John Crane at TPS in Houston, 2025

Get ready to optimise your plant's operations for maximum performance. Visit us at Booth 2801.

Houston, Texas

Let’s shape the future of sealing for the energy and processing industry.

Tuesday, September 16

Mechanical Seals Short Course and Discussion Group (10:30 a.m.–12:00 p.m., Room 362A) Brian Kalfrin will share guidance on choosing mechanical seals, optimising performance, resolving issues and staying current with API 682 updates.

PFAS – Potential Impacts to the Sealing Industry (2:00–3:00 p.m., Room 370C) Jim Wasser, Denise Lee and Brian Kalfrin explore PFAS through a science-based lens, examining its role in sealing and outlining alternative approaches for emissions and leakage management.

Bridging Energy Demand and Sustainability through Rotating Equipment (8:00am). Nico Schmaeling, John Crane’s Senior Director of Auxiliary Product Portfolio and New Energy, will present the keynote address exploring how modern rotating equipment delivers higher efficiency, reduced emissions, and safer operation while meeting rising energy demand. This strategic session highlights how productivity and sustainability can progress together across global energy markets.

Wednesday, September 17

Low Emissions Sealing Experience Gained Over the Last 30 Years (10:30 a.m.–12:00 p.m., Room 370C) Jim Wasser and Brian Kalfrin will share insights from decades of innovation, spanning material and design advancements to sustainable practices that enable operators to meet environmental goals without sacrificing performance.

Dry Gas Seals for Compressors Short Course and Discussion Group (2:00–3:30 p.m., Room 360C) Vladimir Bakalchuk, Joe Delrahim and Chris Auzenne will lead an interactive session covering operating characteristics, system configurations, troubleshooting and best practices proven in the field.

Thursday, September 18

Nova Caustic Pumps Up Stream Pumping (8:30–9:00 a.m., Room 370C) Doron Or presents a solution that lowers operating costs, reduces water use and delivers over four years of mean time between repair in demanding caustic service.

Improved Reliability with New High Temperature Gas Seal Technology (9:30–10:00 a.m., Room 370C) Rob McManus and Jamie Cetrone will share how a dual pressurised gas-lubricated seal improved long-term performance in hot hydrocarbon service.

Learn from our experts at TPS

TPS is the industry’s primary event, and John Crane is sending our best people. Seasoned engineers and subject matter experts will be sharing decades' worth of professional expertise and lived experience. Check out the full list of tutorials, discussions, workshops and lectures.

View the full TPS schedule.

Tuesday, September 16

Wednesday, September 17

Thursday, September 18

Our Solutions Suite for TPS 2025

John Crane Sense®

Flexible, data-driven monitoring for always-on operations.

Remotely monitor seals and rotating equipment in near real-time to detect and correct potential problems.

Type 2874HTC

· A metal bellows mechanical seal for handling process fluids up to 425°C (800°F).

Its non-contacting gas-lubricated design eliminates the need for wet support systems, simplifying operations and enhancing long-term reliability.

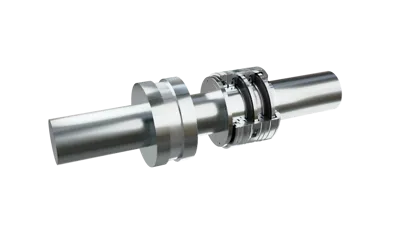

Type 93AX

Improved productivity for mission-critical turbomachinery applications.

Our new coaxial separation seal delivers a safer, more reliable and efficient solution.

Type SB2/Type SB2A

A dual-cartridge, double-balanced mechanical seal built for demanding slurry duties.

Handles hazardous and abrasive fluids with up to 40% solids by weight and 8 Mohs of hardness.

Type 8628VL

A fully non-contacting mechanical seal for ethane and ethylene pipeline operators.

Multiphase seal face lubrication helps extend MTBR to up to 48 months and even longer, reducing costs and improving uptime.

Bring your challenges to TPS. Let's talk solutions.

Whether you need to improve outcomes and efficiency, reduce waste and emissions, or technical support to do both, visit us at Booth 2801. John Crane experts are on hand to help.

Reduce emissions and ensure greater safety

Our advanced dry gas seals are designed to minimise fugitive emissions into the atmosphere, making your plant safer for operators, more efficient and protecting the environment.

Advanced flow-solutions for the oil and gas industry

As a global leader in advanced mechanical seals, filtration, and couplings for all oil and gas applications, we're enabling the entire value chain, upstream to downstream and LNG to petrochemicals.

Support when and where you need it

Our leading global sealing support network includes world–class local expertise wherever our customers operate to minimise downtime and maximise operational efficiency.