting the seal environment. This principle applies across all seal configurations—tandem, double or single—making separation seals essential for both performance and environmental compliance.

What happens if a dry gas seal gets contaminated?

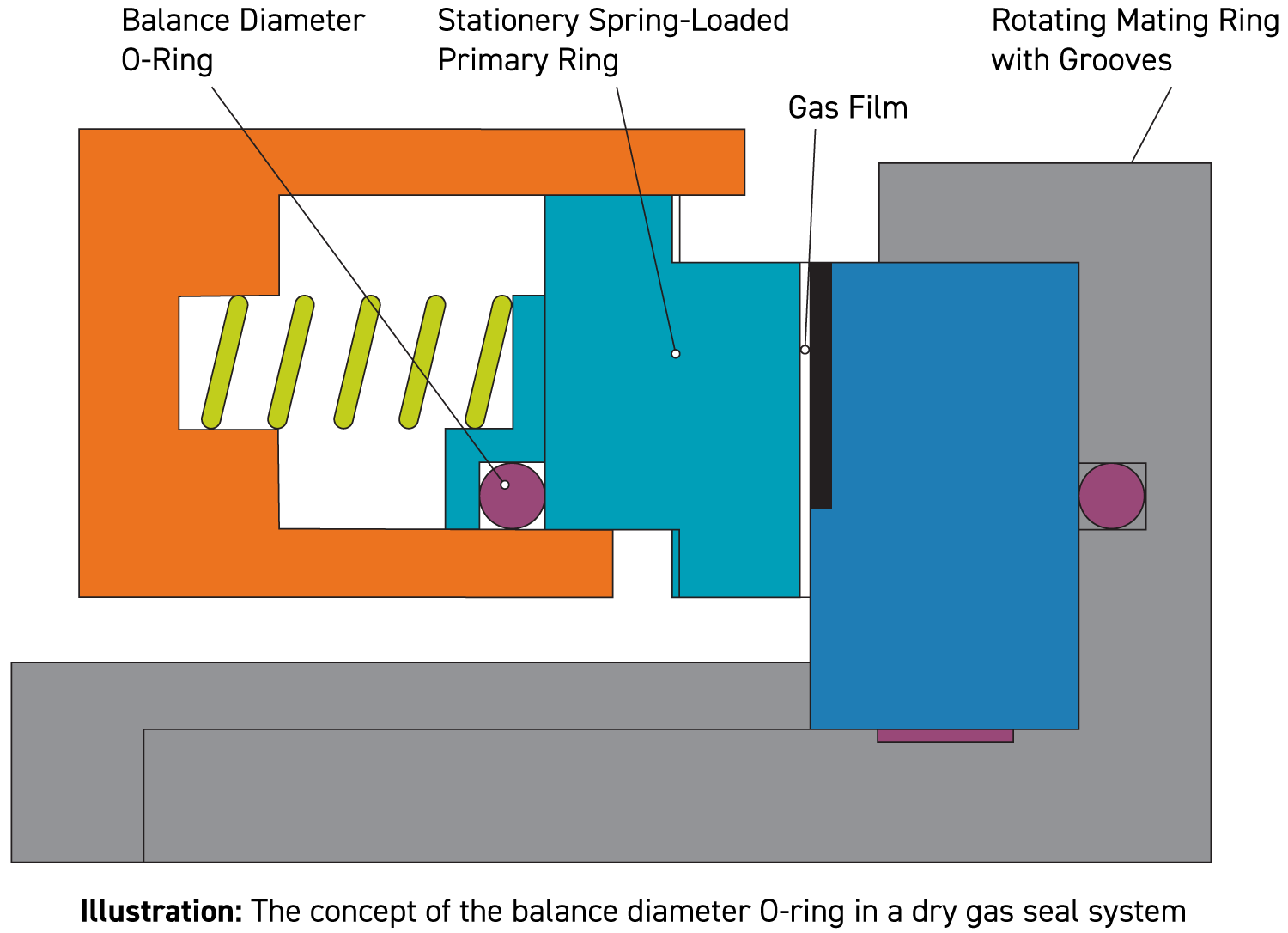

In a dry gas seal system, the balance diameter sealing element (i.e., O-ring or primary ring) plays a crucial role in maintaining the seal's integrity. It is designed to move slightly. These tiny movements are essential because the gas film between the primary ring and its counterpart (the mating ring) is constantly fluctuating due to pressure changes, shaft vibrations, etc.

