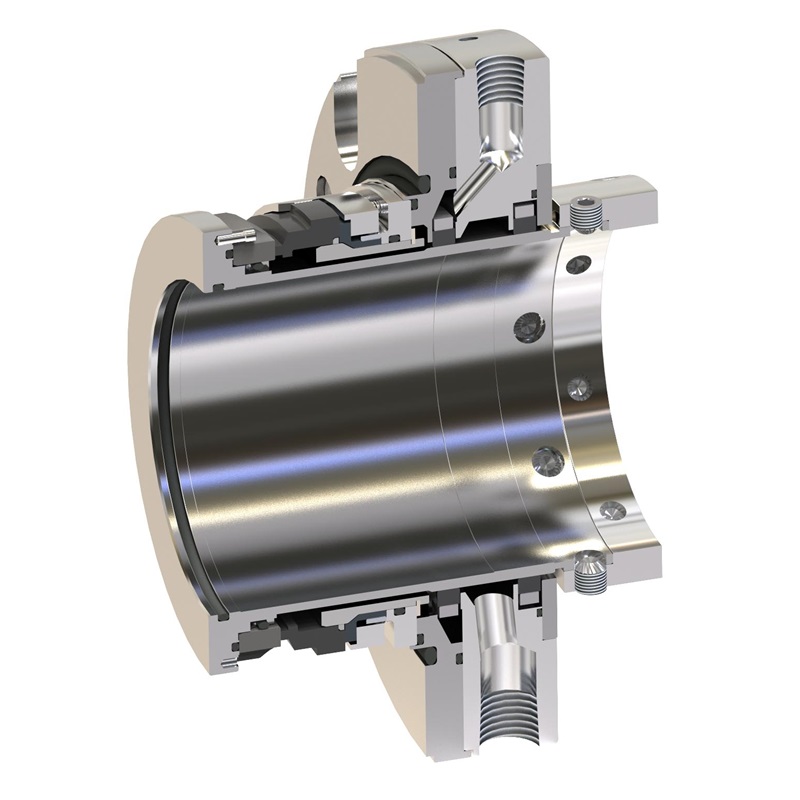

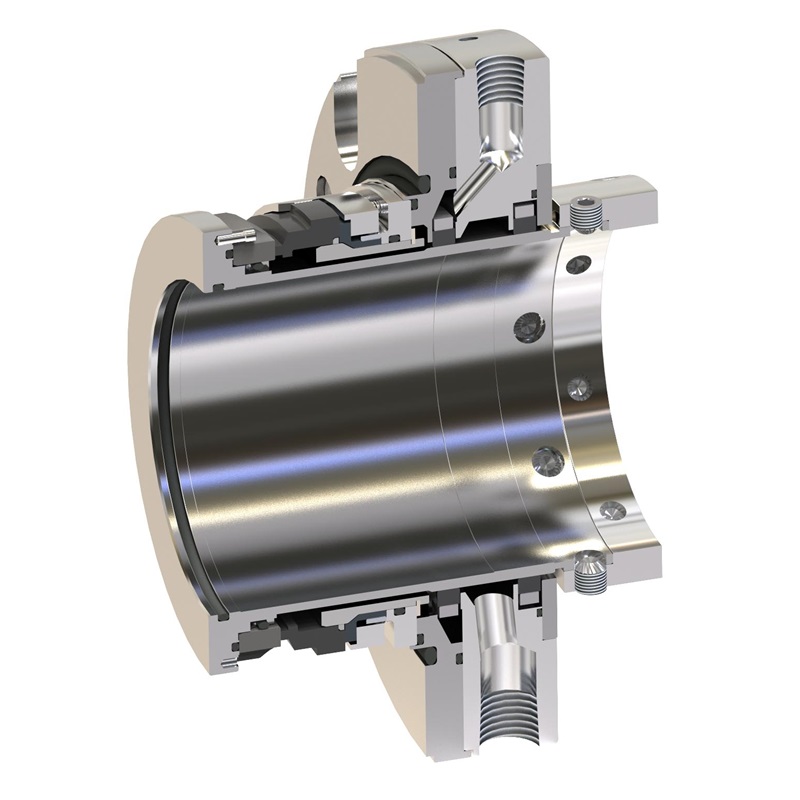

Type 8648VRS

Single and Dual Non-pusher Elastomer Seal

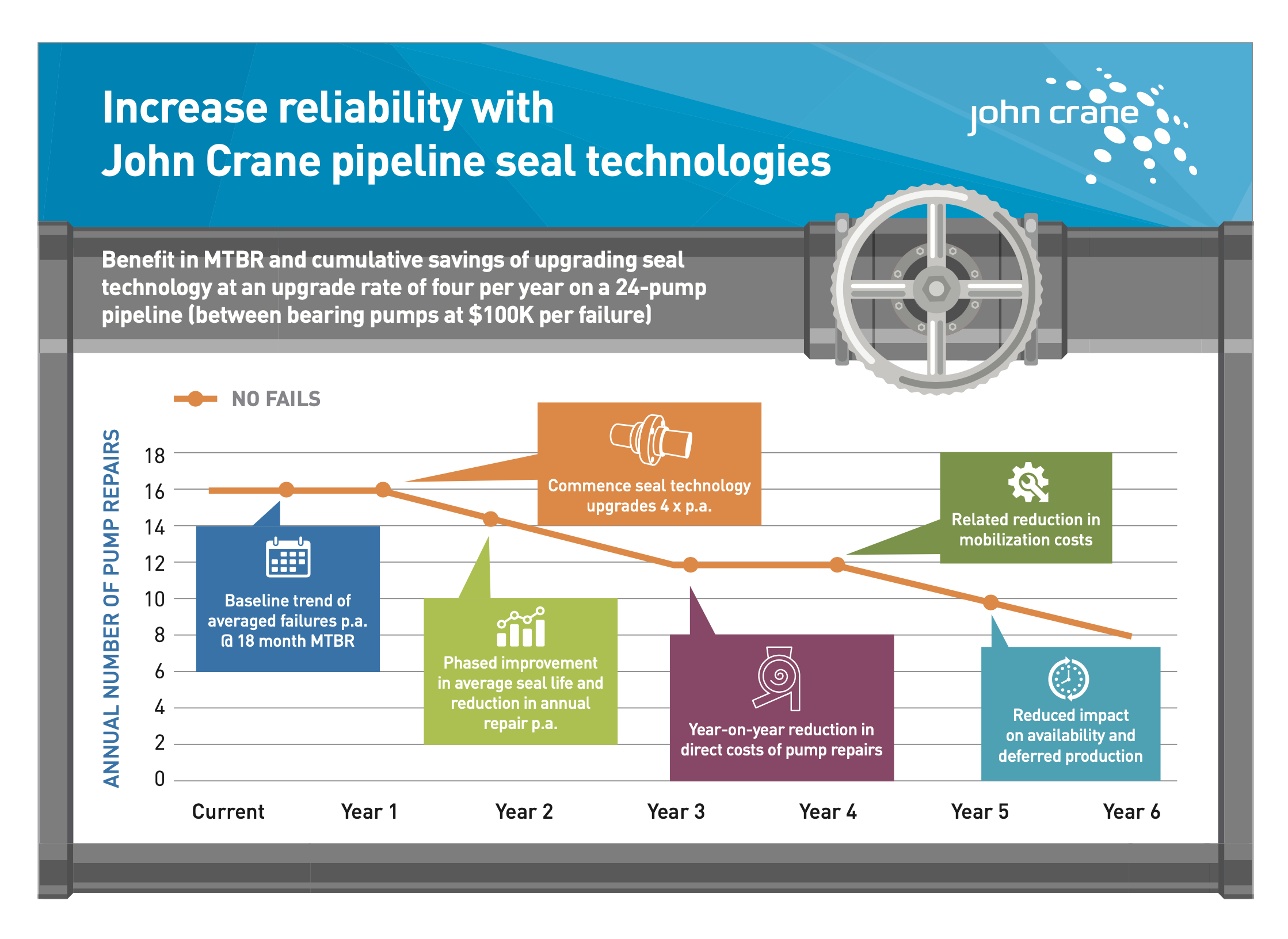

Type 8648VRS is a standardized non-pusher elastomer mechanical seal using patented technology, designed specifically for difficult hydrocarbon oil pipeline applications. It is designed specifically with a focus on meeting the demanding requirements of pipeline pumping station duties. Available as a single, dual pressurized or dual unpressurized arrangement, without outboard seals also incorporating the same non-pusher technology, the seal can be configured to suit both the operator and pipeline needs.

为你推荐

产品信息

The main risk of seal failure in these applications is due to the numerous problems associated with the secondary dynamic O-ring, potentially resulting in hang up, fretting or stub sleeve wear. The unique design of the Type 8648VRS completely eliminates these common problems.

By allowing operation without the potential for secondary seal problems, the Type 8648VRS provides longevity and reliability even in the most difficult pipeline applications.

Features

- California Residents: PROPOSITION 65 WARNING

- Unique patented secondary seal technology prevents wear to the sealing diameter and prevents secondary seal hang up

