What is a Turbomachinery Service Engineer?

John Crane’s team of highly trained turbomachinery service engineers (TSE) travel globally to support compressor manufacturers and dry gas seal end-users on site. They implement dry gas seal change-outs, start-ups and other turbomachinery services during planned shutdowns and unplanned breakdowns in the infrequent event of a site emergency.

John Crane invests heavily in its team, through a structured and intensive training program. This program fast-tracks new engineers, via mentoring schemes with qualified engineers to prepare them for a challenging career in the field.

Currently, we have four turbomachinery service engineers in the U.S and three engineers in the U.K., with additional members of the team in Australia and the Middle East. Although John Crane’s engineers are based out of different regions, they travel around the globe to work on sites in remote and challenging environments, including cold and tropical water offshore platforms. This elite team completes over 150 site assignments each year.

What Does a Turbomachinery Services Engineer Do?

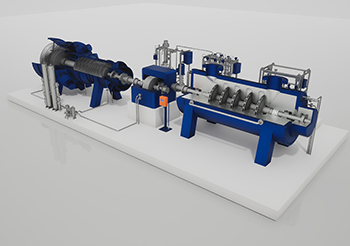

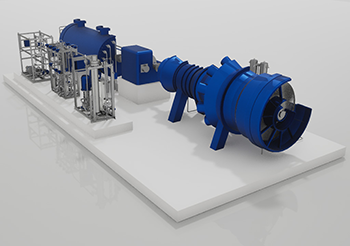

TSE’s provide critical services on turbomachinery equipment associated with centrifugal compressors, ranging from seal inspections, installations, start-ups and surveys on replacement seals. They also carry out services on dry gas seal support systems, including filter inspections and provide support with couplings and other turbomachinery components.

Armed with specialist product knowledge and engineering expertise, John Crane’s TSE’s provide customer training and consultancy to help end-users manage their compressor equipment safely and efficiently.

How Long Does It Take to Become a Turbomachinery Services Engineer?

John Crane’s engineers spend, on average, 7-10 months in training. They must complete over 45 online training courses to build up specialist product knowledge and awareness of site work best practice and compliance with John Crane’s working policies. They also spend between 17-24 weeks in different departments at John Crane, such as operations and engineering acquiring a breadth of technical expertise.

After the initial theory is completed, the trainee engineers undergo rigorous tests, such as medical and offshore survival training, to assess their fitness and to acquire the skills required to work in challenging and potentially hazardous environments.

Before graduating, they are mentored by qualified John Crane turbomachinery service engineers before finally conducting a series of supervised site visits, where their performance is rigorously assessed by their mentor and the head of the field services team.

Customer Focussed Above and Beyond

John Crane’s engineers spend 6-7 months a year overseas. They are on call 24/7, 365 days a year. They can be assigned to planned site visits, which are typically booked weeks in advance, or called out to unplanned site visits where there is little to no advance notice and the stakes are high.

Once on-site, our engineers typically work 10-to-12-hour days onshore and offshore, seven days a week for up to 21 days in total. Extensive travel is required, with prolonged periods of time spent away from home. As a small team, John Crane’s TSEs are 100% focused on supporting customers to the best of their abilities, no matter the location, time or day of the week.

Insights from the Field: A Conversation with Two Engineers

We asked two of our engineers, Shaun Goodwin and Matthew Lewins to talk to us about their experiences:

Q. What does it take to be a TSE at John Crane take?

Matthew: You need to be self-motivated and want to push yourself through the extended working hours on site, and then there’s the travel which can be tiring. I’d also say that you need to be very organized as this can help you cope with different situations.

Shaun: I’d agree. You could be sitting at home having your dinner and find out later that night, that you need to travel to Canada the next day - so you need to be prepared to leave at a moment’s notice. You also need to be very outgoing, but professional. And you need a sense of humor. That can help with walking into potentially charged situations on-site.

A lot of the work you do is quite solitary, so enjoying your own company is important. You might be working on an oil rig in the middle of the ocean and often just working on your own, and there’s a lot of waiting around for the work to get done too. But we keep in touch as a team and we’re always there to support each other. We’re sharing experiences and advice which is great.

Matthew: To add to Shaun’s comments, I think intelligence is a given. You often need to make executive decisions on your own, which can make or break an assignment, but if you can justify those decisions then that’s the most important thing

Q. What do you like best about being a TSE?

Shaun: You’re also traveling around the world, and I enjoy visiting different locations and experiencing different cultures.

Matthew: Yes, you get a fair bit of free time, and sometimes your assignment can be extended by a couple of days for yourself, where you can relax, do some sightseeing or take time out for yourself. You also get a fair bit of time in between assignments to see your family. In general, the benefits outweigh the drawbacks.

Shaun: I’d agree. I couldn’t go back to a 9-to-5-hour routine job.

Q: What advice would you give to young engineers considering a career at John Crane?

Matthew: I’d say that if you’re more than just the average engineer - ambitious, bright and you want to travel and see the world, that being a turbomachinery services engineer is something you should look into.

Shaun: Yes, it’s a long-term career and not something you should consider lightly, but if you’re going to be a field engineer then John Crane is a good place to be.

To find out more about being a Turbomachinery Services Engineer at John Crane contact nick.obrien@johncrane.com