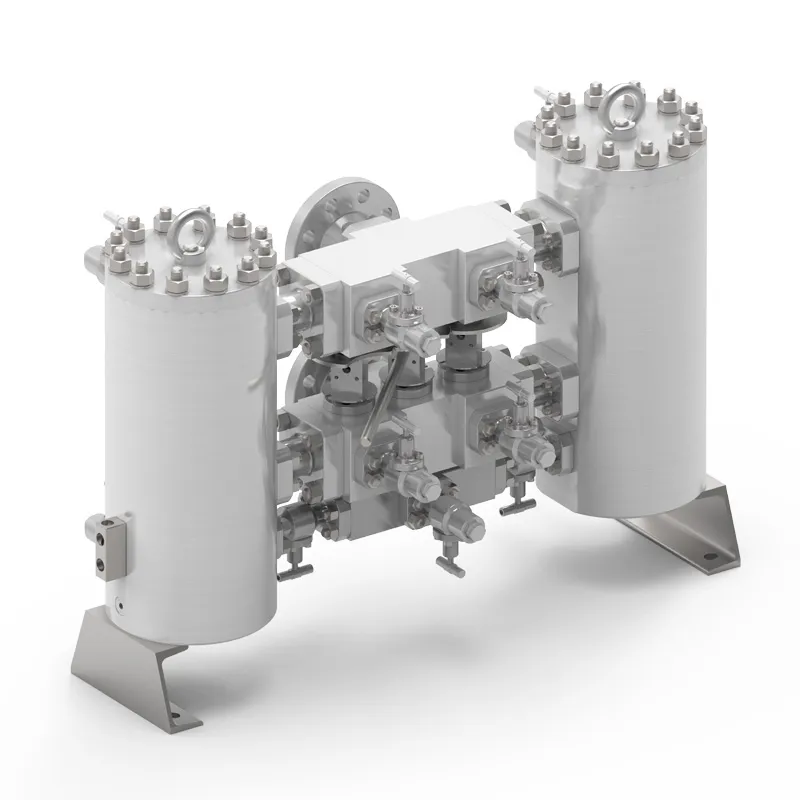

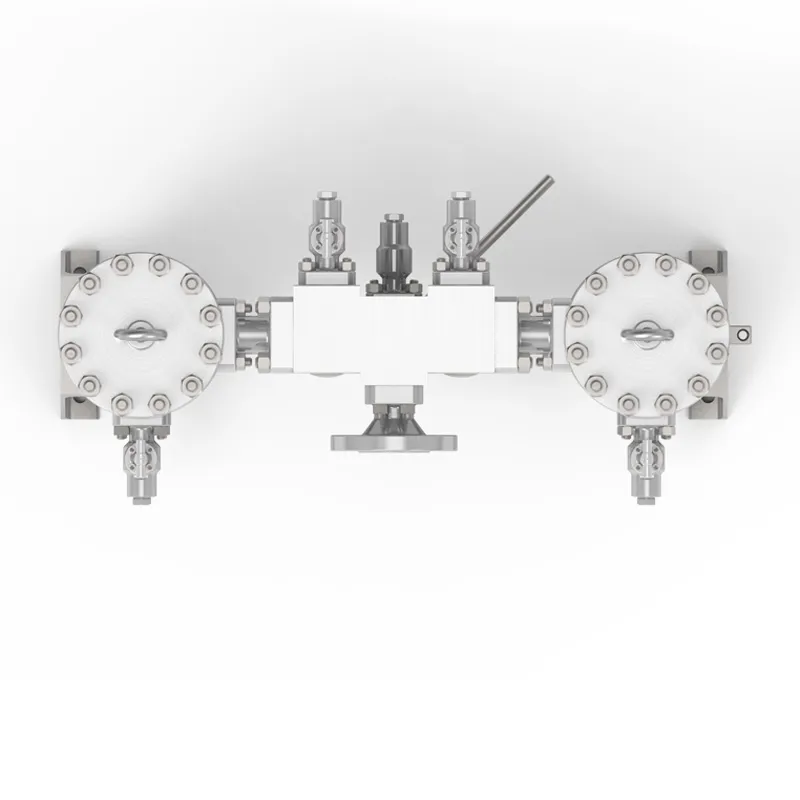

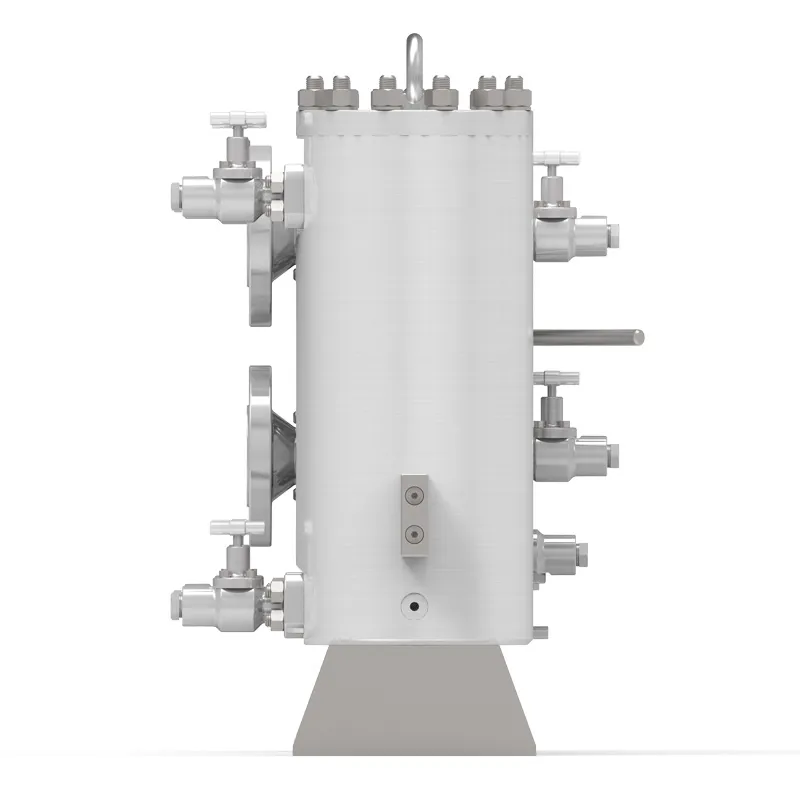

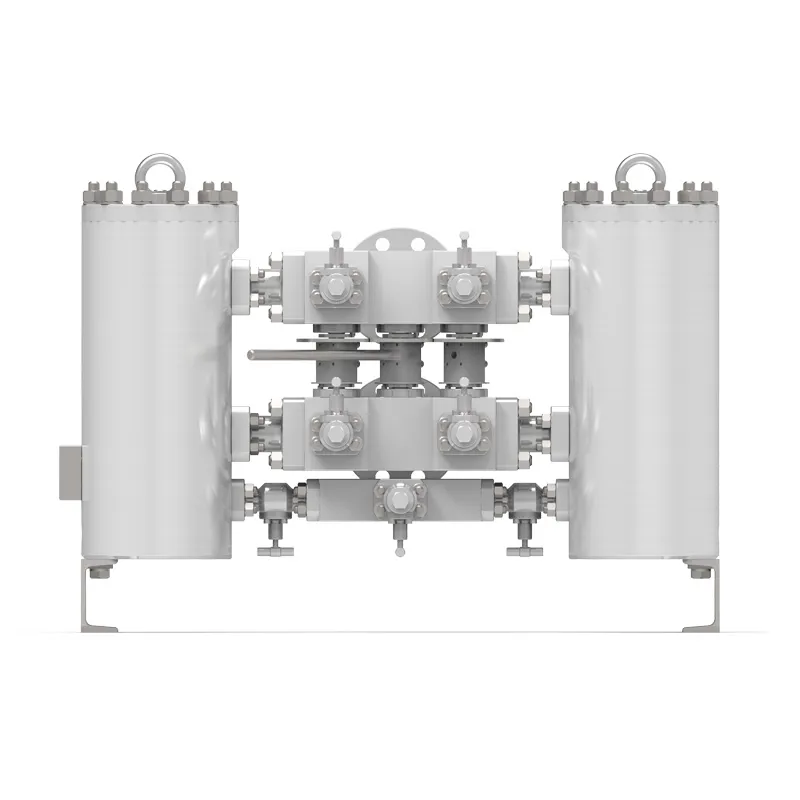

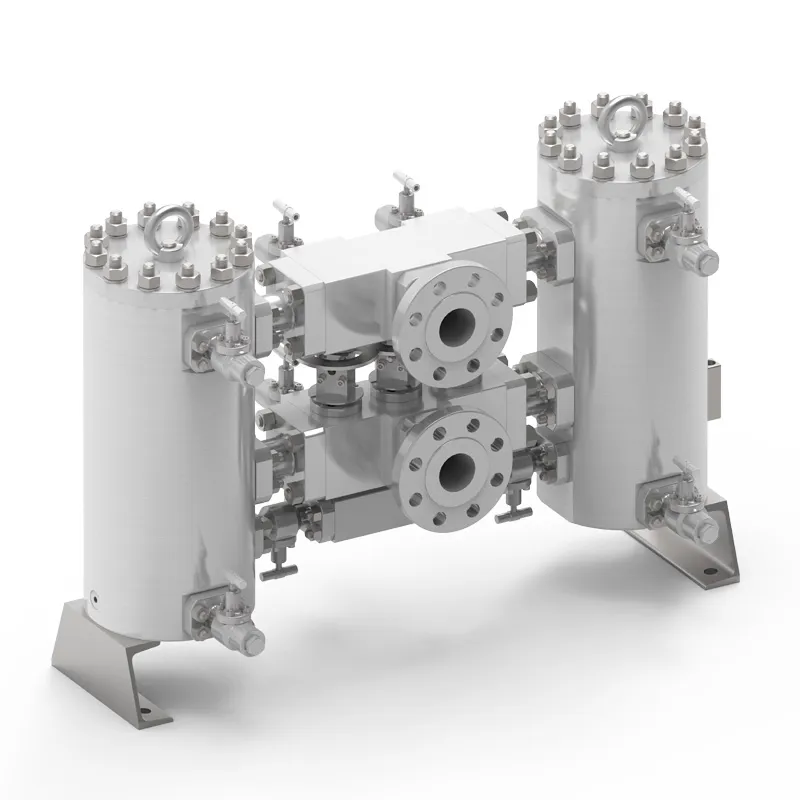

Double Block and Bleed (DBB) Fuel Filter

Filtration for Fuel Conditioning and Supply

John Crane’s Double block and bleed (DBB) Filters are installed on fuel supply systems of dual fuel marine vessels. The DBB design of the filter allows containment of harmful and toxic fuels such as ammonia and methanol and guarantees a high level of safety. John Crane’s Indufil® DBB valve is designed to provide leak-free and continuous operation. Filters in DBB configuration allow adequate, uninterrupted filtration of fuel when