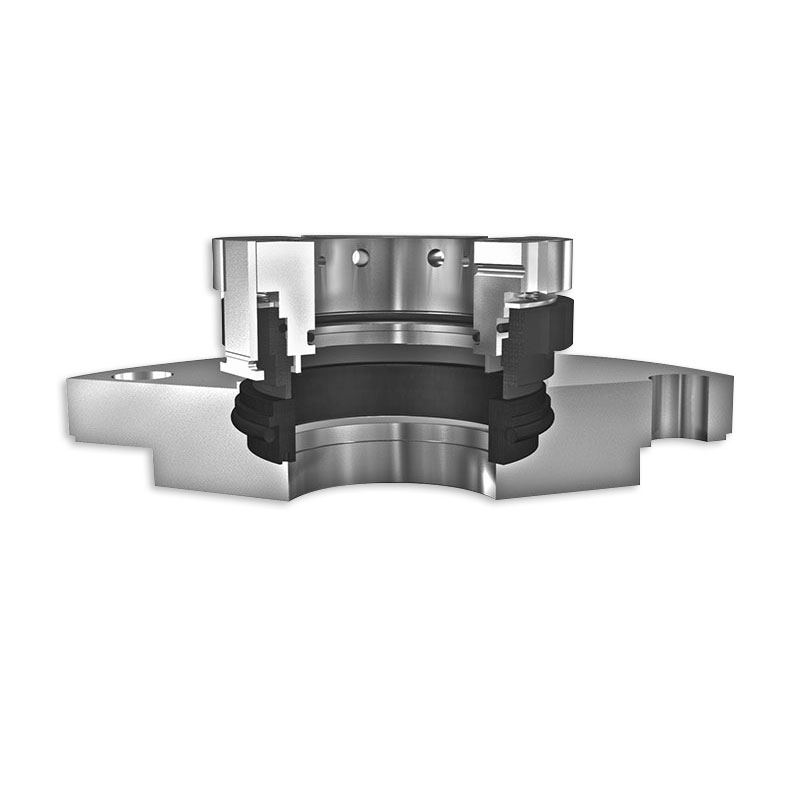

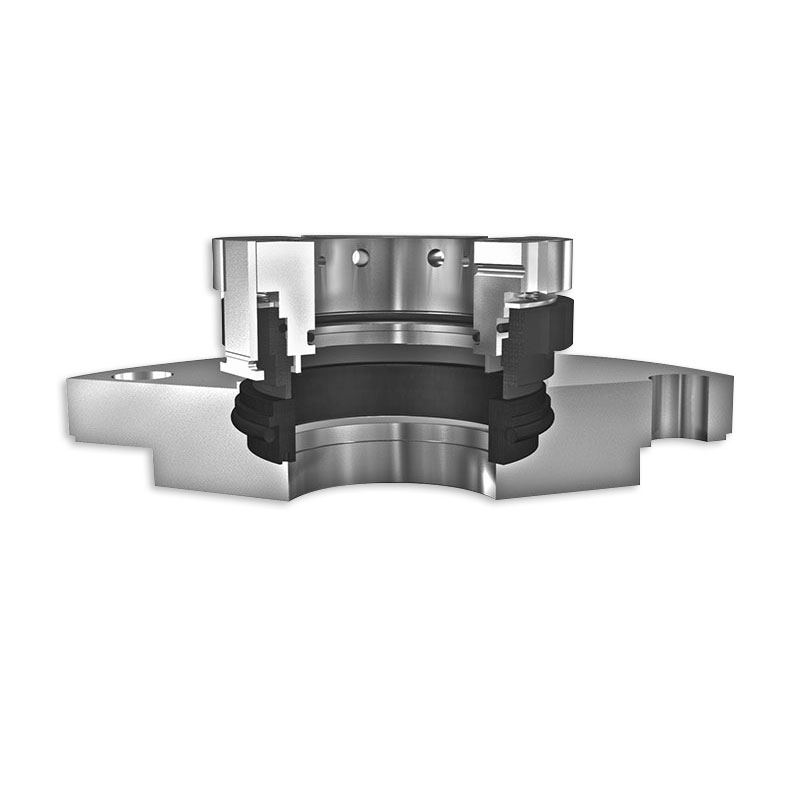

Type 32D

Single Dry-running Mixer and Agitator Seal Suitable for Explosive Atmospheres

Type 32 D vessel seals are outside-mounted, balanced single seals with self-lubricating seal faces. Neither external cooling, lubrication equipment nor a supply system is required. The design and material selection meets the needs of the pharmaceutical and chemical processing industries. The seals are excellent for low-duty mixing applications and operation in vacuum conditions. The seal can be supplied in component form consisting of spring-loaded face, driver retainer and mating ring, or pre-assembled on a flange. The flange version can be equipped with a debris well, enabling it to capture face wear particles, preventing the contamination of process fluid. Standard flange designs are available with dimensions to DIN 28138 Parts 1 and 3. Customized flanges available on request.

All versions are suitable for application in potentially explosive areas without any further control device. Certificates of conformity according to European Directive 2014/34/EU (ATEX) Cat. 1, 2 and 3 available on request. Depending on operating conditions and temperature class of the application, operating limits can be restricted.

Recommended for You

Features

- California Residents: PROPOSITION 65 WARNING

- Single O-ring mixer seal for top entry vessels.

- Outside-mounted, dual-balanced design.

- No external lubrication required.

- Reverse pressure design (applied for high pressure and vacuum).

- Robust T-bar drive mechanism for high-torque transmission.

- Mechanical wear indication.

- Standard sizes from 25mm to 125mm shaft diameter.

- Standard design options: component seal with standard flange (according to DIN); component seal with flange and debris well.

- Suitable for application in explosive areas. Certificates of conformity according to European Directive 2014/34/EU (ATEX) Cat. 1, 2 or 3 on request.

Parameters

- Temperature Limits

- -40°F to 300°F/-40°C to 150°C

- Pressure Limits

- Vacuum to 6 bar(g)

- Speed Limits

- Up to 800fpm/4m/s, depending on size and pressure

- Size Limits

- 25mm to 125mm

Recommended Applications

- Mixer and agitators

- Other rotating equipment