This movement balances the forces acting on the seal. If the primary ring is blocked and cannot move freely, two problems can occur: either the gap between the rings stays open, causing gas to leak, or the rings stay in contact, generating excessive heat that can lead to a complete seal failure. Even small contaminants, such as oil droplets, can interfere with this movement and trigger such failures.

What are the differences in separation seal designs?

The simplest type of separation seal in a dry gas seal system is a labyrinth, which uses a pressurised gas—typically nitrogen or air—introduced at its center. This gas flows in two directions: one toward the bearing housing and the other toward the vent area at the back of the dry gas seal. Because the labyrinth is a static (non-moving) component, its design must ensure a minimal gap between the shaft and the seal tips during normal operation, while still accommodating rotor vibration and runout. However, this gap can widen under off-design conditions, increasing the flow rate of separation gas. If the flow toward the bearing housing is too low, bearing oil can migrate backwards, potentially contaminating the seal.

More advanced bushing-type separation seals use carbon rings that surround the shaft. These come in two types:

- Clearance bushings (See Type 93FR and Type 93LR), which float on a gas cushion or lift-off when the rotor spins.

- Contacting bushings (e.g., Type 83), which touch the shaft and offer lower gas flow rates but can wear over time, potentially affecting the movement of the balance diameter seal.

All bushing seals are cartridge designs, meaning they are modular and help limit process gas intrusion during a dry gas seal failure. However, they are less effective at stopping oil ingress if the separation gas supply is lost.

Why is the new Type 93AX separation seal the new benchmark in separation sealing?

Building on lessons from previous designs and customer feedback, we've introduced the Type 93AX coaxial separation seal, which represents a significant advancement in sealing technology. This mechanical seal operates axially—similar to a dry gas seal—between a primary ring and a mating ring, using TriHex grooved technology to inject separation gas directly into the primary ring. This creates a gas film that lifts and separates the rings, enabling contact-free operation and reducing wear.

The separation gas flows also in two directions: outward toward the compressor vent and inward toward the bearing housing. The grooves generate high exit velocity, effectively blocking oil migration toward the dry gas seal. This design dramatically reduces gas consumption and has been rigorously tested under failure conditions, including loss of separation gas and catastrophic dry gas seal failure.

In both scenarios, the seal maintains integrity, allowing only minimal process gas leakage and preventing oil ingress. The cartridge is robust, capable of withstanding pressures up to 70 barg from the vent side. Like all separation seal designs, whether bushing or coaxial, the Type 93AX requires clean separation gas, typically sourced from the secondary seal gas system, ensuring particle cleanliness below 1µm. If air is used, it must be filtered separately to maintain performance.

Designed for Your Success

To ensure the reliable and long-term performance of a dry gas seal, it is critical that the vent area, the atmospheric side of the compressor, always remains clean. This requires the installation of a separation seal between the vent area and the bearing housing, preventing oil from migrating toward the back of the dry gas seal. The newly launched Type 93AX separation seal addresses this need by effectively blocking oil ingress while also significantly reducing separation gas consumption.

Its advanced design has been thoroughly tested under various failure scenarios, and results confirm that no oil reaches the dry gas seal area, even in adverse conditions. This makes John Crane's Type 93AX a robust and efficient solution for maintaining seal integrity and protecting compressor components.

For more information about the Type 93AX, visit our landing page.