changing to the standby filter unit. Compliance with marine classification societies such as ABS, BV, DNV, LR, Class NK, CCS.

John Crane’s Indufil elements remove particle contamination and maximise reliable operation of the machine.

John Crane's Indufil modular building principle — using machined parts from forgings — offers high flexibility and a compact design that provides plug-and-play solutions for upgrades.

Recommended for You

Features

- Double block and bleed valve

- Marine classification

- Compact design

- Filtration fineness down to 3 micron and efficiencies up to 99.9% (ß>1000)

- Plug-and-play filtration unit

- Inlet and outlet sizes up to 6" internal diameter and guaranteed leak-free transfer valves

- Integrated instrumentation available

Parameters

- Standard Materials:

- Stainless steel 316(L) Higher-grade materials such as UNS S 31803, UNS S32750 and Inconel alloys.

- Temperature Limits:

- -94°F to 428°F/-70°C to 220°C

- Pressure Limits:

- 5990 psi(g)/413 bar(g) for standard 316 (L)

- Certified to:

- Pressure Vessel codes: ASME VIII Div. 1, PED

Explosion safety: ATEX Ex II 2G, IECEx Ex II

Marine & Offshore: ABS, BV, DNV, LR, Class NK, CCS

Optional: U-stamp, TR-CU, ML, Dosh, NR13, ARH, AS1210, CRN - Maximum flow rate:

- Sizing based on maximum pressure drop and dirt holding capacity required

Recommended Applications

Low flash point fuel supply system

- Methanol

- Ammonia

- LPG

- Ethane

- Other liquid fuels