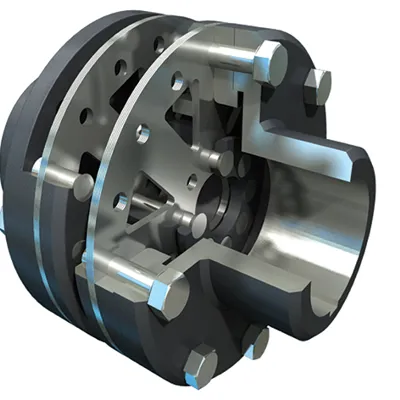

TSKL/TLKL Couplings

T Series Close Coupled Radially Split Coupling for Medium to High Torque Applications

John Crane’s Metastream® TSKL/TLKL Series of close-coupled membrane (disc) couplings are specifically designed as a direct replacement for lubricated gear couplings, even when the shaft separation is very small, typically 3mm (1/8”). They are metallic membrane couplings that incorporate industry leading scalloped, stainless steel, flexible membranes. They use the same technology used on the T Series couplings that meet API 610 (ISO 13709) and ISO 14691 standards. With an excellent power to weight ratio and fit-and-forget reliability, these couplings are ideally suited for your equipment with short shaft separations and higher speeds. The TSKL is a six-link design for smaller power requirements, and the TLKL is an eight-link design for larger power requirements. The coupling provides a strong level of angular, lateral and axial misalignment, while maintaining a high level of balance integrity. An option for spark resistance is available.

Recommended for You

Features

- California Residents: PROPOSITION 65 WARNING

- Easy to install.

- Can be supplied to meet ISO 13709 (API 610) specification.

- Intrinsic balance meets AGMA standard 9000 class 9.

- Coated carbon steel for corrosion protection.

- Fit and forget: The TSKL/TLKL coupling is designed for infinite life, and with correct machinery alignment will out last the machines it is connected to.

- Overload protection: The coupling is fitted with overload collars to protect the membranes in the event of severe torsional overload.

- Low imposed loads: The membranes have been designed to optimize their torque capability, while minimizing the reaction forces due to misalignment.

- Zero maintenance: The coupling has no relative moving parts, and hence requires no lubrication or routine maintenance.

- No backlash: The coupling design, with fitted bolts, and torsionally stiff membranes ensures that there is zero backlash.

- Spark-resistant option: Hazardous areas in refinery operations require spark-resistant couplings. This is by replacing the overload collars with components manufactured from non ferrous metals.

- Standard features: The coupling hubs are fitted with puller holes as standard. Self-locking threads ensure the hub bolts remain in place under all vibration conditions. The transmission unit has compression and jacking bolt features to ease assembly and removal.

Parameters

- Maximum Rating

- 33,000 kW/1,000 rpm or 4,425 HP/100 rpm

- Maximum Continuous Torque

- 315,200 Nm or 2,789,756 lb.in.

- Maximum Peak Torque

- 630,300 Nm or 5,578,628 lb.in.

- Maximum Speed

- 18,000 rpm

- Maximum Bore (Shaft)

- 364 mm or 12”

Recommended Applications

- Process pumps

- Electric motors

- Gearboxes

- Driven machinery

- Other rotating equipment

- High Duty Pumps

- Power generation

- Pumps

- Standard bore process pumps

- High speed pump and gearbox

- Chemical processing

- API 610 Pumps

- Oil and gas (refineries)