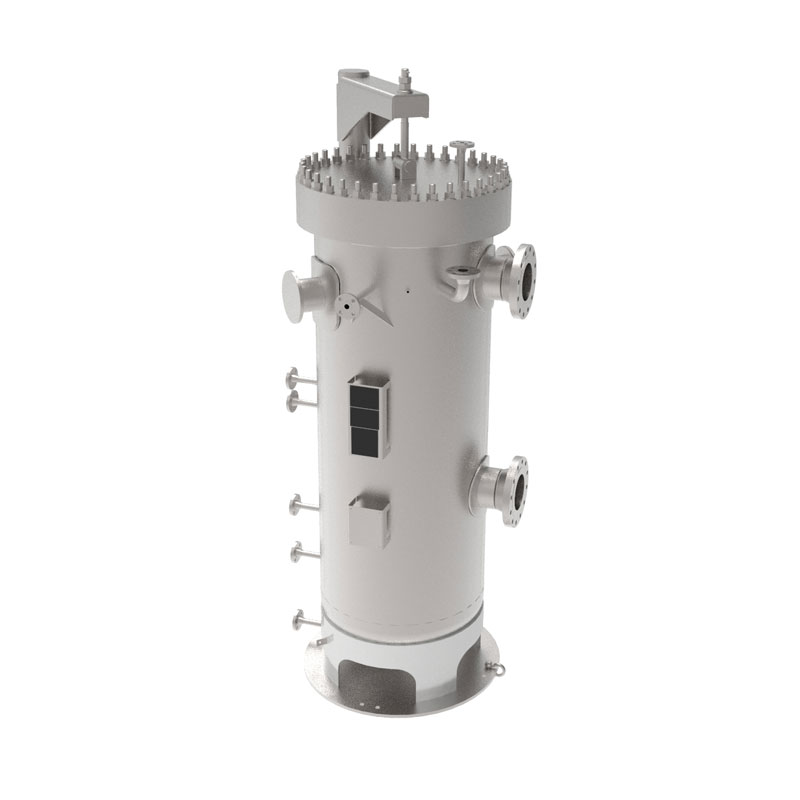

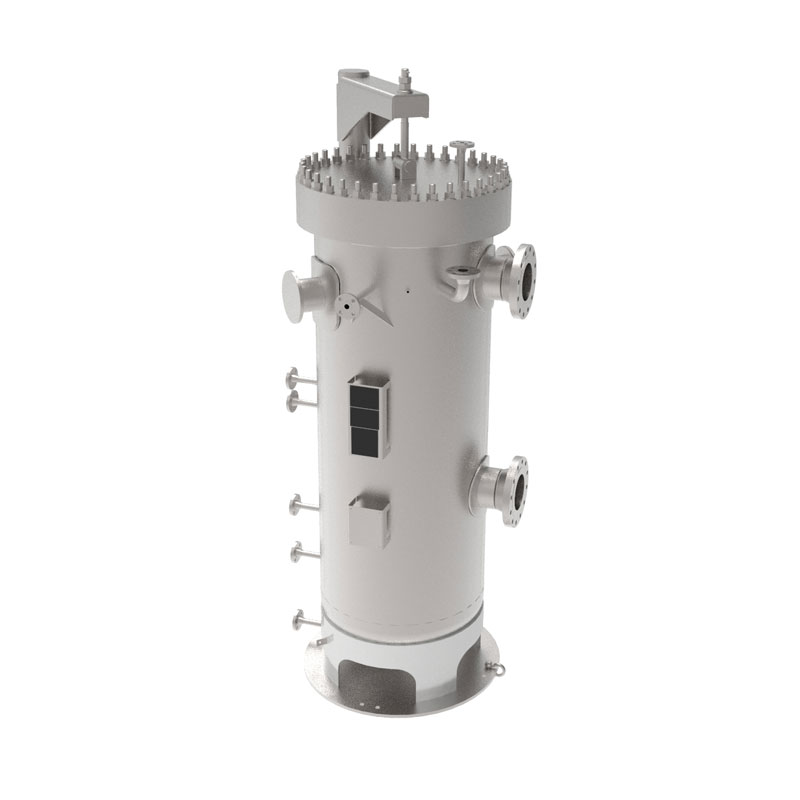

HFC 1001, 1003, 1005, 1009 & 1020

High Flow Liquid/Gas Coalescer

Used in process gas filtration applications in refineries, petrochemical and chemical plants, the John Crane HFC liquid/gas coalescer protects critical process equipment by removing fine liquid droplets and solids from the gas stream. Available in five sizes of one, three, five, nine and 20 elements, gas flow up to 9000 m3/hr (5300 SCFM) can be accommodated.

×

Recommended for You

Features

- California Residents: PROPOSITION 65 WARNING

- Particle filtration coupled with coalescence to remove solids and aerosols

- Filtering of process and fuel gases with cleanliness requirements down to 0.3 micron and removal of 99.9% of solids

- Removal of aerosol liquids down to 99.9% efficiency

- High dirt-holding capacity

- Optimization of element length/diameter ratio, inlet/outlet location and flow control to enable the lowest pressure drop across elements

- Special oleophobic coating on elements for improved drainage and reduced pressure drop

- Simplified welded vessel construction to handle a wide range of gas flow rates

Parameters

- Temperature Limits

- -29° to 175°C/-20° to 347°F (fuel gases)

-29° to 100°C/-20° to 212°F (process gases) - Pressure Limits

- Up to 30 barg/441 psig (fuel gases)

3 to 10 barg/44 to 147 psig (process gases) - Flow rate

- 450 m3/ hr (265 SCFM) per element (handling capacity varies depending on number of elements in the pressure vessel)

Recommended Applications

- Protection of burner tips in furnaces from fouling created by fuel gas contaminants

- Protection of molecular sieve dryer beds (dehydrators) from process gas impurities

- Protection of amine units in refineries from process sour gas contaminants