USP 技术的价值和优势

John Crane 独家制造的非接触式 USP 密封面技术借鉴了气体密封设计,在液体密封技术上取得了突破。传统密封的典型平均修复间隔时间 (MTBR) 为三年,而 USP 密封则超过五年。以下是好处:

延长了平均修复间隔时间 (MTBR)

几乎不需要冷却冲洗用水*

节能

零排放

*取决于应用要求

使用我们新的估算工具计算您的水和二氧化碳排放节约量

USP 密封面技术有助于克服最严峻的密封挑战。该技术可提高密封和泵的可靠性,防止意外停机,并降低各种恶劣工况下的运营成本,例如:

该技术还适用于采用挑战性工艺流体的各种加工工业,例如:

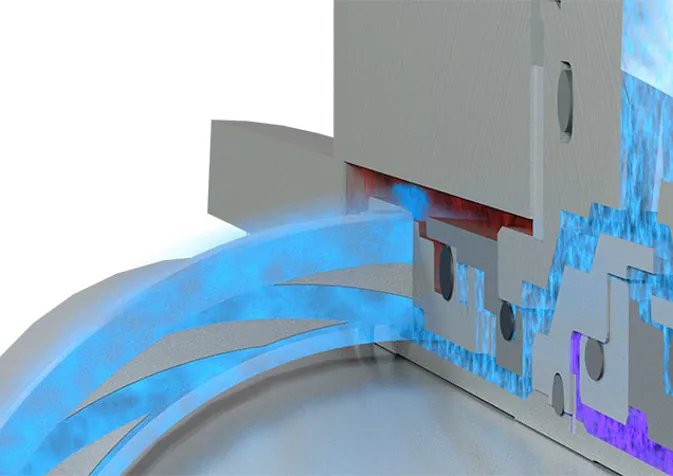

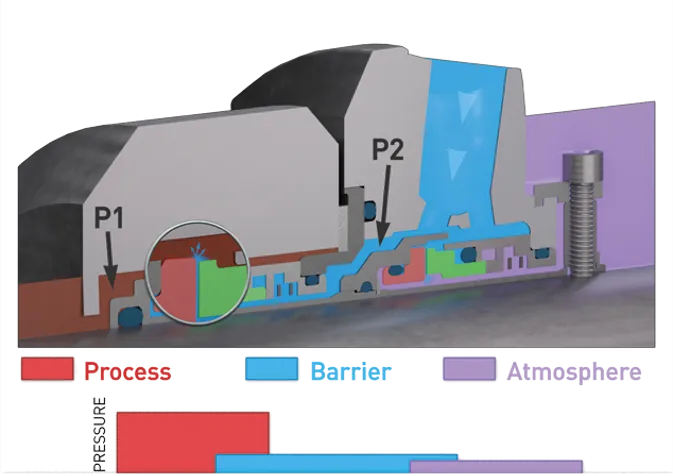

John Crane 解决方案的基本概念是,用小容量高压“泵”,即 USP 密封取代传统密封。该泵沿着通常由机械密封面密封的路径将少量隔离液泵入介质侧。由于介质侧的压力高于隔离液,该密封被称为泵的“上游”。

机械密封需要密封面之间有一个很窄的间隙,以便润滑膜能够起作用;该间隙也必须经过优化以消除泄漏。工艺流体中的碎屑会产生沉积物,损坏密封面并导致挂起。这就是 USP 起作用的地方 — 它延长了泵密封的使用寿命和平均维修间隔时间 (MTBR)。

采用上游泵送密封面技术的机械密封有着与传统双机械密封不同的支持系统要求。可以为我们的标准上游泵送密封提供标准化的支持系统。使用这些系统之一可无需设计定制系统,以节省成本,简化操作,并最大限度地减少空间需求。有关 GS USP–R 和 GS USP–D 的更多信息

使用 USP,冷却所需的水量几乎为零。与传统密封方法相比,能耗也显著降低。

John Crane 支持贵公司的二氧化碳减排战略。一个泵增加一个 John Crane USP 密封,每年即可少排放 12.4 吨的二氧化碳。

| 密封的平均修复间隔时间 (MTBR) | 年 用水量 | 年 用电量 | 平均运行 成本/年* | |

|---|---|---|---|---|

| 传统密封 | 3 年 | 4,200 立方米 (920,000 加仑) | 19,500 千瓦时 | = 4,200 美元 |

| 带 GS USP 支持系统的 USP 密封 | 5 年以上 | 4.9 立方米 (1,070 加仑) | 1,970 千瓦时 | = 290 美元 |

| 净效果 | 2 年 额外的 MTBR | 4,195 立方米 (918,930 加仑) 节水量 | 17,530 kWh 节电量 | = 3,910 美元 净节省成本 |

*假设水费为每立方米 0.35 美元。因地理位置和水源的不同,水费差异极大。

*电费按每 kWh 0.142 美元计算,这是 2022 年第 3 季度美国的典型平均电价。

注:本例中不包括额外节省的维护成本,例如加满储罐的成本、密封翻新成本或设备

停机成本,但这些成本节省也会实现。

上游泵送 (USP) 是 John Crane 独有的密封面技术,在隔离液中运行的双端面机械密封的内侧密封中增加了非接触式干气密封中常见的螺旋槽。螺旋槽的增加带来了独特的运行优势,包括提高可靠性,几乎无需冷却和冲洗用水,并降低了功耗。

采用 USP 的机械密封有着与传统双端面机械密封不同的支持系统要求。可以为我们的标准 USP 密封提供标准化的支持系统。使用这些系统之一可无需设计定制系统,以节省成本,简化操作,并最大限度地减少空间需求。

该系统有两种不同型号:包含储罐的 GS USP-R 和直接连接供水系统的 GS USP-D。使用哪个系统取决于多个变量,包括流体类型、隔离液压力和流体质量。填写以下标准,以确定适合您的应用的最佳支持系统。

全球标准化上游泵送支持系统 (GS USP) 是基于 John Crane 的流体控制专业知识和卓越工程能力的优化预工程设计。GS USP 是一种最佳实践解决方案,可显著缩短规格审查和交付计划,提供低压隔离水,以实现最佳的机械密封性能和可靠性。

全球标准化上游泵送支持系统 (GS USP) 是基于 John Crane 的流体控制专业知识和卓越工程能力的优化预工程设计。GS USP 是一种最佳实践解决方案,可显著缩短规格审查和交付计划,提供非加压隔离水,以实现最佳的机械密封性能和可靠性。

全球标准化上游泵送支持系统 (GS USP) 是基于 John Crane 的流体控制专业知识和卓越工程能力的优化预工程设计。GS USP 是一种最佳实践解决方案,可显著缩短规格审查和交付计划,提供非加压隔离水,以实现最佳的机械密封性能和可靠性。

全球标准化上游泵送支持系统 (GS USP) 是基于 John Crane 的流体控制专业知识和卓越工程能力的优化预工程设计。GS USP 是一种最佳实践解决方案,可显著缩短规格审查和交付计划,提供非加压隔离水,以实现最佳的机械密封性能和可靠性。