For more than 100 years, John Crane has equipped global process industries to meet mission-critical challenges. Our customers depend on John Crane to ensure their operations run efficiently and effectively. We deliver on that promise with technologies that maximize reliability, innovations that improve efficiency and services that enable a proven rapid response.

As pioneers of progress, we are committed to leveraging our legacy of technology leadership, innovative solutions and service excellence to help customers achieve their net-zero ambitions. We’re fully committed to supporting global efforts that address climate change and are taking concrete steps to reach net carbon neutrality by 2050. Building a sustainable future, today.

How can we help?

Get in touch

Popular links

How can we help?

New Energy

We power sustainability through scalable clean hydrogen, carbon capture, utilization and storage (CCUS) and greenhouse gas emission reduction technologies that safeguard the future of our planet and industry.

Products

Mechanical Seals

The scope of our mechanical seal product range far exceeds that of any other seal manufacturer. John Crane has the right product for any application — from small elastomer bellows seals used in millions of domestic water pumps and double mechanical seals that ensure maximum sealing safety to large, highly customized dry-running gas seals for mission-critical, high-speed turbo compressors.

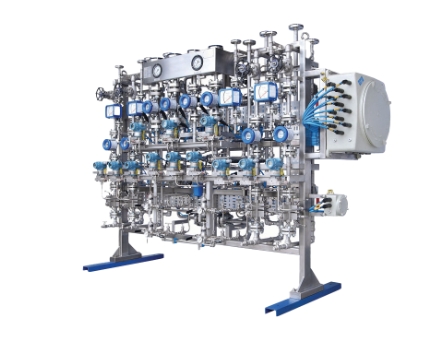

Seal Support Systems

The right seal support system is critical to promoting seal reliability and overall energy efficiency. John Crane customizes support systems to meet a variety of seal specifications, contributing to safe, cost-effective, reliable operations that reduce harmful environmental effects. Our support systems comply with constantly changing design codes and standards, equipping end users to meet increasingly stringent demands.

Seal Face Technologies

Our comprehensive suite of seal face technologies is designed to overcome rigorous sealing challenges, including limited seal face lubrication and severe-service duties that adversely affect reliability, operational costs and seal life. Designed by our engineering experts, John Crane’s face treatment options help your equipment power through low-lubricity and dry-running conditions by using advanced micromachined patterns and features. These innovations improve seal face lubrication to optimize the performance of rotating equipment in all process industries.

Power Transmission Couplings

For more than 50 years, John Crane’s flexible couplings have helped rotating equipment operate at optimum levels and with maximum availability. As a result, John Crane’s couplings have become the first choice of many of the world’s leading companies. Our policy of continuous innovation and product development ensures that we satisfy the changing demands of the market while fully complying with all relevant industry standards.

Equipment Filtration

John Crane offers a comprehensive range of filtration products to significantly reduce contamination and increase the efficiency of your operation. Our products are designed to work together in complex systems to ensure optimum filter performance. Patented filtration technologies provide filter elements that remove both liquids and solids within a single unit. Our replacement elements incorporate John Crane's patented design features, ensuring maximum filter performance.

Process Filtration

Your method of production often introduces contamination into your process, whether from imperfect ingredients, necessary reagents or process equipment. Delivering an end product free from impurity and contamination requires inhibiting filtering action.

Packing

Do you want to minimize leakage from your pumps in an effective manner? Operators and maintenance managers face this costly challenge on a daily basis. John Crane offers a wide selection of compression packing, automatic packing, floating packing and injectable packing materials. Learn more about our packing, which is equipped to handle the vast majority of sealing solutions across nearly all applications.

Services

We serve our customers through a combination of technical expertise and quick response times, supporting mission-critical operations across various process industries.

Careers

Our engineered solutions optimize the reliability and efficiency of our customers’ mission-critical equipment. If you’re interested in accelerating the new energy transition across the global process industries, you’ll fit right in.

Industries

Founded more than 100 years ago, John Crane has a long legacy of solving mission-critical energy and process industry challenges. Our world-changing products, solutions and services equip operations to navigate the new energy landscape without sacrificing the safety and reliability that earned John Crane its good name.

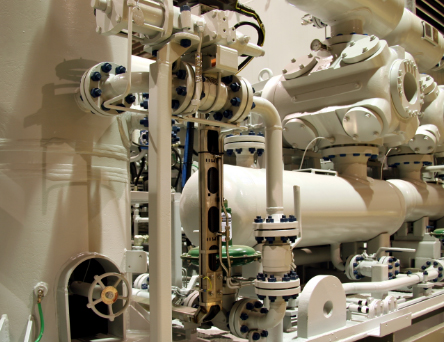

Oil and Gas

Reliability, safety and sustainability are all essential in oil and gas applications. John Crane offers a wide range of innovative services and applied engineering solutions to help highly regulated, mission-critical operations embrace the energy transition while achieving their operational goals.

Power Generation

John Crane’s depth and breadth of applied engineering expertise, product innovation and reliability services help plants of all types increase uptime, reduce emissions and improve efficiency in the new-energy era.

Chemical

With a wide range of complex equipment, the chemical industry faces key operational challenges — and it trusts John Crane to solve them. Our 200 global rapid-response facilities ensure that chemical industry customers are never far from service, repair or support.

Pharmaceutical

From clean-in-place components to batch documentation and certification of material integrity, John Crane provides pharmaceutical processing companies with the engineered components and services they need to stay ahead in a rapidly-changing industrial landscape.

Polymers

Polymerisation is the first basic step in plastics production. John Crane’s products, services and solutions help extend the life of polymer applications and increase production by limiting unplanned downtime, enhancing efficiency and identifying other key process improvements.

Mining and Minerals

With decades of experience serving the mining and minerals industries, John Crane understands the critical nature of maximizing equipment reliability, emissions reduction and performance in harsh environments.

Food and Beverage

To achieve optimal efficiency while meeting stringent health and safety standards, food and beverage industry plants and manufacturers must maintain a complicated balancing act. John Crane makes this manageable by engineering reliable, specialized components that improve productivity, enhance efficiency and eliminate contamination.

Pulp and Paper Processing

In the pulp and paper processing industry, efficiency and reliability are key. John Crane’s pioneering products, solutions and services help operators reduce the energy consumption and costs associated with critical processes.

Refrigeration Compression

From oil refineries to petrochemical plants, many mission-critical operations require refrigeration for temperature-specific processes. Trust John Crane to ensure every compressor seal and coupling maintains optimal performance and reliability.

Wastewater and Clean Water Management

Characterized by high volumes and abrasiveness, wastewater and clean water management poses significant challenges for supporting equipment design. Our cost-effective solutions reduce energy consumption and increase the efficiency of equipment used in all types of clean water and wastewater applications, from filtration to chlorination.

Solutions

We deliver groundbreaking solutions to help our customers lower the total cost of ownership, meet the latest environmental standards and leverage digital technologies to achieve key operational goals.