Couplings Explained

Part 1: An Overview

August 21, 2025

4 Minute Read

What is a Coupling?

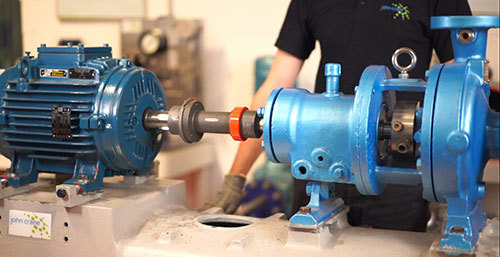

Pump couplings connect the shaft of a rotating pump to the drive shaft of the driving equipment, such as a motor or turbine. This enables the power and rotation of the driving equipment to be transmitted to the pump.

Most pump couplings are flexible couplings that accommodate misalignment between shafts, and in the case of elastomeric couplings, help dampen vibrations.

We'll explore the main pump coupling categories further, below. But first, let's review some key considerations when selecting and installing the best coupling for a particular pump or plant condition.

Choosing the Right Coupling

Ensuring the longevity and maintaining optimal efficiency of a rotating pump relies heavily on choosing the proper coupling.

When it comes to coupling discs, size matters significantly.

A coupling that is too small may lead to overloading and failure, resulting in system vibrations and potential damage to crucial components such as bearings and seals. It could also require unscheduled equipment maintenance, causing operational disruptions and financial losses.

On the other hand, an excessively large coupling introduces additional weight and overhung moments on the equipment shafts, causing excessive wear on the bearings which, can lead to damaging vibrations. Additionally, the coupling may not even be the weakest point in the equipment train, meaning that in cases of torque overload or excess misalignment, the coupling may not fail, but instead a more expensive part will fail.

Installing Couplings Correctly

When installing a coupling, it is crucial to dedicate time to aligning the equipment shafts properly to minimise vibrations and misalignment. This can significantly extend the lifespan of the equipment train and the plant's overall profitability.

Misalignment comes in three forms:

- Axial misalignment – Occurs when the gap between the shaft ends is not per specification, or goes out of specification while running due to factors like thermal shaft growth, pipe strain, etc.

- Angular misalignment – The shafts are positioned at an angle other than zero degrees between their centerlines, or an angle is created while running due to base plate movement, pipe strain, etc.

- Parallel offset misalignment – The shafts have an offset between their centerlines, or an offset is created while running due to base plate movement, pipe strain, etc.

These misalignments will be different in the horizontal and vertical planes. However, it is common for most systems to experience a combination of all three types of misalignment.

Not understanding and addressing these misalignment issues can lead to extra loading on the coupling and equipment bearings. Over time, this will cause wear, leading to increased vibrations. In turn, these can harm the life and profitability of the equipment train, including failure of the bearings, couplings and mechanical seals.

Types of Couplings

What are Flexible Couplings?

Besides transmitting power and rotation between the drive and driven equipment, flexible couplings can accommodate a specified amount of misalignment that is present in all equipment trains. Even so, it is in the best interest of the life of your equipment—bearings, seals, couplings, etc., to minimise the potential of associated issues by aligning your equipment shafts while installing the coupling.

Examples of flexible couplings include elastomeric, mechanical and disc:

- Elastomeric couplings

- Do not require lubrication

- Suitable for low to medium torque and speed applications

- Quick and easy to install

- Maintenance free

- Ideal applications: ANSI pumps, conveyors, fans and blowers

- Mechanical couplings

- Require lubrication

- Tendency to wear requiring periodic maintenance and spares

- Suitable for medium and high torque and speed applications

- Ideal applications: steel mill equipment

- Disc (membrane) couplings

- Do not require lubrication

- Suitable for medium-to-high torque and speed applications

- Maintenance free

- Excellent inherent balance

- Designed for infinite life

- Ideal applications: electric motors and turbine drives in critical process industries, marine and power generation

What are Rigid Couplings?

Just like flexible couplings, rigid couplings are used to transmit power and rotation between the drive and driven equipment.

While rigid couplings have a simpler design and are more cost-effective, they cannot accommodate misalignment and are mainly used in applications where there is a need to support the weight of equipment due to a lack of the thrust bearings in the equipment.

Examples of rigid couplings include flange, sleeve or muff, and clamp. Rigid couplings:

- Are ideal for vertical applications with no thrust bearing in the pump

- Support pump shaft and impeller

- Allow for the axial setting of the pump impeller

Coupling Experts

We hope that you found this overview of couplings informative. Be sure to keep an eye on our blog section for additional content on couplings in this educational series. We'll also cover topics such as mechanical seals, pump packing and more. And, when it comes to keeping your rotational equipment running 24/7, John Crane's comprehensive range of couplings has you covered. Learn more here.