- Non-compressible flexible elastomer bellows avoids fretting under pump shuttling

- Robust Ear drive — primary ring incorporates optimized ear drive design for increased drive torque capability

- Balanced design – balanced construction, including anti-extrusion ring, permits use in the most demanding high-pressure pipeline duties

- Rotating mating ring design — enhances cooling and permits use at higher shaft speeds

- Premium seal face materials — permits sealing of difficult services at high operating pressures

- High-shore elastomer for lack of deformation and robust construction

- Axially compact and easy to install seal head assembly

- Static reverse pressure capability on the inboard seal of the dual pressurized configuration

- Laser face grooved mating ring for use on flashing hydrocarbons

Parameters

- Temperature Limits

- -4°F to 400°F / -20°C to 204°C

- Speed Limits

- 5,000 fpm/25.3 m/s (Crude)

6,000fpm/31.5m/s (Non-Crude) - Pressure

- Dynamic Pressure (Single Seal): Up to 1,450 psi(g)/100 bar(g) (Crude)

Dynamic Pressure (Single Seal): Up to 1,300 psi(g)/90 bar(g) (Non-Crude)

Dynamic Pressure (Dual Seal): Up to 1,750 psi(g)/120 bar(g) (Crude)

Static Pressure: Up to 2,200 psi(g)/152 bar(g) (Crude)

Static Pressure: 2,000 psi(g)/138 bar(g) (Non-Crude)

Recommended Applications

- Pipeline Pumps