Accelerating Decarbonization: Seal Design Best Practices for CCUS in Ammonia Applications

The ammonia industry has the potential to significantly lower global carbon emissions by transitioning away from its reliance on fossil fuels. Ammonia production is energy-intensive and accounts for nearly two percent of the world’s CO2 emissions annually.

Worldwide demand for ammonia will grow in the coming years, as it’s a base component of nitrogen fertilizers. Decarbonizing the ammonia industry will be necessary for meeting Net Zero Emissions by 2050 and other sustainability goals.

Carbon capture, utilization and storage (CCUS) technology that prevents carbon from entering the atmosphere is a promising pathway for accelerating emissions reduction efforts throughout the ammonia supply chain. However, handling CO2 can be challenging.

With proper design considerations, sealing solutions can help manage CO2 safely and efficiently, enabling the decarbonization of the ammonia industry through CCUS.

Ammonia’s Role in Reducing CO2 Emissions

The basic process for producing ammonia is simple—it involves combining just two elements, hydrogen (H2) and nitrogen (N2), to create ammonia (NH3). The most extensive and well-known use of ammonia is in agricultural nitrogen fertilizers, which accounts for 80% of ammonia produced worldwide. Beyond fertilizer, ammonia is used for manufacturing textiles, plastics and as a refrigerant.

As a commodity in the global marketplace, infrastructure for ammonia already exists. John Crane is active in the value chain with a portfolio of experience and market-ready solutions for filtration, as well as application-specific compressor and pump sealing technologies, and power transmission couplings.

Ammonia is incredibly useful today, and it could be even more valuable in the near future. When burned as a fuel, NH3 does not produce CO2; the power industry is currently exploring applications around this fact to accelerate decarbonization. Innovations include “co-firing,” which mixes ammonia with coal to fuel power plants.

Co-firing isn’t a perfect solution, as it still produces harmful emissions. However, it’s a way to reduce carbon emissions until other alternatives are available. Although co-firing is in its initial stages, John Crane is already involved in co-fired ammonia power projects. We leverage our sealing expertise to develop functional solutions that minimize leakage and maximize process reliability.

In addition to applications where it is used as a fuel, ammonia is also a hydrogen carrier that could smooth the way for an energy transition wherein fossil fuels are phased out in favor of emissions-free hydrogen.

Cleary ammonia has significant potential, considering its criticality in the agricultural sector and its future as a clean energy carrier. Consequently, finding a way to decarbonize ammonia production is important to achieving net zero goals.

Decarbonizing Ammonia Production with CCUS

Although the ammonia industry is moving toward net zero-emissions, today’s technology does not support enough emissions-free production to meet global demand; more innovation and capital investment are required. However, deploying a proven process such as CCUS could accelerate decarbonization.

There are two opportunities to capture carbon during ammonia production:

- During steam methane reforming (SMR): Where hydrogen is generated for creating ammonia.

- When combusting fossil fuels: This step produces the heat needed to combine nitrogen and hydrogen into ammonia.

John Crane has decades of experience with carbon capture applications. The facilities we support comprise approximately 50% of the world’s CCUS sites, and our solutions are found throughout the ammonia value chain, including:

Given that CCUS initiatives are already proving effective in sequestering carbon, the sealing technologies that enable CO2 capture should be prioritized in terms of policy and research.

CCUS Seal Design Considerations

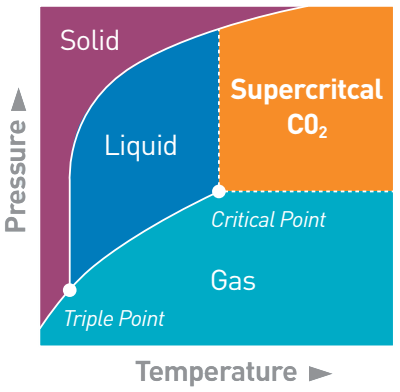

Handling CO2 can be challenging because there’s a critical point where it easily exists in multiple phases, exhibiting solid, liquid or gas properties.

CO2 in a supercritical state (at a pressure and temperature above its critical point) is complicated to handle as it exhibits gas and fluid properties. Also, if the temperature drops, it may change into a solid (i.e., dry ice).

Designing a sealing solution for CO2 requires anticipating and predicting density adjustments to manage phase change. Keeping a steady phase ensures the effectiveness of the seal and CCUS process.

Beyond CO2 specific considerations, a sealing solution must also be comprehensive, taking into account:

- Plant environment. Solutions should take into account handling temperatures as they can lead to dense phase CO2 that exists in multiple phases.

