Upstream Pumping (USP): Supporting chemical plant processing

Part 1: The realities of chemical industry processing, and how USP can help

January 14, 2026

2 Minute Read

The chemical industry faces more processing challenges than any other. The oil and gas, polymers and similar industries work with hazardous materials, but few manage as many caustic, toxic, and abrasive solids, gases and low-lubricity fluids as those working with chemicals and petrochemicals.

Harsh: The reality of chemical processing

Acids, solvents, slurries and polymerising fluids – often at extreme temperatures and high pressures – present process difficulties.

Gas leakage, or any form of emissions escape, is a single issue causing multiple health, safety and operational problems.

Poor seal lubrication can cause premature seal wear and increased leakage, reducing mean time between repair (MTBR), while increasing unplanned downtime and the maintenance burden. Fugitive emissions compromise corporate sustainability goals and risk breaching local regulatory controls.

How we help

John Crane is committed to helping chemical industry customers meet the challenges of managing difficult materials and processing environments. Our innovative, transformative sealing technologies and solutions include Upstream Pumping (USP).

We built our reputation on mechanical seal innovation, and USP can help operators mitigate these potential issues, as demonstrated by the successful implementation of USP applications across the chemical industry.

What is Upstream Pumping technology?

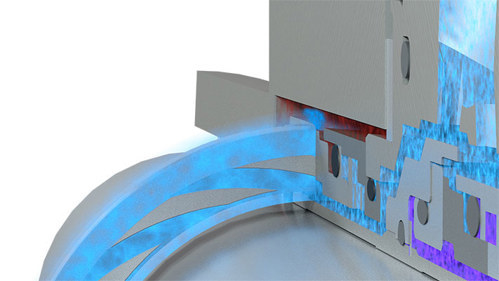

USP is a mechanical seal face technology that pumps a small amount of barrier fluid ‘upstream,’ into the high-pressure product stream, to prevent contact friction, dry-running and subsequent wear in rotating equipment by separating the seal faces.

Selected John Crane seals use spiral groove technology, where grooves are micromachined on the seal face to create a hydrodynamic lift, ensuring a high-pressure seal in liquid and vapour phases. It's a step change in extending equipment life, reducing power consumption and virtually eliminating emissions.

Why John Crane USP solutions excel in caustic and abrasive environments

Different non-contacting John Crane dry gas seals, including the Type 8628VL and the Type 285 use our spiral groove technology. It's just one innovation to meet the industry-specific challenges of chemical processing.

For example, the Type 285 was the first seal to utilise this non-contacting technology in cryogenic applications, where self-lubricating grooves gather and compress the vapourised liquid. This enables the seal to operate on a gas film.

The Type 285 safely seals liquid nitrogen and works with site-based and road tanker cryogenic pumps to meet the safety standards for liquid oxygen.

Pressure rises as gas is forced towards the closed groove ends, creating a cushion that separates the sealing faces. This lack of contact virtually eliminates the problems of dry-running and face wear, long associated with conventional contacting seals.

It prevents seal face damage from solids or crystallising chemicals while improving resilience to poor lubricity, a notable issue when managing sodium hydroxide, sulfuric acid and polymerising fluids.

USP: Going forward

The combined benefit is to extend MTBR by ensuring seals last longer, require less downtime and reduce the maintenance burden – tangible improvements that support operational efficiency today.

However, protecting the planet's resources requires world-changing engineering solutions to meet the future needs of the energy and process industries.

In our next blog, we explore the environmental and operational benefits of USP. We showcase customer success stories where USP has reduced downtime and improved reliability and environmental compliance for those working with caustics and VOCs.

Catch up with the previous blogs in the series here.