What is Melt Filtration

October 11, 2022

5 Minute Read

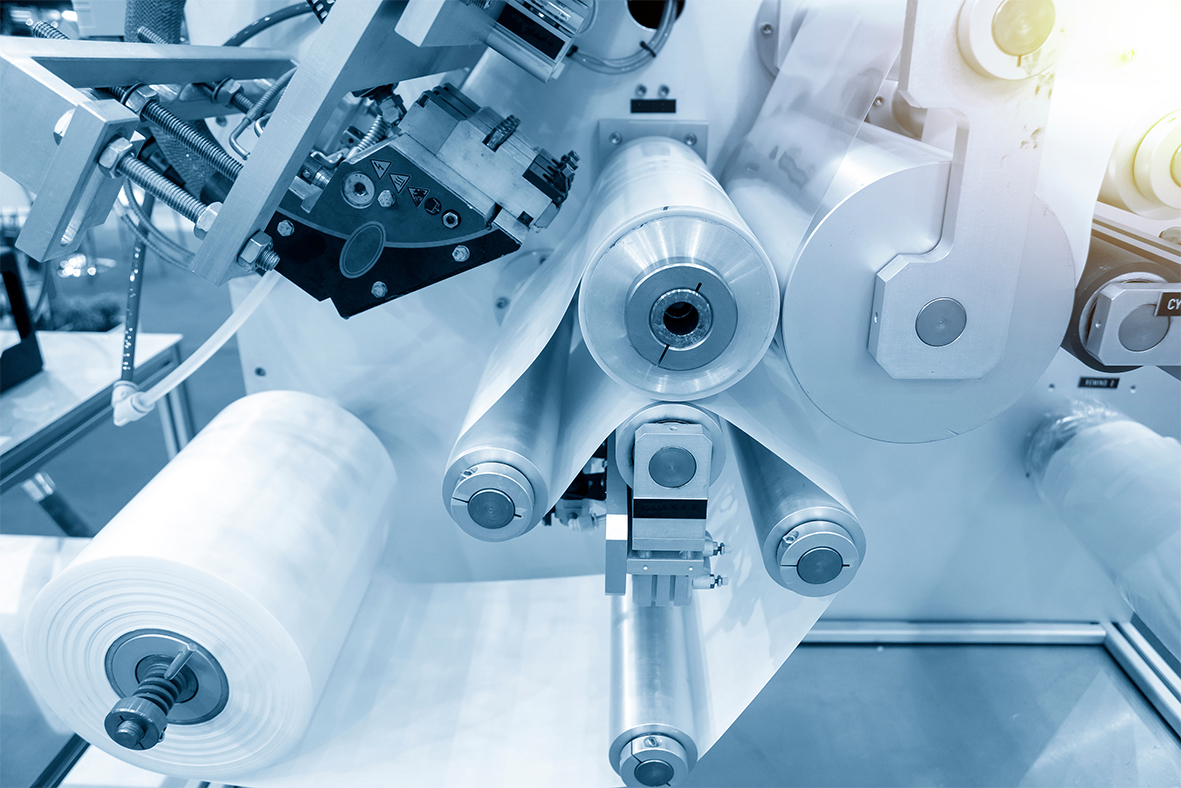

Why melt filtration is important for molten plastic

The use of melt filters in processing molten plastics (recycled and virgin) is essential. If the filtration process is not performed sufficiently, then a quality product can’t be produced.

What is a melt filter? The short answer, it removes contaminants from molten plastics. Melt filters are within high-pressure and high-temperature production processes to clean plastic melts of gels, degenerated material and debris.

The power of melt filtration

A high-performing melt filter is needed to provide continuous filtration to combat many challenges. Melt-filtration technology is typically used in instances where:

- the demand for a high-quality product can’t be achieved without filtration

- production can be stopped by unfiltered contaminants disrupting the process leading to excess production waste and process downtime

- long onstream life is required to maximize process line profitability

To produce a high-quality product, the right melt filtration technology should be chosen to gain these benefits:

- Reduce contaminants and impurities

- Improve the reliability and efficiency of the process

- Increase production output and uptime

John Crane’s Seebach® melt filters are applicable for multiple polymer production processes from pilot-single candle filters between 0.25 m² to 0.75 m² to multiple candle, duplex systems with changeover for continuous operation and filtration areas of up to 100 m². Learn more about our melt filters.