- Plant operations. Scrutinize the entire system for influence on pressure and temperature; even a narrow shift can trigger abrupt density changes that are extremely difficult to accommodate.

- Equipment type. Machinery brands and models that are identical from an operations standpoint must be evaluated from a rotational sealing perspective when dealing with supercritical CO2.

Process and equipment characteristics affect the handling of CO2, such as shaft sizes, rotational speeds, pressures and dimensions. These specifics impact seal design.

John Crane’s CO2 Sealing Solutions

With nearly three decades at the forefront of CCUS innovation, John Crane has supported CCUS projects across the globe. Approximately 80% of the world’s CO2 injected underground utilizes John Crane dry gas seals.

Process Modeling and Advanced Dry Gas Seal Design

CCUS seal design starts with gathering all the necessary information and employing modeling software to find the best solution. A successful model includes not just process specifics but also data about the equipment within the process where the seal will operate. Specificity is the linchpin of effective modeling, as each customer’s CCUS application differs.

Accurate phase prediction is part of CO2 management, as is maintaining a steady temperature to prevent carbon dioxide from shifting phase. The seal's effectiveness will be severely compromised if the CO2 inside the dry gas seal encounters thermal instability and changes phase (for example, from a gas to a liquid).

Two primary sources of heat may lead to thermal instability:

- Heat from the process

- Heat generated from the rotation of the dry gas seal faces

John Crane designs strategically with this in mind. Employing a deep knowledge of fluid and thermodynamics, our engineers precisely calculate the heat generated by seal face rotation.

By adjusting the precise shape and depth of seal face grooves, engineers can manage the heat generated during dry gas seal operation to maintain the thermal stability of CO2 and thus avoid phase change at the point of sealing.

In the supercritical state, CO2 exhibits the properties of both a gas and a liquid. This case study describes how John Crane developed sealing solutions for the world’s first supercritical CO2 power cycle plant.

Controlling the heat aspect of CO2 handling using seal face design supports effective sealing. It also provides an opportunity to reduce CAPEX, as an operator can potentially avoid utilizing heating equipment to maintain CO2 in a consistent phase.

Asset Operation and Seal Monitoring

John Crane’s products, such as pump seals and power couplings, are used throughout the ammonia value chain. But our support extends even further to asset management solutions, which enable predictive maintenance to increase uptime and maximize efficiency.

Equally important, our sensing technology, John Crane Sense®, uses digital monitoring to track the condition of dry gas seals and other process equipment. Accessible remotely in real-time, John Crane Sense® provides insight into seal performance and remaining life, allowing operators to optimize maintenance and plan appropriately.

Equally important, our sensing technology, John Crane Sense®, uses digital monitoring to track the condition of dry gas seals and other process equipment. Accessible remotely in real-time, John Crane Sense® provides insight into seal performance and remaining life, allowing operators to optimize maintenance and plan appropriately.

Solutions for Emissions Reduction

Adding reliable dry gas seal technology to CCUS minimizes leakage and maximizes the decarbonization of ammonia production. Likewise, sealing throughout the entire ammonia value chain brings efficiency and reliability gains.

Improved Efficiency

Effective use of sealing technology increases overall process efficiency in several ways.

- Less downtime for maintenance

- Effective use of process resources

- Economical use of energy

Advanced sealing solutions can reduce or even eliminate the leakage of harmful greenhouse gas (GHG) emissions, environmentally hazardous feedstock and/or process fluids. Thus, proper sealing reduces environmental impact and advances decarbonization efforts at multiple stages in the ammonia production process.

Reliability Gains

A seal failure can render a compressor inoperable, causing downtime and wasting resources. Equipment shutdown and startup processes are energy-intense and require the allocation of maintenance personnel from other tasks.

Utilizing the appropriate seal technology supports the longevity of compressors and other rotating equipment. Long-lasting sealing solutions improve and maintain reliability, which in turn extends uptime and contributes to process sustainability.

Seal design must consider the process and its effects on seal performance as well as the equipment specifics for the location of a seal, as using a solution unsuited to an application’s environment potentially leads to premature failure.

Accelerate CCUS with John Crane

Ammonia is part of the global future, with production poised to increase in the coming decades. As a key component of nitrogen fertilizer, ammonia supports the food chain, and as a hydrogen carrier, it has the potential to help realize a carbon-free energy economy.

Reducing emissions with CCUS is essential to reaching the world’s net zero emissions goals. John Crane’s solutions support the decarbonization of the ammonia industry, and our extensive experience with CCUS projects involves supercritical CO2, SMR and storage applications. Our engineers have the deep expertise required to design sealing solutions for reliable carbon capture, utilization and storage.

Explore John Crane’s sealing solutions for CCUS.