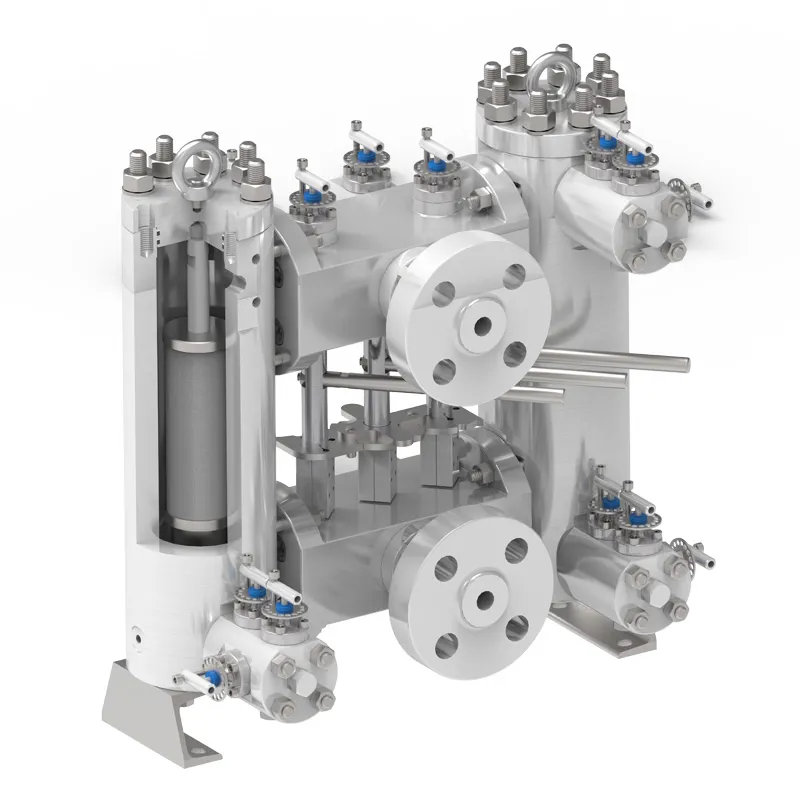

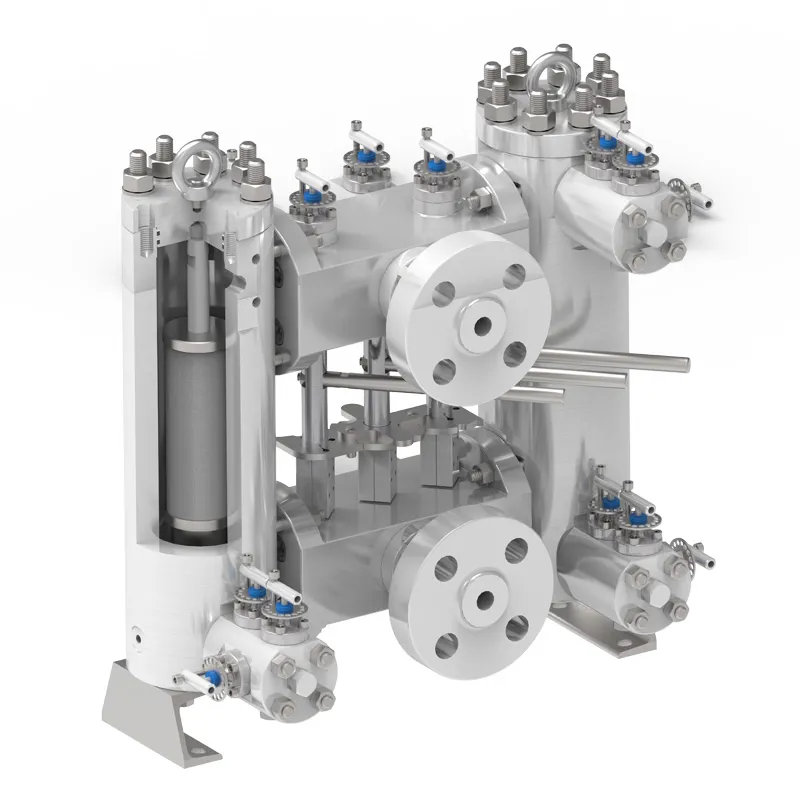

Duplex FCF Fuel Gas Filter

Filtration Solutions for Boil-Off Gas Management

John Crane’s Indufil® FCF filters efficiently remove oil and particle contaminants, ensuring enhanced reliability and optimal performance of boil-off gas (BOG) management systems on LNG, LPG and other gases. John Crane’s FCF series Filtration Systems are available in single and duplex configuration, in stainless steel as a standard and in higher alloys. Compliance with marine classification societies such as ABS, BV, DNV, LR, Class NK, CCS.

Our advanced filtration systems not only meet stringent cleanliness standards for contaminants of 1 micron and smaller at particulate efficiencies of 99.9%, but also deliver exceptional coalescing performance down to 0.005 ppm (w), all within a smaller footprint.

Recommended for You

Features

- Compact duplex configuration for continuous operation with a non-welded bolted design

- Coalescing and particle filtration

- Excess liquid removal by integrated pre-separation

- Filter contaminants of 1 micron and smaller at particulate efficiencies of 99.9%

- Coalescing performance down to 0.005 ppm (w)

- Compact design minimising footprint

- Interlinked transfer valves with bolted construction and providing a safe and zero-leak operation both to atmosphere and between the pressure vessels

- Both transfer valve (Class A) and needle valve (Class B) compliant to ISO 15848 (Fugitive Emission)

- Bolted top cover construction allowing an easy and clean filter element change out

- Integrated instrumentation available

- Heat tracing and/or insulation

Parameters

- Standard Materials:

- Stainless steel 316(L)

Higher-grade materials such as UNS S31803, UNS S32750 and Inconel alloys. - Temperature Limits:

- -94°F to 428°F/-70°C to 220°C

- Pressure Limits

- 5990 psi(g)/413 bar(g) for standard 316 (L)

- Certified to:

- Pressure Vessel codes: ASME VIII Div. 1, PED

Explosion safety: ATEX Ex II 2G, IECEx Ex II

Marine & Offshore: ABS, BV, DNV, LR, Class NK, CCS

Optional: U-stamp, TR-CU, ML, Dosh, NR13, ARH, AS1210, CRN - Maximum flow rate:

- Sizing in accordance with API 692 or alternatively based on maximum gas coalescing velocity

- Filter Efficiency

- Removal of liquids from gas down to 0.005 ppm (w)

Recommended Applications

- High pressure gas applications